A4 Mk2

| Removing and installing sump and balance shaft assembly |

| Special tools and workshop equipment required |

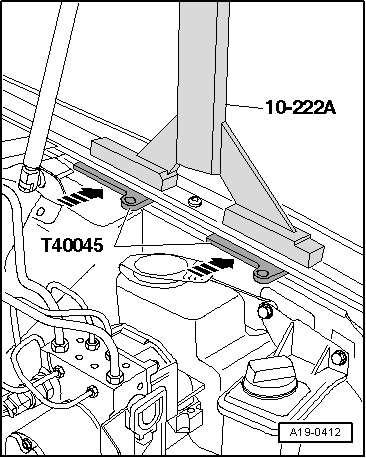

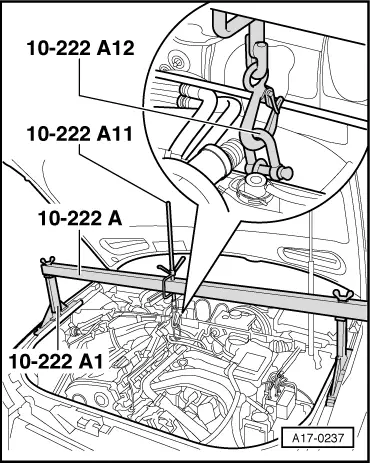

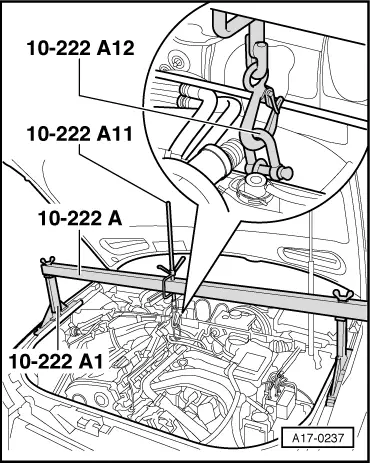

| t | Support bracket -10-222 A- |

| t | Shackle -10 - 222 A/12- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

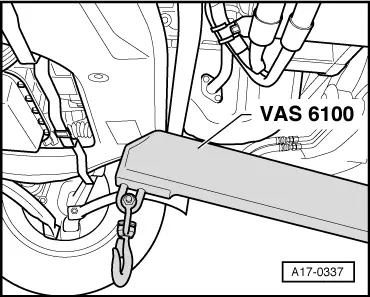

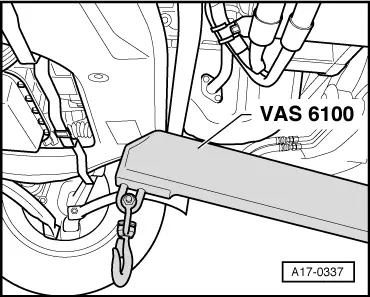

| t | Workshop hoist -VAS 6100- or workshop hoist -V.A.G 1202- |

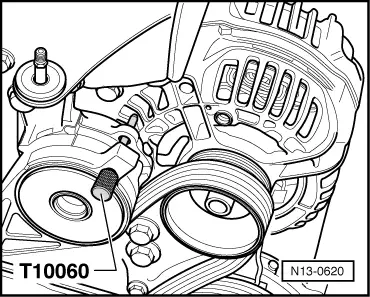

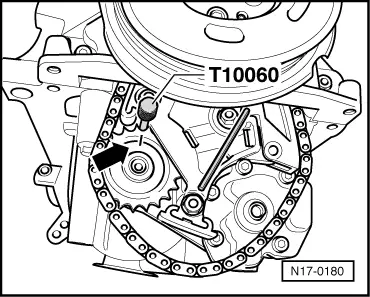

| t | Locking pin -T10060 A- or -T10060- |

| t | Mud wing compensation plate -T40045- |

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

| t | Sealant → Parts catalogue |

Note

Note

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

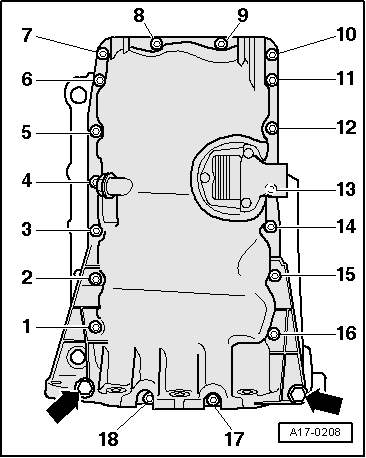

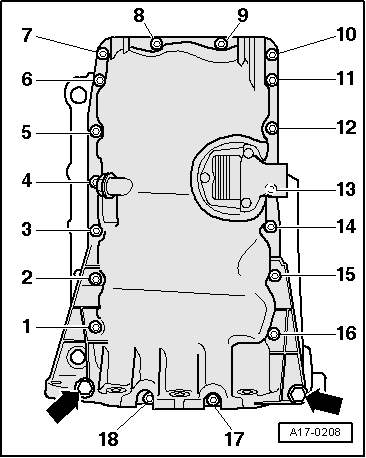

| Component | Nm | |||||

| Balance shaft assembly | 15 + 90° 1)2) | |||||

| Oil pump chain sprocket | 20 + 90° 1)2) | |||||

| Oil pipe to balance shaft assembly | 10 | |||||

| Sump to cylinder block | M7 | 15 | ||||

| M10 | 40 | |||||

| Sump to gearbox | 45 | |||||

| Intake manifold support to sump | 23 | |||||

| Torque reaction support to sump | 23 | |||||

| Oil drain plug | 30 | |||||

| Engine mounting to console for engine mounting | 23 | |||||

| ||||||

WARNING

WARNING Caution

Caution