| –

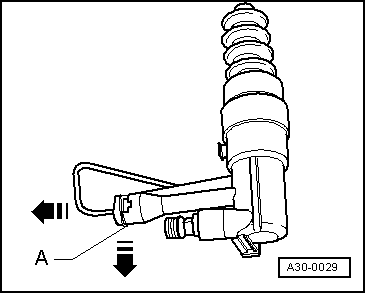

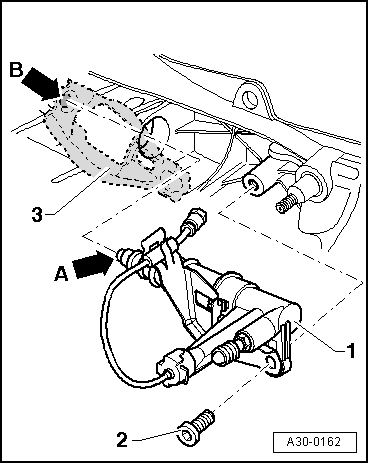

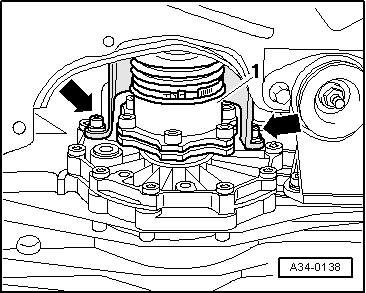

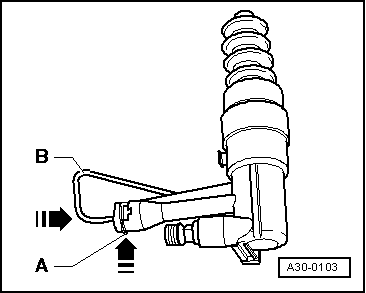

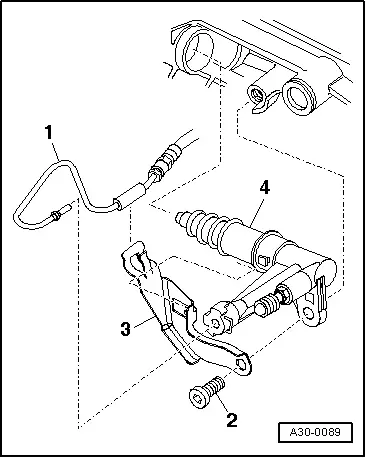

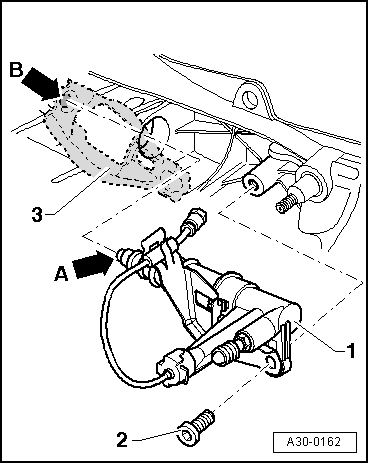

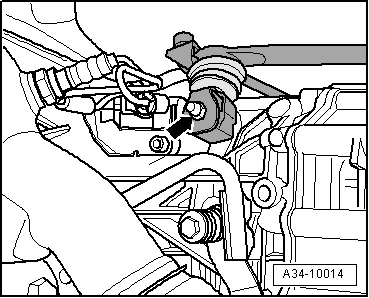

| Guide slave cylinder -1- into mounting hole in gearbox housing, keeping it as far as possible in line with the operating direction of the plunger -arrow A-. |

| –

| At the same time insert in recess -arrow B- on clutch release lever -3-. |

| –

| Secure slave cylinder -1- with new bolt -2-. Tightening torque → Item |

Note | If the slave cylinder -1- is inserted at an angle, there is a danger that the plunger -arrow A- will be guided past the clutch release lever -3-. |

Caution | t

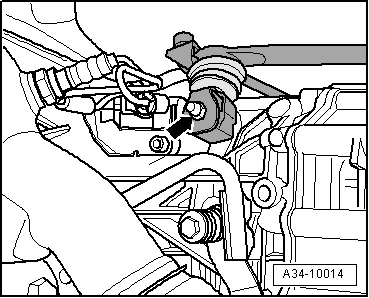

| After installing the slave cylinder carefully press the clutch pedal. |

| t

| If you feel an unusually strong point of resistance when depressing the clutch pedal, you must not press it down further. |

| t

| The plunger of the slave cylinder is likely to have been guided past the clutch release lever. |

| t

| The slave cylinder would then be destroyed once pedal force exceeds approx. 300 N. |

| t

| For comparison: normal pedal force is approx. 115 N. |

|

| –

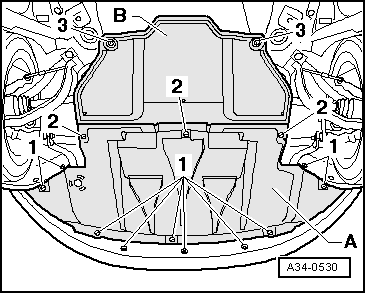

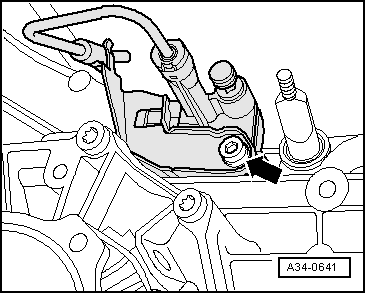

| If the pipe-hose assembly was disconnected at the slave cylinder, the clutch system has to be bled after installing slave cylinder → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution