A4 Mk2

|

| Special tools and workshop equipment required |

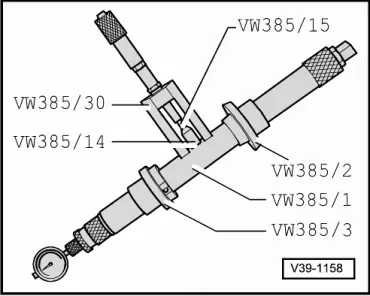

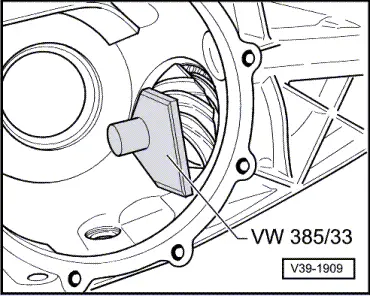

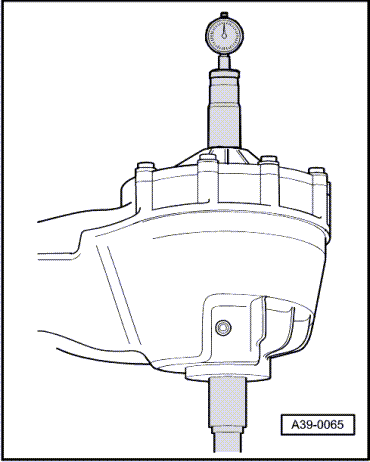

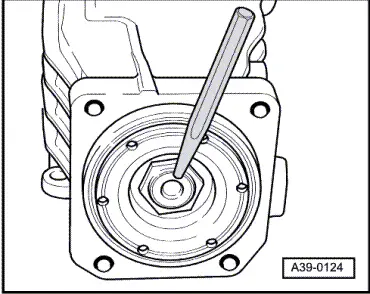

| t | Universal measuring tool -VW 385- |

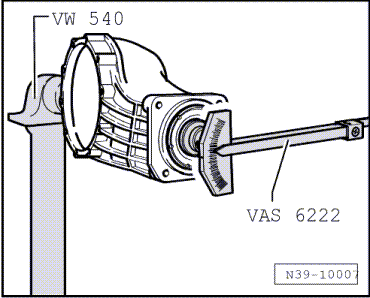

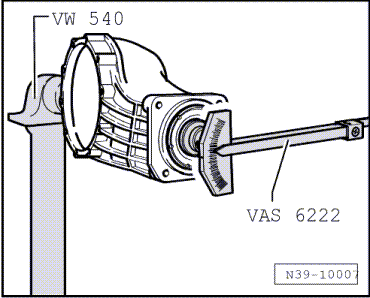

| t | Engine and gearbox support -VW 540- |

| t | Bearing preload gauge -VAS 6222- |

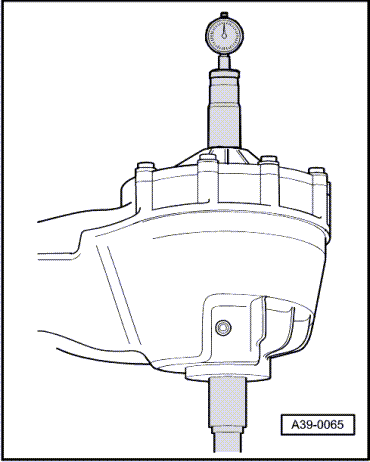

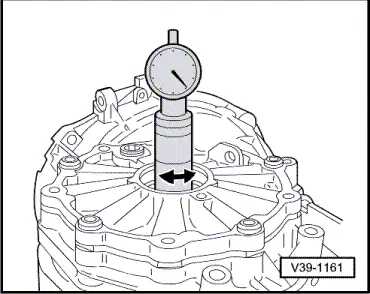

| t | Dial gauge |

| t | Socket (long) -SW 36- |

|

|

|

|

|

| New bearings | Used bearings → Note |

| 150 … 200 Ncm | 30 … 60 Ncm |

|

|

|

|

|

|

|

|

|

|

|

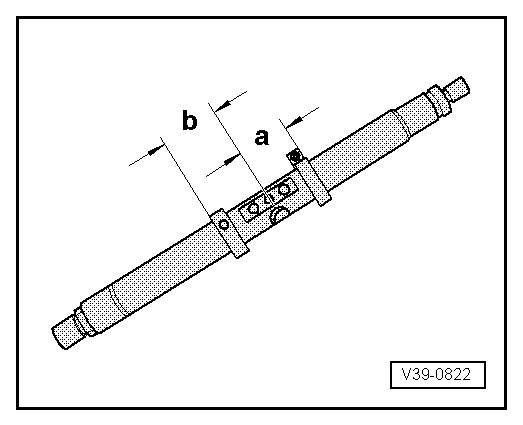

| e | - | Measured value (maximum deflection) |

| r | - | Allowance (marked on crown wheel in 1/100 mm) |

|

| Dial gauge reading “e” | 1.60 mm |

| Allowance “r” marked on crown wheel | – 0.42 mm |

| Shim thickness “S3” | = 1.18 mm |

|

| Shim thickness (mm) | ||

| 0.95 | 1.20 | 1.45 |

| 1.00 | 1.25 | 1.50 |

| 1.05 | 1.30 | 1.55 |

| 1.10 | 1.35 | |

| 1.15 | 1.40 | |

|

|

|

| New bearings | Used bearings → Note |

| 150 … 200 Ncm | 30 … 60 Ncm |

|

|

|

|

|

WARNING

WARNING Caution

Caution