A4 Mk2

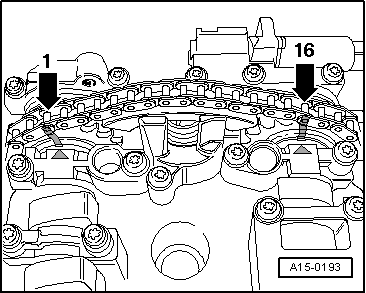

| Removing and installing camshafts and hydraulic chain tensioner |

| Special tools and workshop equipment required |

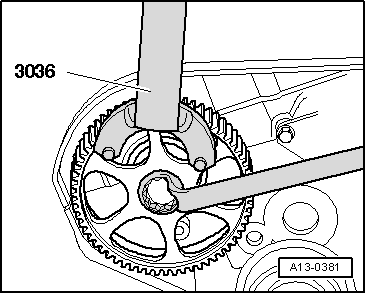

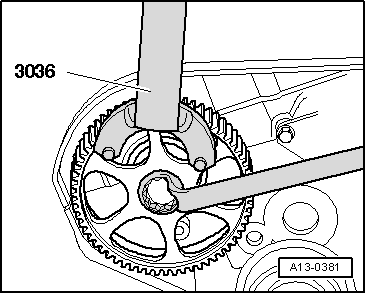

| t | Counterhold tool -3036- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

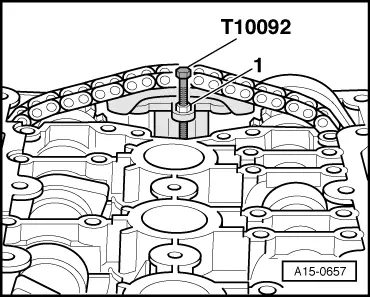

| t | Tensioning bolt -T10092- |

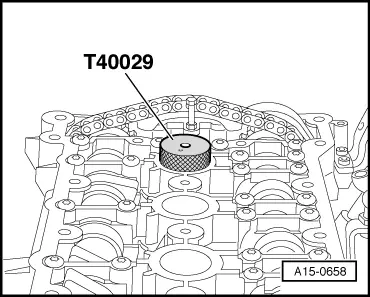

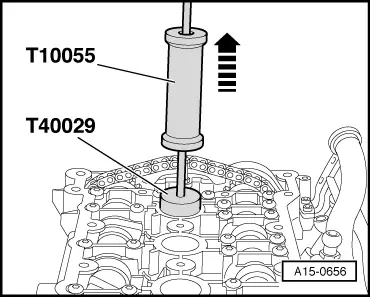

| t | Mandrel -T40029- |

| t | Puller -T10055- |

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

| t | Sealant → Parts catalogue |

Note

Note

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

| Component | Nm |

| Camshaft adjuster to camshaft | 100 |

| Hydraulic chain tensioner to cylinder head | 10 |

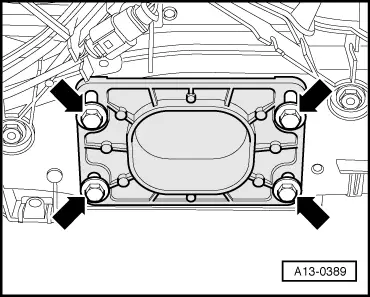

| Retaining frame to cylinder head | 8 |

| Camshaft sprocket to camshaft | 65 |

| Hall sender rotor to camshaft | 25 |

| Hall sender housing to cylinder head | 10 |

| Stop for torque reaction support to lock carrier | 28 |

WARNING

WARNING Caution

Caution