A4 Mk2

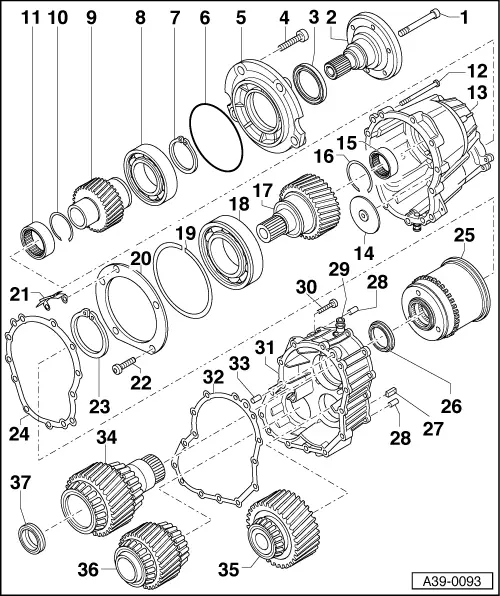

| Front axle drive and transfer box - exploded view of components |

Note

Note| The parts shown in the illustration can be removed without removing the gearbox from the vehicle. |

| 1 - | Hexagon socket head bolt, 25 Nm |

| 2 - | Output flange for propshaft |

| 3 - | Oil seal |

| q | Renew → Automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.39 |

| 4 - | Bolt, 23 Nm |

| q | 4 x |

| 5 - | Housing cover |

| 6 - | O-ring |

| q | Lubricate with gear oil |

| 7 - | Circlip |

| 8 - | Grooved ball bearing |

| q | For spur gear 1 |

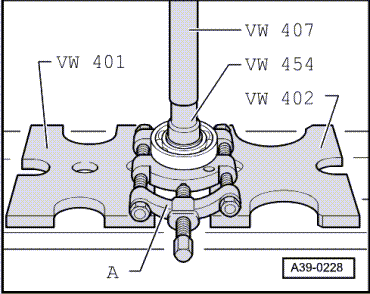

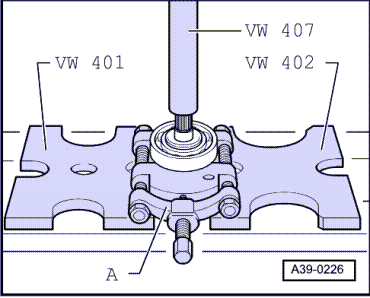

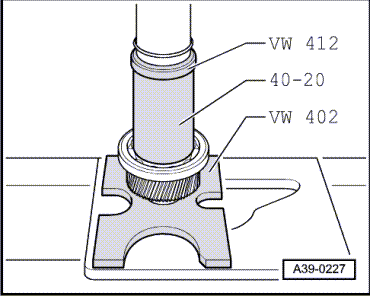

| q | Pressing off → Fig. |

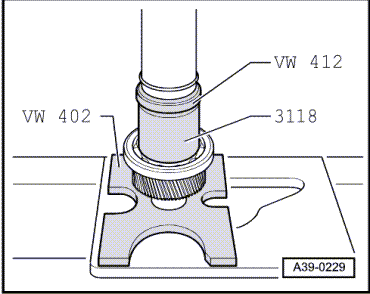

| q | Pressing on → Fig. |

| 9 - | Spur gear 1 |

| q | For rear axle drive |

| q | If damaged, always renew together with spur gear 2 → Item |

| q | To remove, pull out of transfer box housing towards the rear, together with → Item and → Item |

| 10 - | Circlip |

| 11 - | Needle bearing |

| q | For spur gear 1 |

| q | Only remove bearing in order to renew |

| q | To renew, heat transfer box housing to approx. 100 °C and drive out needle bearing towards the rear with suitable drift (Warning: wear protective gloves) |

| q | Drive in onto stop using sleeve -30-21- |

| 12 - | Bolt, 23 Nm |

| q | Loosen and tighten in diagonal sequence |

| 13 - | Transfer box housing |

| q | Can be renewed if damaged |

| 14 - | Tensioning nut |

| q | Output flange for propshaft → Item |

| 15 - | Needle bearing |

| q | For spur gear 2 → Item |

| q | Only remove bearing in order to renew |

| q | Renewing → Chapter |

| 16 - | Circlip |

| q | Secures needle bearing → Item in transfer box housing → Item |

| 17 - | Spur gear 2 |

| q | For rear axle drive |

| q | If damaged, always renew together with spur gear 1 → Item |

| q | To renew, remove transfer box → Automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.39 and pull out together with → Item and → Item |

| 18 - | Grooved ball bearing |

| q | For spur gear 2 |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 19 - | Circlip |

| q | Secures grooved ball bearing → Item in transfer box housing |

| 20 - | Securing plate |

| q | For grooved ball bearing → Item |

| q | Before installing, clip alignment plate → Item onto securing plate |

| 21 - | Alignment plate |

| 22 - | Bolt, 8 Nm |

| q | For securing plate → Item |

| 23 - | Circlip |

| q | Secures grooved ball bearing → Item on spur gear 2 → Item |

| 24 - | Gasket |

| q | Renew → Automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.39 |

| 25 - | Torsen differential |

| q | Renew as complete unit if damaged |

| q | Removing and installing → Automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.39. |

| 26 - | Oil seal |

| q | Renewing → Chapter |

| 27 - | Magnet |

| q | Installing → Automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.39 |

| 28 - | Dowel sleeve |

| q | 2 x |

| 29 - | Breather |

| q | For transfer box |

| q | With fitted cap |

| q | Installation position: breather without cap must project 10 ... 11 mm from housing |

| 30 - | Bolt, 23 Nm |

| q | Loosen and tighten in diagonal sequence |

| 31 - | Intermediate flange for front axle drive |

| q | Removing and installing → Automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.39. |

| 32 - | Gasket |

| q | Renew → Automatic gearbox 01V, front-wheel drive and four-wheel drive; Rep. Gr.39 |

| 33 - | Dowel sleeve |

| 34 - | Input pinion |

| q | For front axle drive |

| q | Removing and installing → Chapter „Renewing oil seal in input pinion“ |

| 35 - | Intermediate pinion |

| q | For front axle drive |

| q | Installation position: gear identification faces towards transfer box |

| 36 - | Pinion gear |

| q | For front axle drive |

| q | Installation position: gear identification faces towards transfer box |

| 37 - | Oil seal |

| q | Renewing → Chapter |

|

|

|

|

|

|

|

|