A4 Mk2

| Removing gearbox - vehicles with 3.0 ltr. TDI engine |

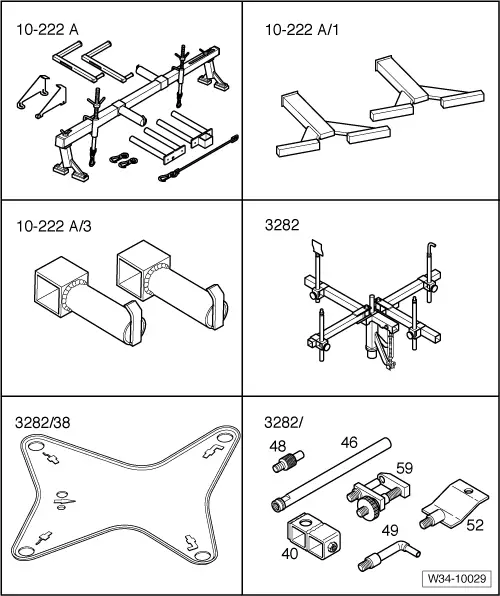

| Special tools and workshop equipment required |

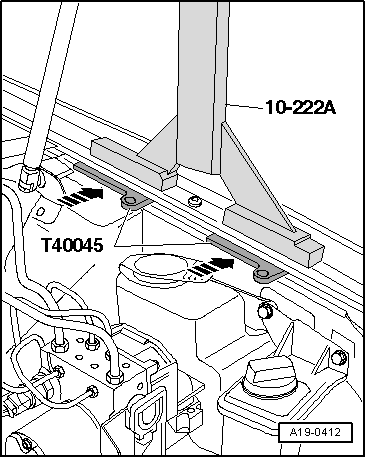

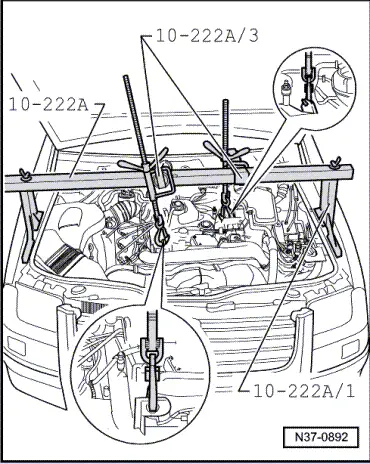

| t | Support bracket -10-222 A- |

| t | Rack -10-222 A /1- |

| t | Adapter -10-222 A /3- |

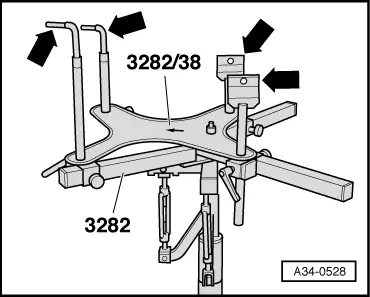

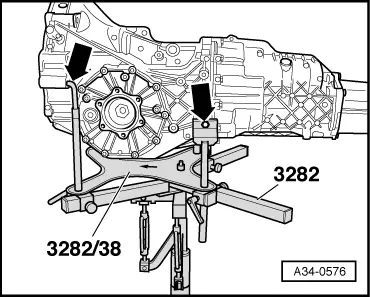

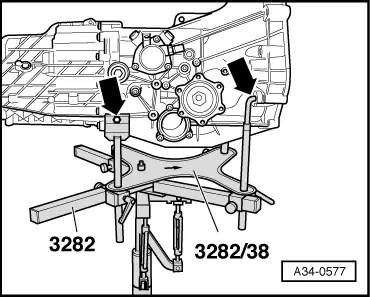

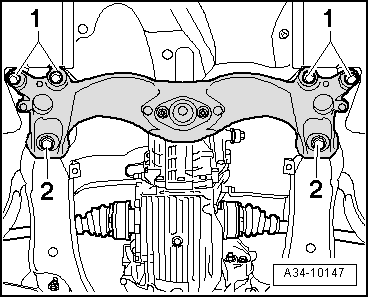

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/38- |

| t | Mounts -3282/49- (2x) |

| t | Mounts -3282/52- (2x) |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING