A4 Mk2

| Removing and installing differential |

| Special tools and workshop equipment required |

| t | Drift -VW 295- |

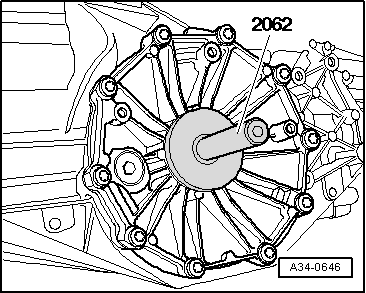

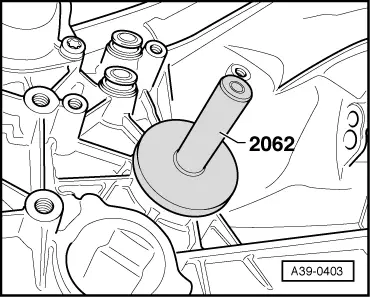

| t | Punch -2062- |

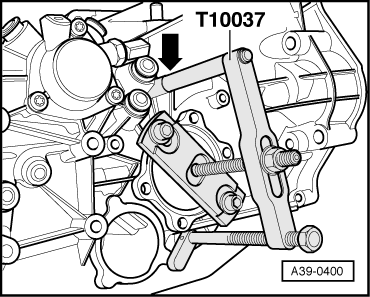

| t | Puller -T10037- |

| t | Sealing grease -G 052 128 A1- |

Note

Note| t | Removing and installing is possible with the gearbox installed. |

| t | The differential can be removed and installed without removing the selector mechanism, input shaft, pinion shaft or gearbox cover. These components must be removed if the differential needs to be adjusted. |

| t | Adjustment work is required when renewing the parts marked with 1). Table of adjustments → Chapter. |

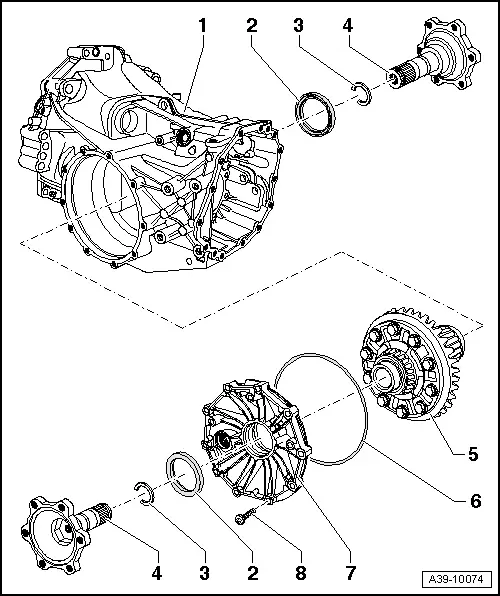

| 1 - | Gearbox housing 1) |

| 2 - | Oil seal |

| q | Removing → Fig. |

| q | Installing (left-side) → Fig. |

| q | Installing (right-side) → Fig. |

| 3 - | Circlip |

| q | Renew |

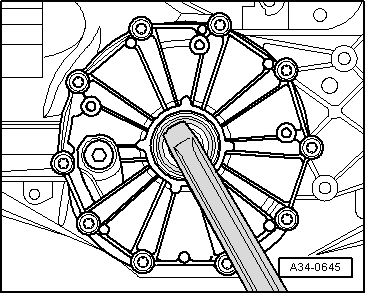

| q | Removing and installing → Fig. |

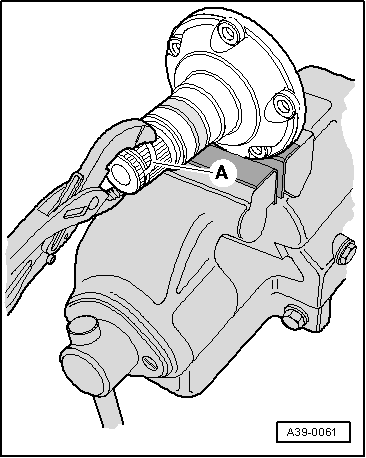

| 4 - | Flange shaft |

| q | Removing (left-side) → Fig. |

| q | Removing (right-side) → Fig. |

| q | Drive in with drift -VW 295- |

| 5 - | Differential with crown wheel1) |

| q | Dismantling and assembling → Chapter |

| 6 - | O-ring |

| q | Always renew |

| q | Lubricate with gear oil |

| 7 - | Cover for final drive1) |

| 8 - | Torx bolt, 24 Nm |

|

|

|

|

|

|

|

|

|

|