A4 Mk2

|

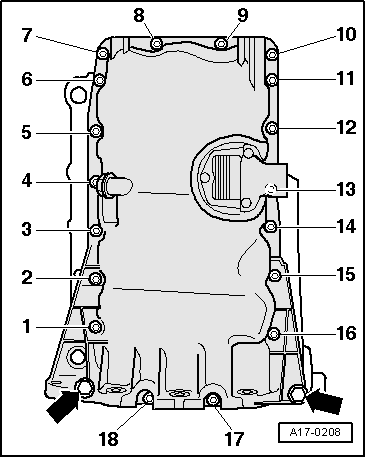

| 1 - | 15 Nm |

| 2 - | Oil dipstick |

| q | The oil level must not be above max. mark. |

| 3 - | Guide |

| 4 - | Guide tube |

| 5 - | Spacer plate |

| 6 - | Balance shaft assembly with oil pump |

| q | With pressure relief valve (12 bar) |

| q | Removing and installing → Chapter |

| 7 - | Bolt |

| q | Renew |

| q | Note different bolt lengths → Fig. |

| q | Tightening sequence → Fig. |

| 8 - | Bolt |

| q | Tightening sequence → Fig. |

| 9 - | Sump |

| q | Clean sealing surface before installing |

| q | Removing and installing → Chapter |

| 10 - | Bolt |

| q | Renew |

| q | Tightening sequence → Fig. |

| 11 - | Seal |

| q | Rolled onto → Item |

| 12 - | Oil drain plug, 30 Nm |

| q | With captive seal |

| q | Renew |

| 13 - | Chain sprocket |

| 14 - | 10 Nm |

| 15 - | Protective cap |

| 16 - | With oil level and oil temperature sender -G266- |

| 17 - | Seal |

| q | Renew |

| q | Lubricate before installing |

| 18 - | 20 Nm + turn 90° further |

| q | Renew |

| 19 - | Chain guard |

| 20 - | Chain |

| 21 - | Sealing flange |

| q | Must be positioned on dowel sleeves |

| q | Renewing crankshaft oil seal on pulley end → Chapter |