| –

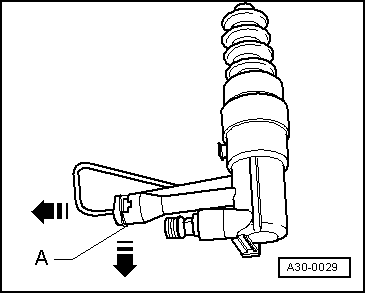

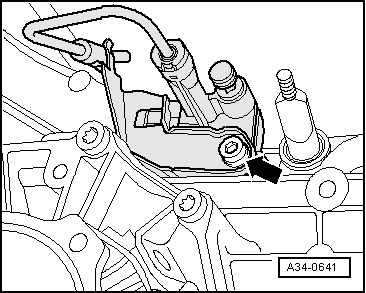

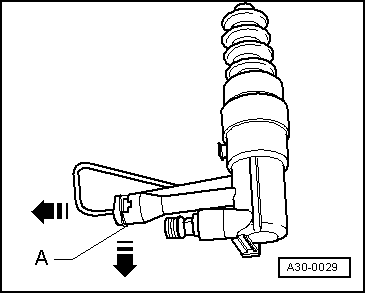

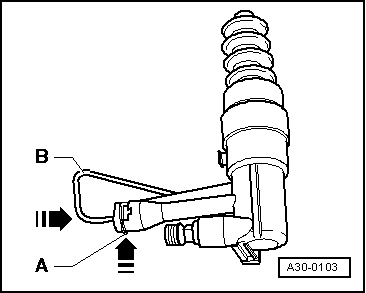

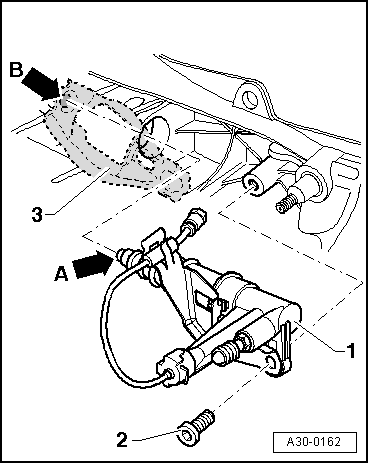

| To remove hose/pipe assembly, use a screwdriver to lever off clip -A- as far as the stop. Only then can the hose/pipe assembly be pulled out. |

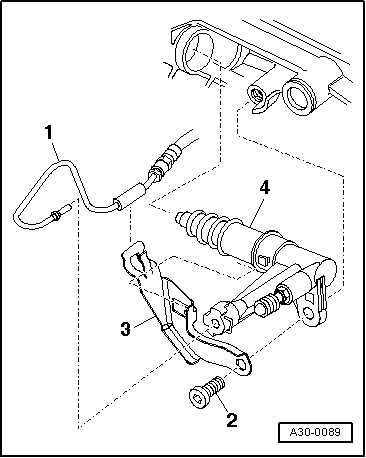

| Installation is carried out in reverse sequence; note the following: |

Note | t

| Do not allow brake fluid to come into contact with the gearbox. If necessary, clean the gearbox housing. |

| t

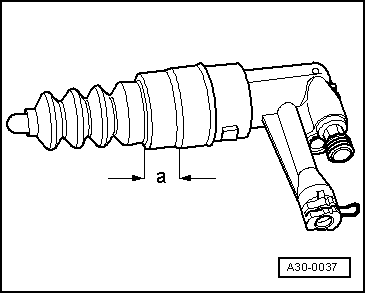

| If the clutch slave cylinder is inserted at an angle, there is a danger that the plunger will be guided past the clutch release lever. |

| t

| To facilitate assembly, engage 6th gear before fitting slave cylinder. |

| t

| When installing, press in slave cylinder so that securing bolt can be fitted easily. |

| t

| Renew securing bolt for slave cylinder. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution