| –

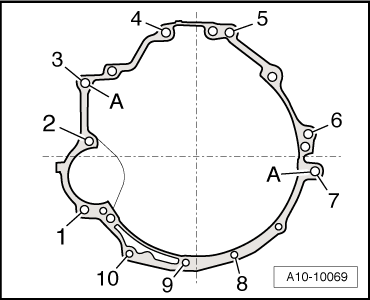

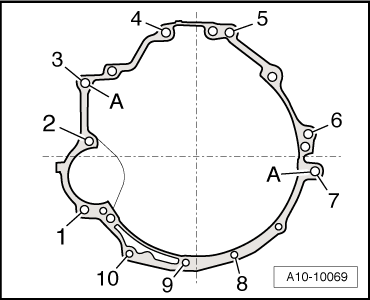

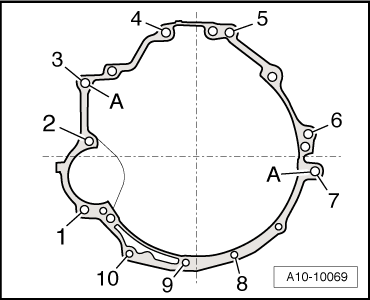

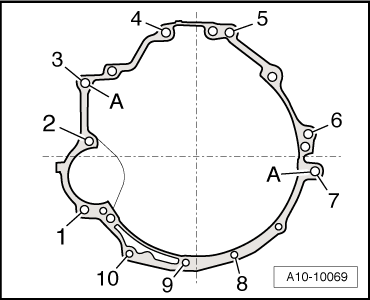

| Before installing gearbox, check for correct positioning of dowel sleeves -A- at cylinder block. Install new dowel sleeves if necessary. |

| –

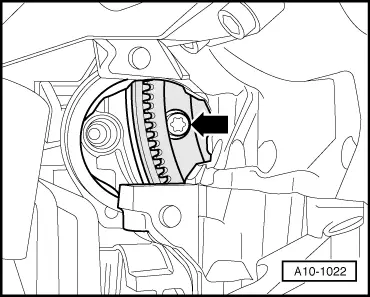

| Install intermediate plate between engine and gearbox in the original position. |

| –

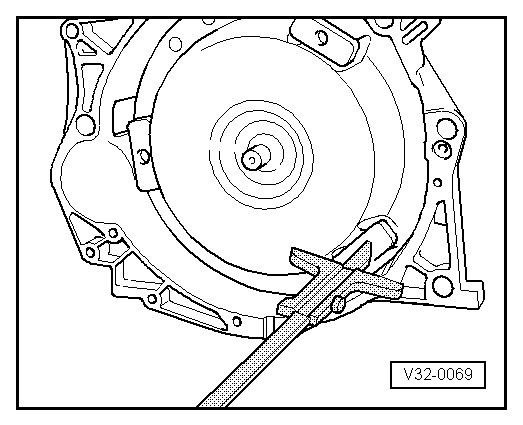

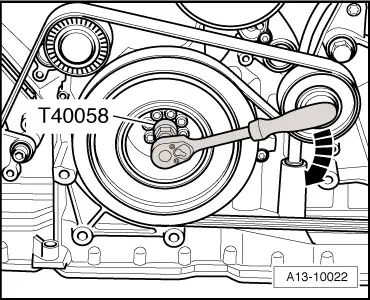

| Before joining engine and gearbox, turn torque converter and drive plate (on engine) until one hole and one tapped hole are in line with the opening for the removed starter. |

| –

| When pushing the engine and gearbox together, ensure that no wiring or pipes etc. can become trapped. |

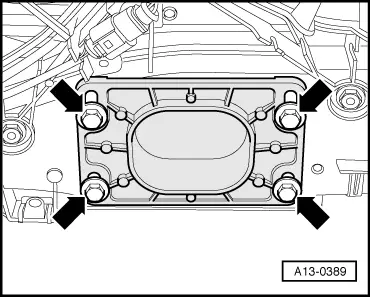

| When you then install the gearbox, adhere to the following instructions. |

Caution | Before and while you are tightening the bolts on the engine/gearbox flange keep checking that the torque converter can still be rotated behind the drive plate. If the converter cannot be turned, it must be assumed that it has not been installed correctly and the drive lugs on the converter or the ATF pump will be damaged when the bolts are fully tightened. |

|

|

|

|

Note

Note

Note

Note

Caution

Caution