A4 Mk2

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

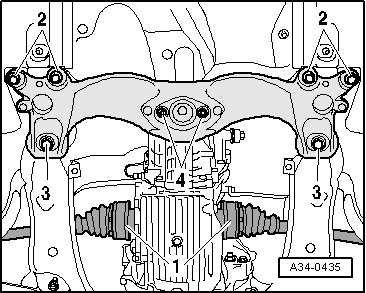

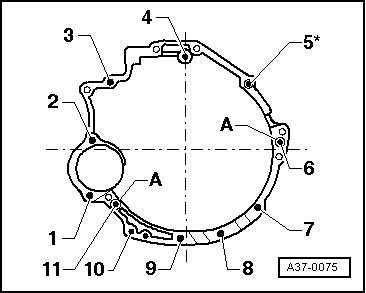

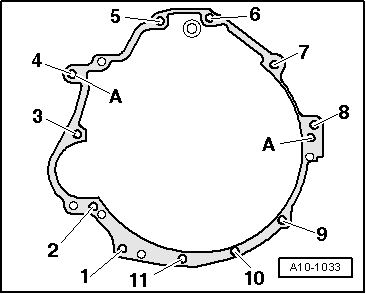

| Item | Bolt | Nm |

| 1 1) | M12 x 75 | 65 |

| 2 1) | M12 x 90 | 65 |

| 3 2) | M12 x 75 | 65 |

| 4, 6 | M12 x 90 | 65 |

| 5 2) | M12 x 110 | 65 |

| 7 3) | M10 x 50 | 45 |

| 8, 9, 10 | M10 x 45 | 45 |

| 11 4) | M12 x 110 | 65 |

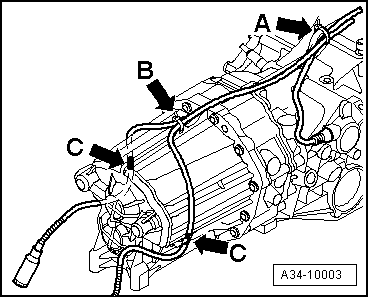

| A | Dowel sleeves for centralising | |

| 1) Secures starter to gearbox 2) With bracket for wiring harness 3) Hammer head bolt with nut 4) With nut | ||

|

|

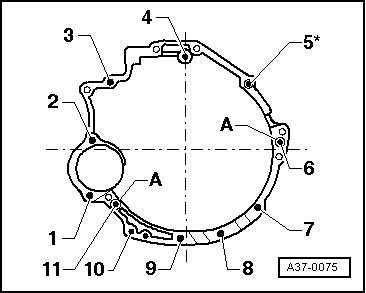

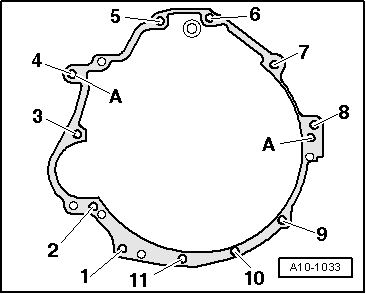

| Item | Bolt | Nm |

| 1 1) | M12 x 80 | 65 |

| 2 1) | M12 x 95 | 65 |

| 3 2) | M12 x 80 | 65 |

| 4, 6 | M12 x 95 | 65 |

| 5 2) | M12 x 110 | 65 |

| 7 3) | M10 x 50 | 45 |

| 8, 9, 10 | M10 x 45 | 45 |

| 11 4) | M12 x 110 | 65 |

| A | Dowel sleeves for centralising | |

| 1) Secures starter to gearbox 2) With bracket for wiring harness 3) Hammer head bolt with nut 4) With nut | ||

|

|

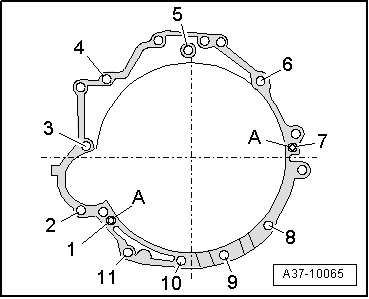

| Item | Bolt | Nm |

| 1 1) | M12 x 105 | 65 |

| 2 2) | M12 x 80 | 65 |

| 3 2) | M12 x 90 | 65 |

| 4 3) | M12 x 80 | 65 |

| 5, 7 | M12 x 95 | 65 |

| 6 3) | M12 x 105 | 65 |

| 8 4) | M10 x 50 | 45 |

| 9, 10, 11 | M10 x 45 | 45 |

| A | Dowel sleeves for centralising | |

| 1) With nut 2) Secures starter to gearbox 3) With bracket for wiring harness 4) Hammer head bolt with nut | ||

|

|

| Item | Bolt | Nm |

| 1, 9, 10, 11 | M10 x 60 | 45 |

| 2 1) | M10 x 150 | 65 |

| 3 | M12 x 130 | 65 |

| 4 … 6 | M12 x 80 | 65 |

| 7 | M12 x 100 | 65 |

| 8 | M12 x 90 | 65 |

| A | Dowel sleeves for centralising | |

| 1) Property class 10.9 | ||

|

|

| Item | Bolt | Nm |

| 1, 10, 11 | M10 x 60 | 45 |

| 2 1)2) | M10 x 150 | 65 |

| 3 1) | M12 x 130 | 65 |

| 4 | M12 x 85 | 65 |

| 5, 6 | M12 x 90 | 65 |

| 7 | M10 x 100 | 45 |

| 8 | M12 x 95 | 65 |

| 9 3) | M10 x 60 | 45 |

| A | Dowel sleeves for centralising | |

| 1) Secures starter to gearbox 2) Property class 10.9 3) Hammer head bolt with nut | ||

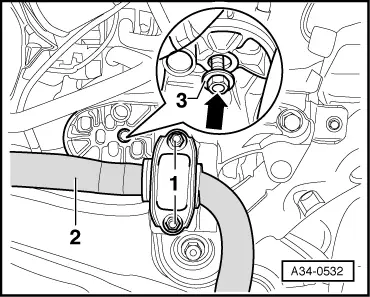

| Component | Nm |

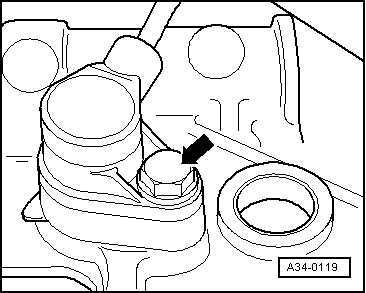

| Slave cylinder to gearbox | 23 1) |

| Gearbox selector lever to gearbox | 20 |

| Push rod to gearbox | 40 |

| Connecting rod for selector rod to gearbox | 20 |

| Gearbox mounting to gearbox | 23 |

| Tunnel cross member to gearbox mounting | 23 |

| Heat shields above drive shafts to gearbox | 23 |

| Engine mounting to engine support | 23 |

| Torque reaction support to engine (Cabriolet only) | 30 + 90° 1) |

| Bracket for noise insulation to subframe | 10 |

| 1) Renew bolt | |

Caution

Caution