| –

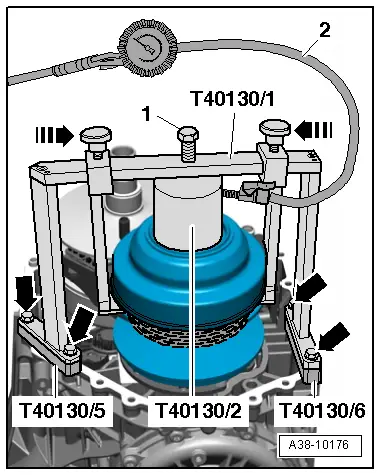

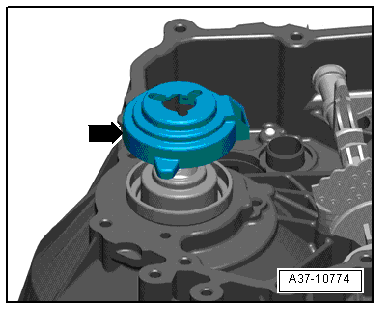

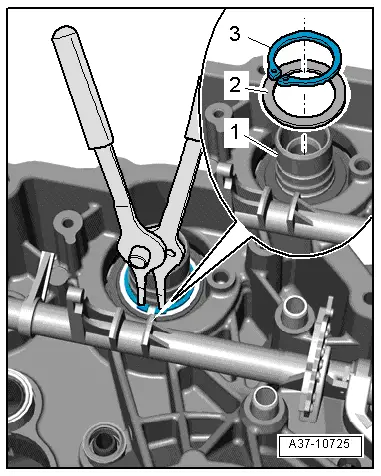

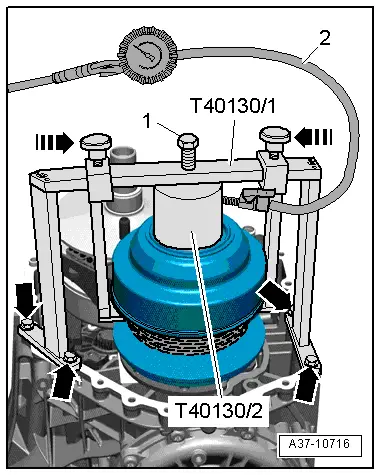

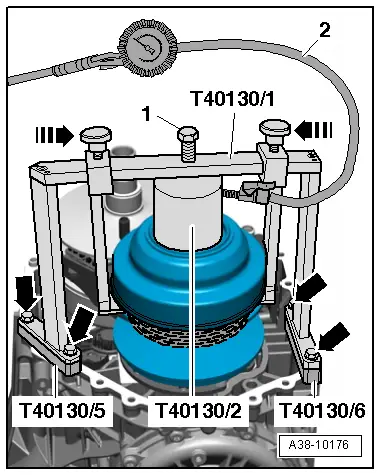

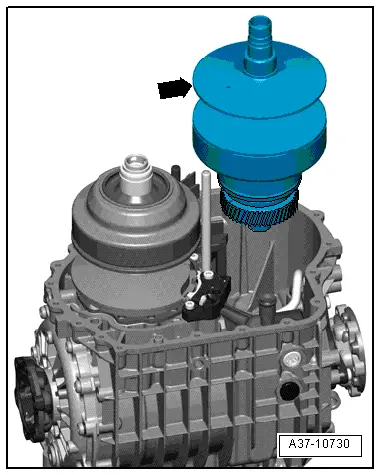

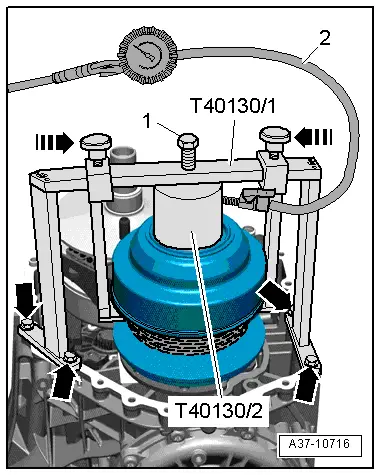

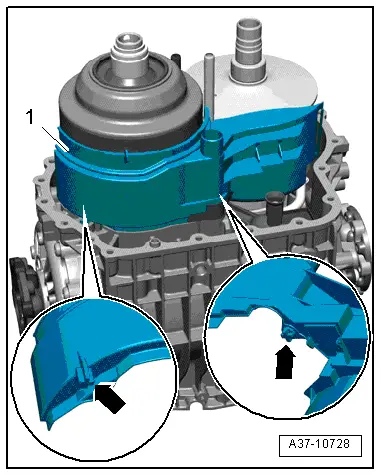

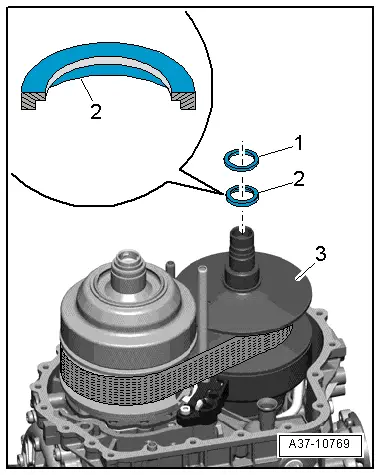

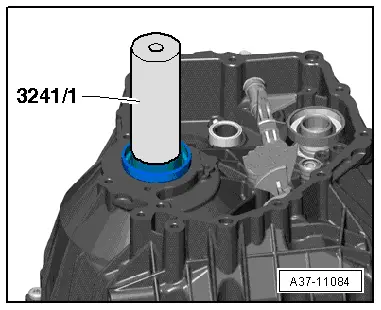

| Place adapter -T40130/2- on pulley set “II”. |

| l

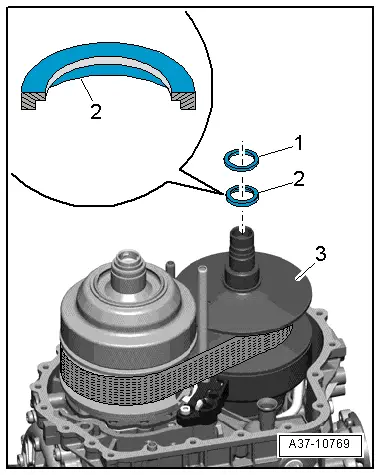

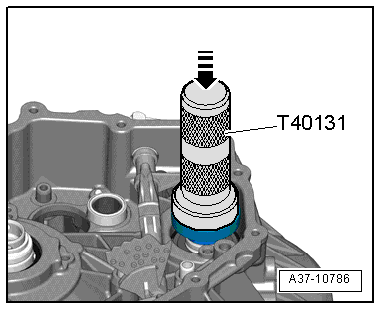

| Check for correct positioning of the O-rings in the adapter -T40130/2-. Both O-rings must be fitted. |

| l

| O-rings in adapter -T40130/2- and sealing surfaces on pulley set must be clean and coated with ATF. |

| –

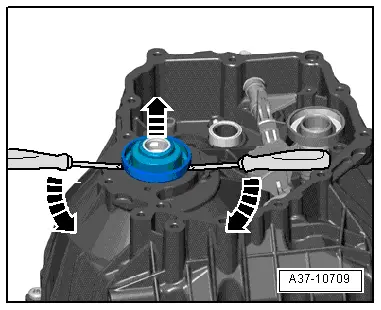

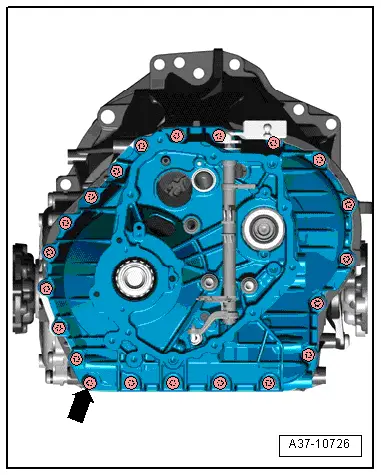

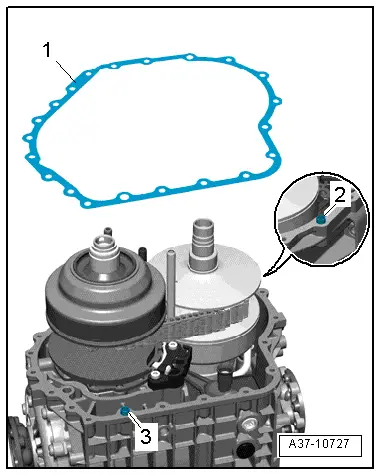

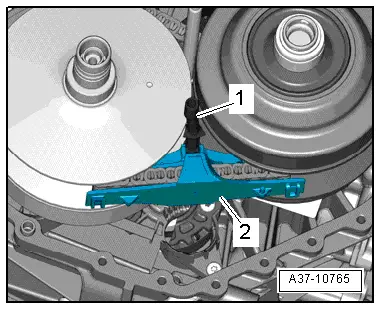

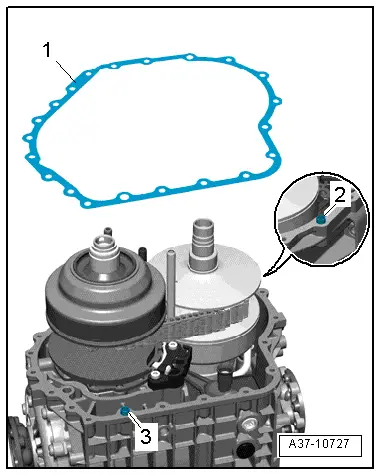

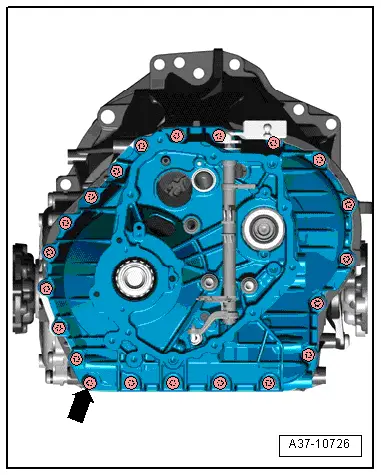

| Align support bracket -T40130/1- centrally on adapter -T40130/2- with spacers -T40130/5- and -T40130/6-, and bolt support bracket onto gearbox housing -bottom arrows-, as shown in illustration. |

| –

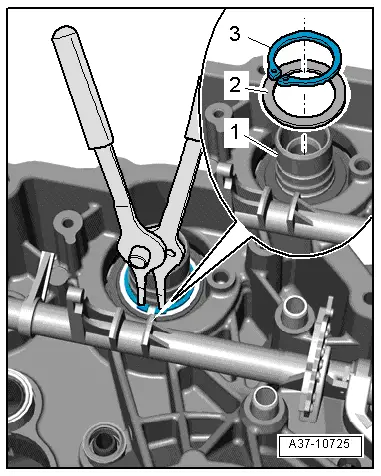

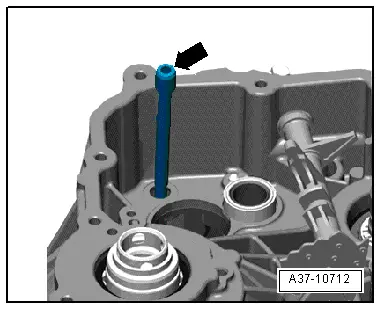

| Screw in bolt -1- until adapter -T40130/2- is pressed against pulley set “II”. |

| –

| Connect compressed air hose -2- for tyre valves to adapter -T40130/2- and apply approx. 3 bar. |

| l

| The pulley set should open and the chain should relax. |

| –

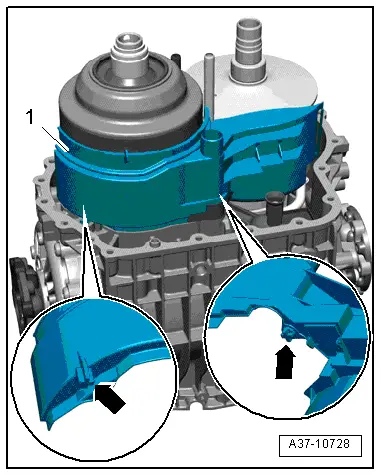

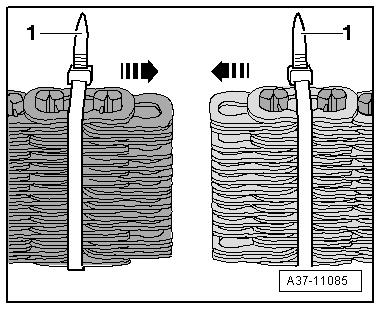

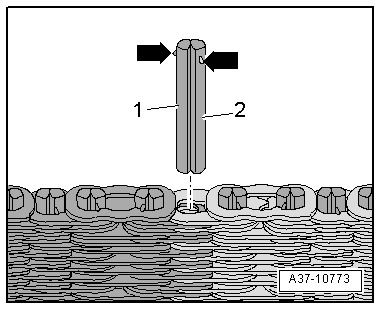

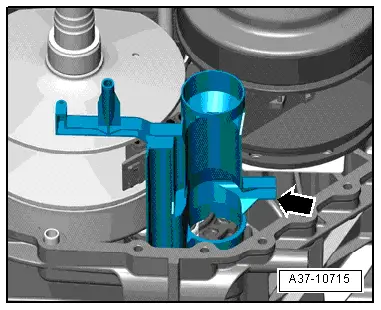

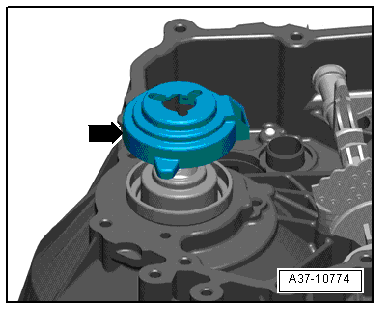

| Slide in the two arresters in the direction of the -arrows- to secure the top side of the pulley. |

| –

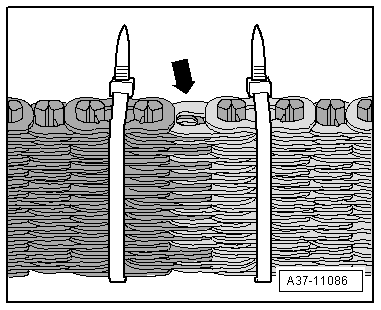

| Lock the arresters in this position using the knurled screws, taking care not to trap the chain. |

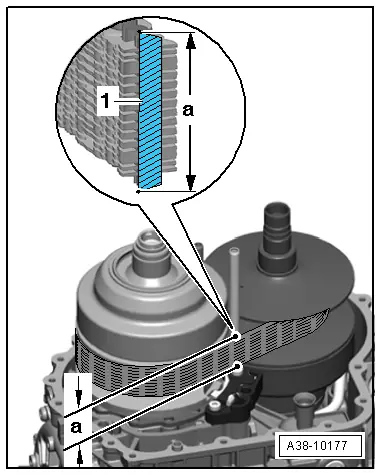

| Continued for gearboxes with any chain height: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution