A4 Mk2

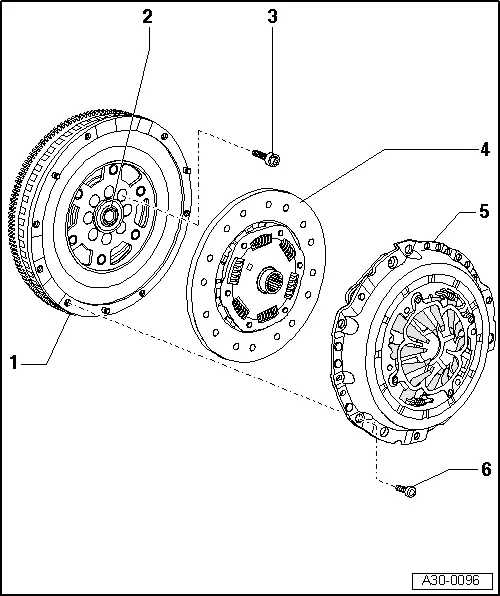

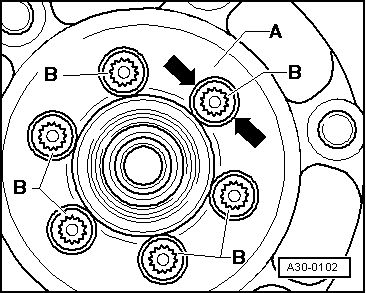

| Exploded view - servicing clutch with SAC pressure plate (LuK version) |

| t | Observe notes → Chapter „Servicing clutch“. |

| t | The gearbox has to be removed before working on the clutch → Chapter. |

| t | „SAC“ stands for „Self-Adjusting Clutch“. |

| 1 - | Dual-mass flywheel |

| q | Ensure that dowel pins fit tightly |

| q | Contact surface for clutch lining must be free of grooves, oil and grease |

| q | Observe instructions for removal → Fig. |

| q | Removing and installing → Rep. gr.13 |

| 2 - | Needle bearing |

| q | Removing and installing → Rep. gr.13 |

| 3 - | Bolt |

| q | For flywheel |

| q | Renew |

| q | Tightening torque for bolt length 22.5 mm: 60 Nm + 90° further |

| q | Tightening torque for bolt length 43 mm: 60 Nm + 180° further |

| q | Observe instructions for removal → Fig. |

| 4 - | Clutch plate |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Installation position: Clutch lining must make full contact with flywheel |

| q | The marking „Getriebeseite“ (gearbox side), if provided, faces towards pressure plate/gearbox |

| q | Coil springs (damper assembly) point towards pressure plate and gearbox |

| q | Centralising → Anchor |

| q | Lightly grease splines → Anchor |

| 5 - | SAC pressure plate |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Observe assembly instructions → Chapter when removing and installing |

| q | Resetting adjuster ring → Chapter |

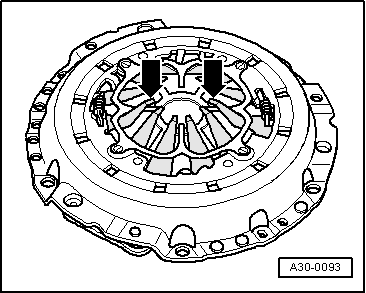

| q | Checking ends of diaphragm spring → Fig. |

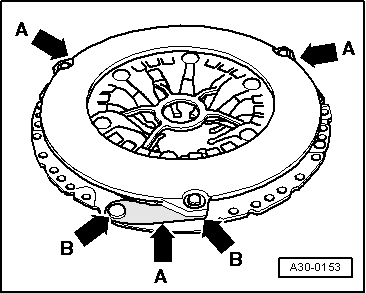

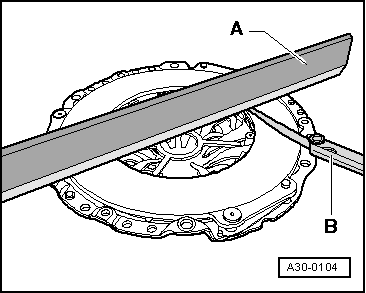

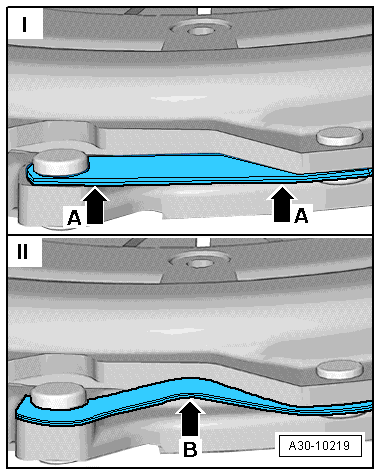

| q | Checking pressure plate for distortion → Fig. |

| q | Checking springs and riveting → Fig. |

| q | Contact surface for clutch lining must be free of grooves, oil and grease |

| 6 - | Bolt |

| q | 22 Nm |

| q | Observe instructions for installation → Chapter |

Note

Note

|

|

|

|

|

|

|

|

Caution

Caution