| t

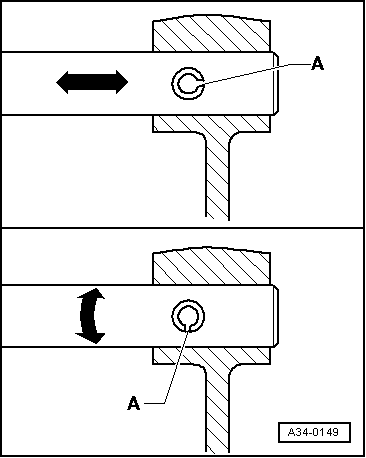

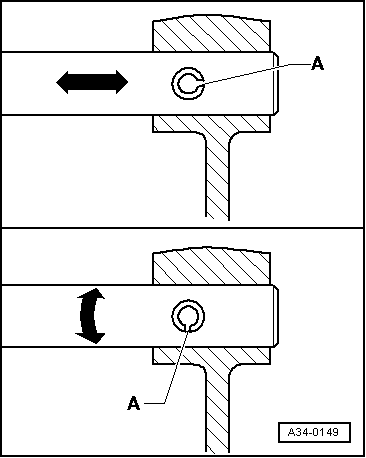

| When installing the gearbox, ensure that the dowel sleeves between the engine and the gearbox are correctly located. |

| t

| When installing mounting brackets as well as other waxed components, the contact surfaces must be cleaned. The contact surfaces must be free of wax and grease. |

| t

| When installing a new gearbox, check the oil level and fill up with oil if necessary → Chapter. |

| t

| Thoroughly clean all joints and connections and the surrounding areas before dismantling. |

| t

| Thoroughly clean housing contact surfaces before applying sealing paste. |

| t

| Apply sealing paste -AMV 188 001 02- evenly and not too thickly. |

| t

| Breather holes must remain free of sealing paste. |

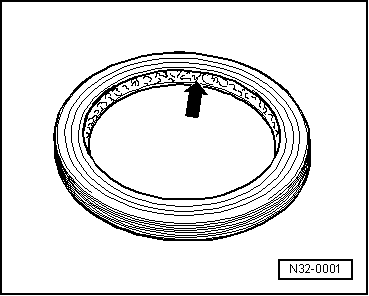

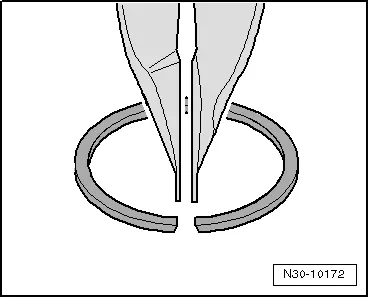

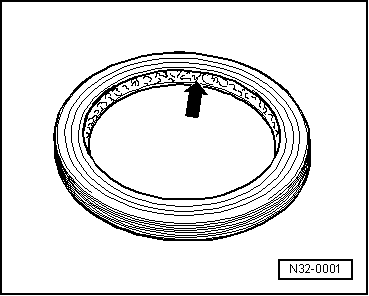

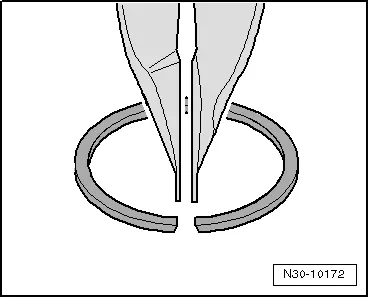

| O-rings, oil seals and gaskets |

| t

| Always renew O-rings, oil seals and gaskets. |

| t

| After removing gaskets and oil seals, always inspect the contact surface on the housing or shaft for burrs resulting from removal or for other signs of damage. |

| t

| Thoroughly clean housing joint surfaces before assembling. |

|

|

|