A4 Mk2

| Exploded view - dismantling and assembling differential |

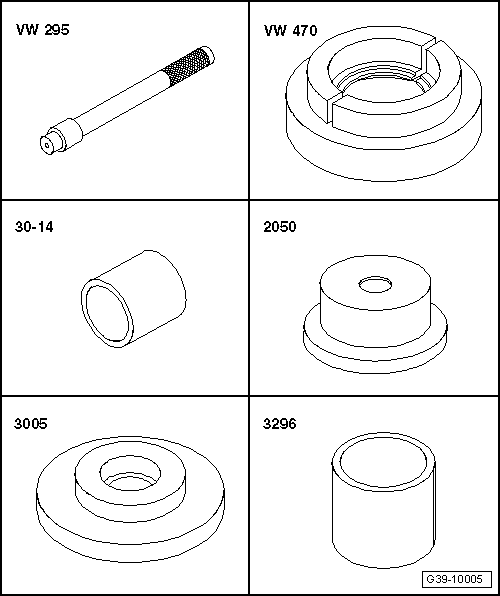

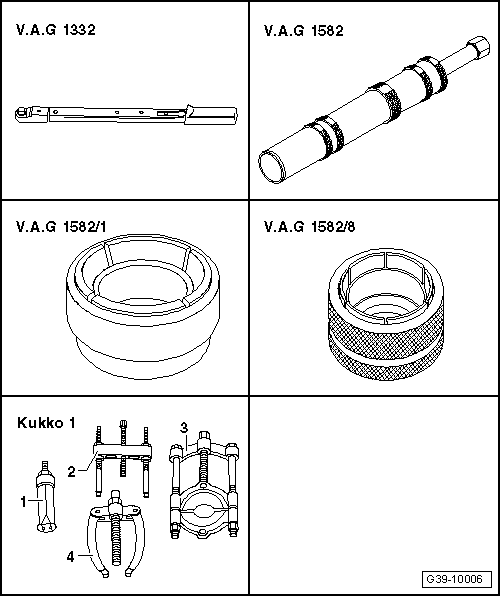

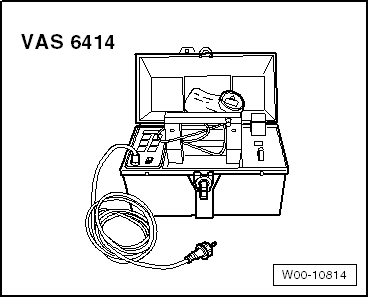

| Special tools and workshop equipment required |

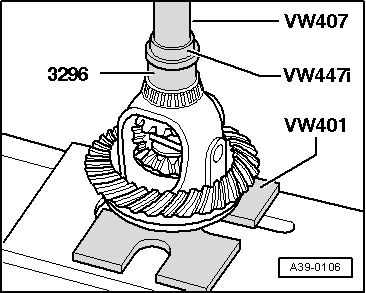

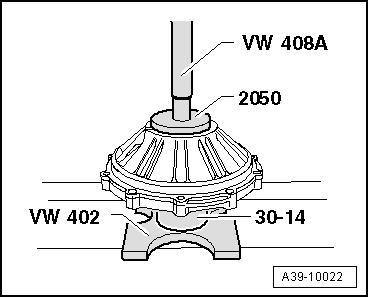

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 408 A- |

| t | Thrust plate -VW 447 H- |

| t | Thrust plate -VW 447 i- |

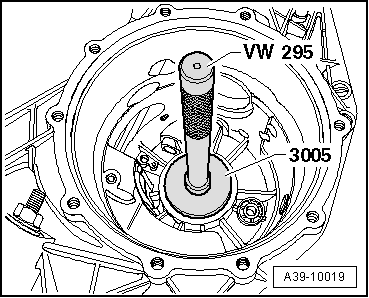

| t | Drift -VW 295- |

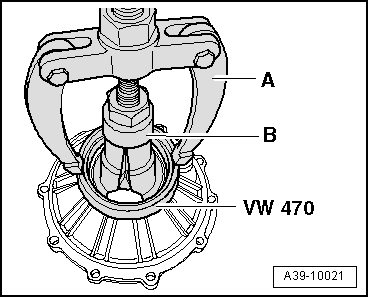

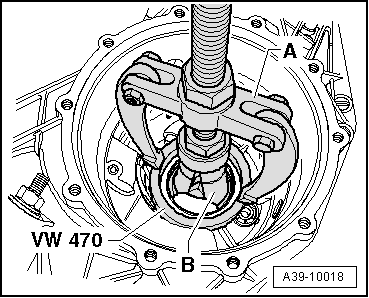

| t | Thrust pieces for pinion shaft bearing -VW 470- |

| t | Tube -30 - 14- |

| t | Thrust piece -2050- |

| t | Thrust plate -3005- |

| t | Tube -3296- |

| t | Torque wrench -V.A.G 1332- |

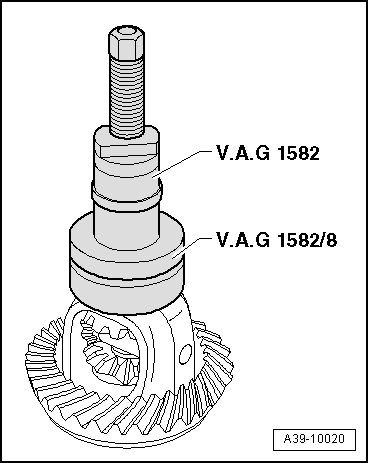

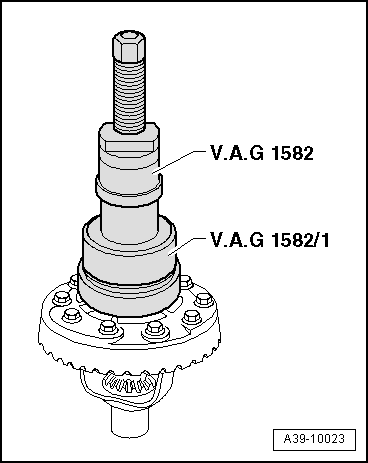

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/1- |

| t | Adapter -V.A.G 1582/8- |

| t | -1-Internal puller -Kukko 21/8- |

| t | -4-Counter-support -Kukko 22/2- |

|

|

|

|

| Removing and installing differential → Chapter |

Note

Note| t | Always renew both tapered roller bearings together. |

| t | Adjustment work is required when renewing the parts marked with 1). Table of adjustments → Chapter |

| 1 - | Gearbox housing 1) |

| 2 - | Shim „S2“ |

| q | Note thickness |

| q | Table of adjustments → Chapter |

| 3 - | Outer race for tapered roller bearing (right-side) 1) |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| 4 - | Inner race for tapered roller bearing (right-side) 1) |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

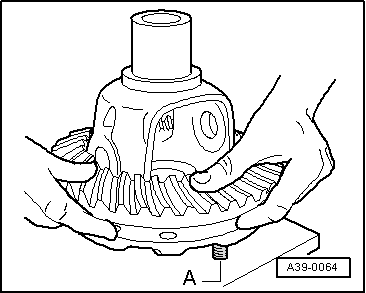

| 5 - | Crown wheel1) |

| q | Is paired with pinion shaft (final drive gear set) |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| q | Drive crown wheel off differential cage using a punch → Fig. |

| q | Fitting on differential cage → Fig. |

| 6 - | Differential cage1) |

| 7 - | Bolt |

| q | 60 Nm and turn 45° further |

| q | Renew |

| q | Tighten bolts in stages and in diagonal sequence until crown wheel makes full contact with differential cage. Then tighten to specified torque. |

| 8 - | Inner race for tapered roller bearing (left-side) 1) |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 9 - | Outer race for tapered roller bearing (left-side) 1) |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 10 - | Shim „S1“ |

| q | Note thickness |

| q | Table of adjustments → Chapter |

| 11 - | Cover for final drive 1) |

| q | With O-ring |

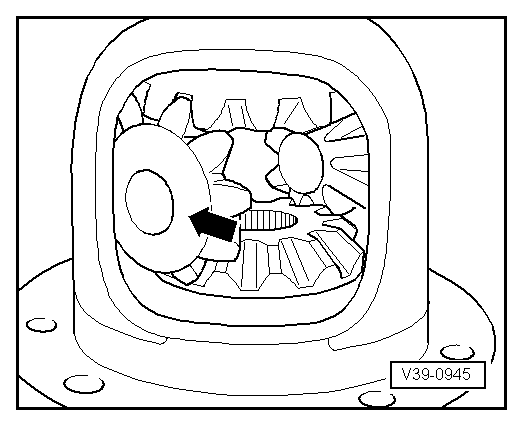

| 12 - | One-piece thrust washer |

| q | Lubricate with gear oil before installing |

| 13 - | Sun wheel |

| q | Installing → Fig. |

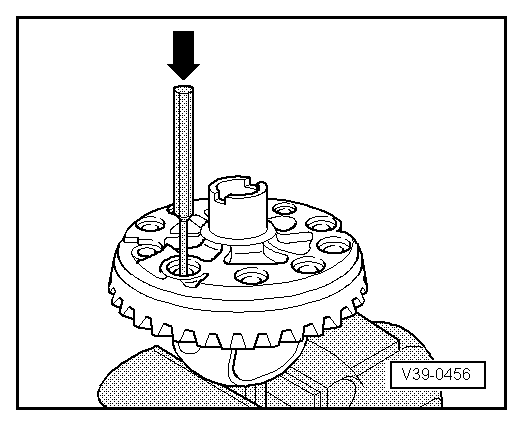

| 14 - | Differential pinion pin |

| q | Drive out with drift after removing spring pin |

| 15 - | Spring pin |

| q | Secures differential pinion pin |

| q | Drive out of differential cage with drift |

| q | Press in until 1.5 mm above differential cage |

| 16 - | Planet pinion |

| q | Installing → Fig. |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING