A4 Mk2

| Renewing exhaust camshaft oil seal |

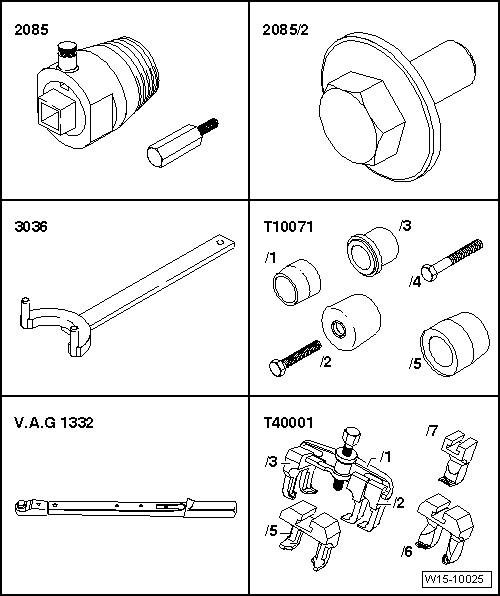

| Special tools and workshop equipment required |

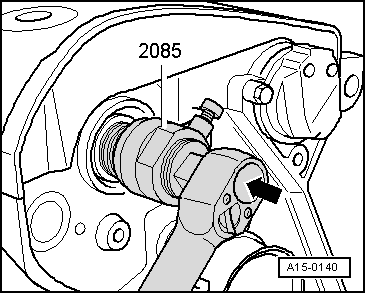

| t | Oil seal extractor -2085- |

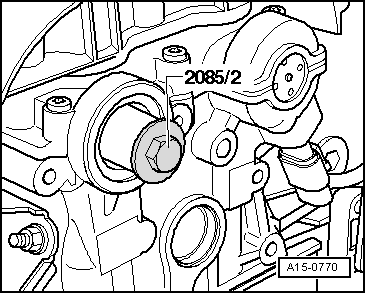

| t | Adapter -2085/2- |

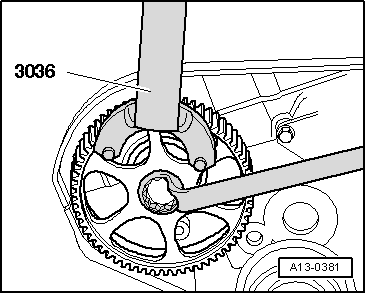

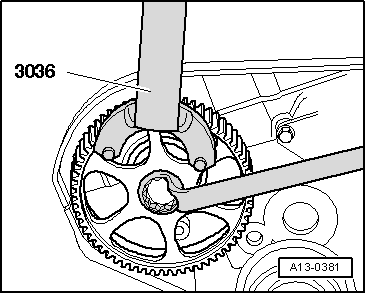

| t | Counterhold tool -3036- |

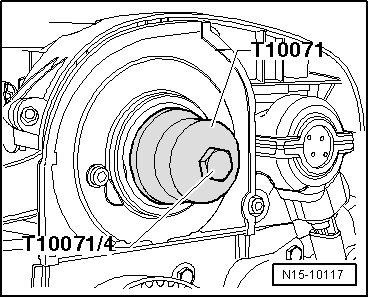

| t | Assembly tool -T10071- |

| t | Torque wrench -V.A.G 1332- |

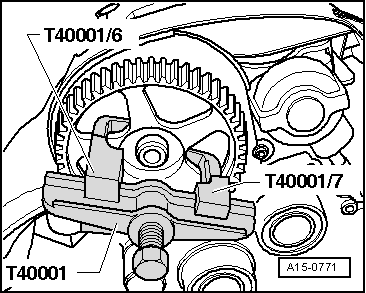

| t | Two-arm puller -T40001- with claw -T40001/6- and claw -T40001/7- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm | ||||

| Camshaft sprocket to camshaft | 50 + 90° 1)2) | ||||

| |||||