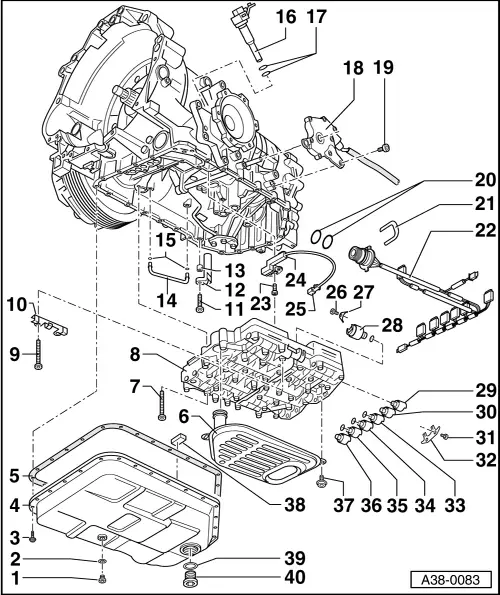

A4 Mk2

| Exploded view - hydraulic control components |

| 1 - | ATF drain plug, 40 Nm |

| q | Hexagon socket, 5 mm |

| 2 - | Seal |

| q | Renew |

| 3 - | Bolt, 10 Nm |

| q | Tighten in stages and in diagonal sequence |

| 4 - | Oil pan |

| q | Removing and installing → Chapter |

| 5 - | Gasket |

| q | Renew |

| 6 - | ATF strainer |

| q | Removing and installing → Chapter |

| 7 - | Bolt, 8 Nm |

| q | For securing valve body |

| M6 x 30 mm (1x) |

| M6 x 60 mm (16x) |

| q | Follow correct tightening sequence → Servicing automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.38 |

| 8 - | Valve body |

| q | Removing and installing → Servicing automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.38 |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue |

| 9 - | Bolt, 8 Nm |

| 10 - | Bracket |

| q | For wiring harness |

| q | Engage wiring harness on bracket |

| q | Secured with bolts for valve body |

| 11 - | Bolt, 6 Nm |

| 12 - | Gearbox output speed sender -G195- |

| q | Removing and installing → Servicing automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.38 |

| 13 - | Spacer sleeve |

| q | Length: 8 mm |

| 14 - | Internal oil pipe |

| q | Renew |

| q | Removing and installing → Servicing automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.38 |

| 15 - | O-ring |

| q | Renew |

| 16 - | Speedometer sender -G22- |

| q | Not fitted on all versions. If the gearbox has no -G22-, the road speed signal is taken from the ABS/ESP control unit and transmitted to the relevant control units via CAN bus |

| q | Gearbox without speedometer sender -G22- → Chapter |

| q | Removing and installing → Chapter |

| 17 - | O-ring |

| q | Renew |

| q | Lubricate with ATF when installing |

| 18 - | Multifunction switch -F125- |

| q | Removing and installing → Chapter |

| q | Renewing oil seal for selector shaft → Chapter |

| 19 - | Bolt, 8 Nm |

| 20 - | O-ring |

| q | Renew |

| 21 - | Retaining clip |

| 22 - | Wiring harness in gearbox |

| q | Gearbox oil temperature sender -G93- integrated in wiring harness |

| q | Removing and installing → Servicing automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.38 |

| q | Disengage from bracket → Item |

| q | Position of wiring harness connector: flat part of rear collar faces towards oil pan; lugs on collar are horizontal |

| 23 - | Bolt, 9 Nm |

| 24 - | Gearbox input speed sender -G182- |

| q | Removing and installing → Servicing automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.38 |

| 25 - | Connector |

| q | Is connected to wiring harness in gearbox |

| q | Has to be disconnected before removal of valve body |

| 26 - | Bolt, 6 Nm |

| 27 - | Bracket |

| q | For solenoid valve |

| 28 - | Solenoid valve 4 -N91- |

| q | With O-ring |

| q | Removing and installing → Servicing automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.38 |

| 29 - | Solenoid valve 3 -N90- |

| q | Without O-ring |

| q | Removing and installing → Chapter „Removing and installing oil pan“ |

| 30 - | Solenoid valve 2 -N89- |

| q | Without O-ring |

| q | Removing and installing → Chapter „Removing and installing oil pan“ |

| 31 - | Bolt, 6 Nm |

| 32 - | Bracket |

| q | For solenoid valves |

| 33 - | Solenoid valve 6 -N93- |

| q | With O-ring |

| q | Removing and installing → Chapter „Removing and installing oil pan“ |

| 34 - | Solenoid valve 7 -N94- |

| q | With O-ring |

| q | Removing and installing → Chapter „Removing and installing oil pan“ |

| 35 - | Solenoid valve 5 -N92- |

| q | With O-ring |

| q | Removing and installing → Chapter „Removing and installing oil pan“ |

| 36 - | Solenoid valve 1 -N88- |

| q | Without O-ring |

| q | Removing and installing → Chapter „Removing and installing oil pan“ and detach guide plate for parking lock mechanism |

| q | When installing, do not tighten bolts for guide plate (23 Nm) with selector lever in “P” |

| 37 - | Bolt, 6 Nm |

| 38 - | Magnet |

| q | 4 x, in recesses in oil pan |

| 39 - | O-ring |

| q | Renew |

| 40 - | ATF inspection plug, 80 Nm |

| q | Hexagon socket, 17 mm |