| –

| Lightly oil outer circumference of new oil seal. |

| –

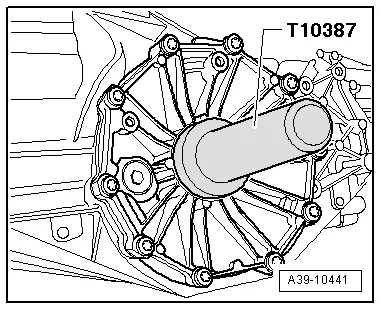

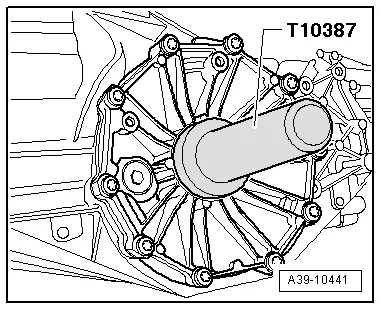

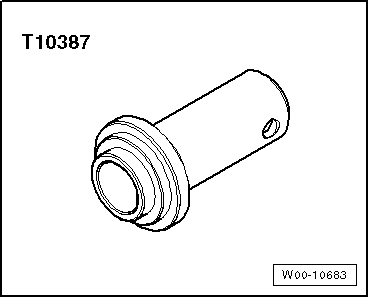

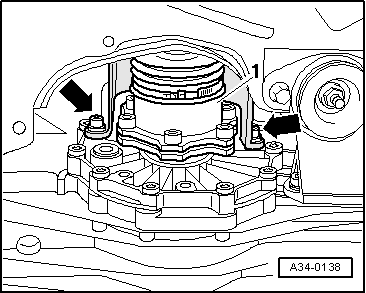

| Drive in new flange shaft oil seal using thrust piece -T10387- until thrust piece reaches stop; keep seal straight when installing. |

Note | t

| Driving-in depth (standard): 5.5 mm beneath surface of cover |

| t

| When carrying out a repair, the oil seal is driven in to a depth of 6.5 mm using thrust piece -T10387-, so that the new seal does not bear on the same contact surface on the used flange shaft. |

| –

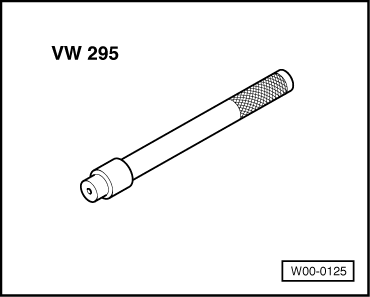

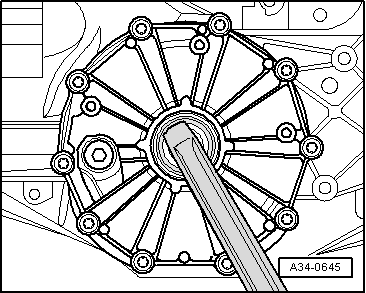

| Knock flange shaft in with drift -VW 295-. |

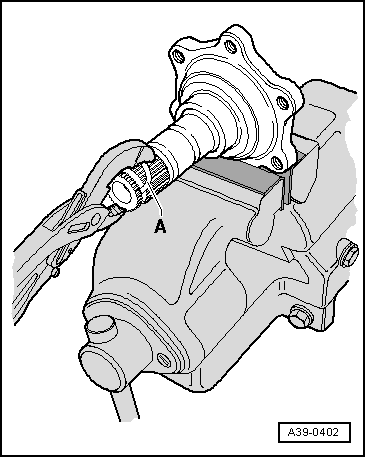

| The remaining installation steps are carried out in the reverse sequence; note the following points: |

| –

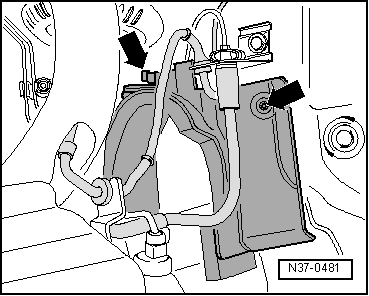

| Bolt on heat shield for drive shaft (left-side). |

| –

| Check oil level in gearbox and top up with gear oil if necessary → Chapter. |

| –

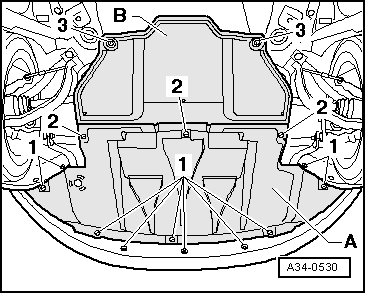

| Install noise insulation panels. |

|

|

|

Note

Note