A4 Mk2

| Removing gearbox - vehicles with 8-cyl. MPI engine (Audi S4) |

| Special tools and workshop equipment required |

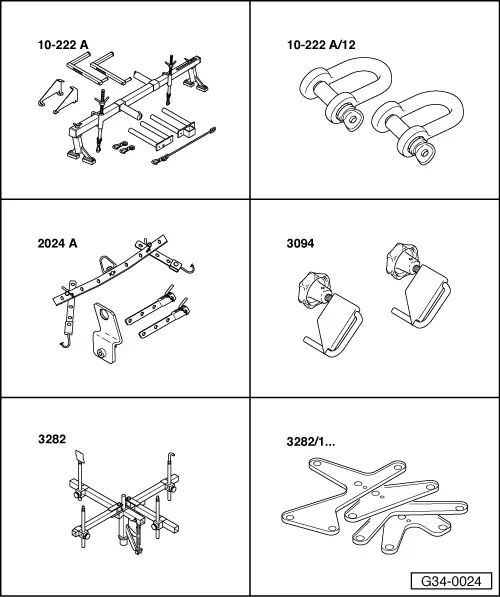

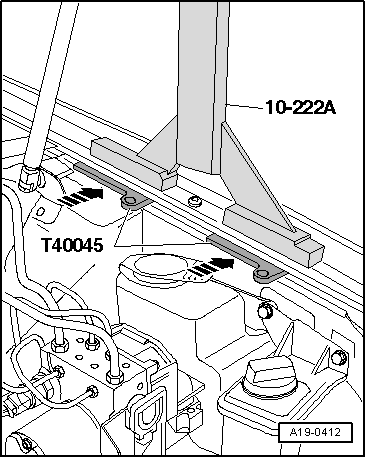

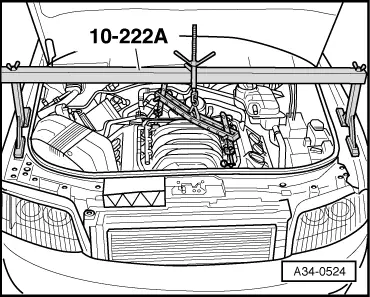

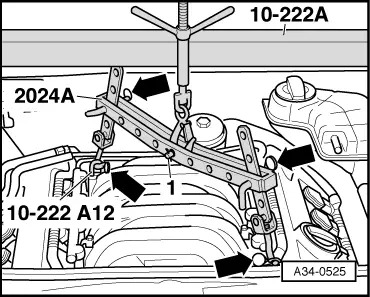

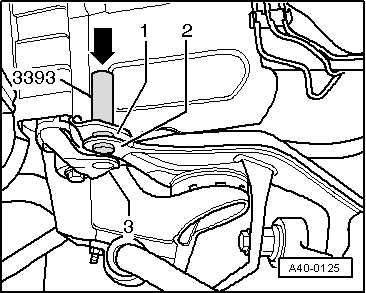

| t | Support bracket -10-222 A- |

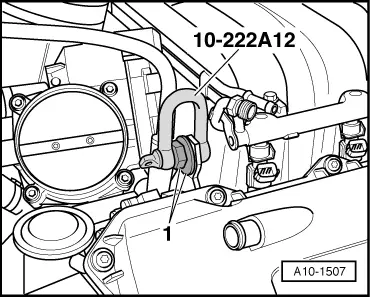

| t | Shackle -10-222 A /12- |

| t | Lifting tackle -2024 A- |

| t | Hose clamps, up to Ø 25 mm -3094- |

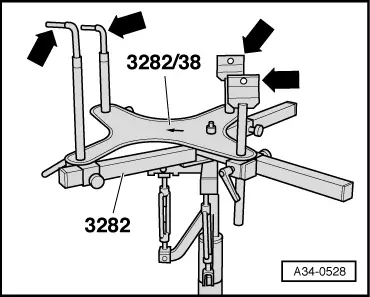

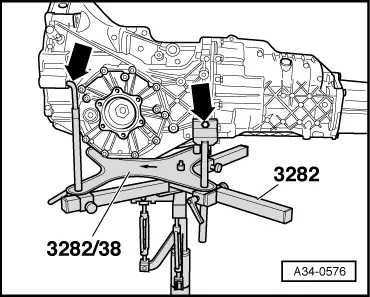

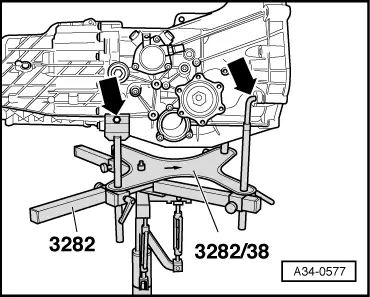

| t | Gearbox support -3282- |

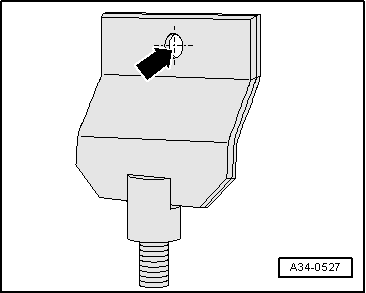

| t | Adjustment plate -3282/38- |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING