A4 Mk2

| Removing and installing sump |

| Special tools and workshop equipment required |

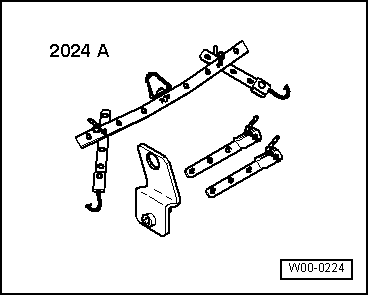

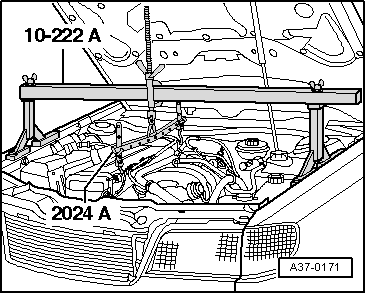

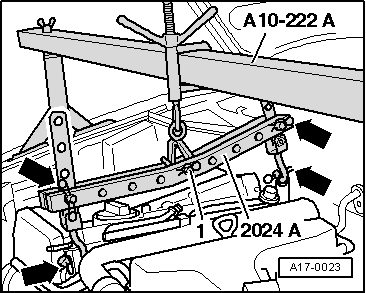

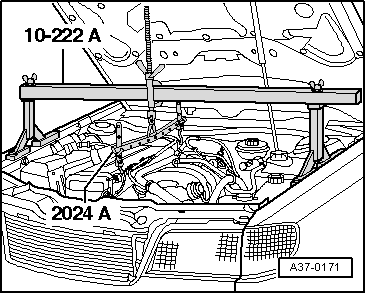

| t | Support bracket -10-222 A- |

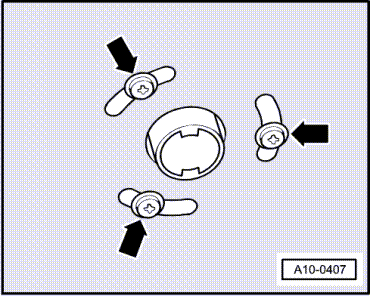

| t | Socket -3249- or -T10058- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

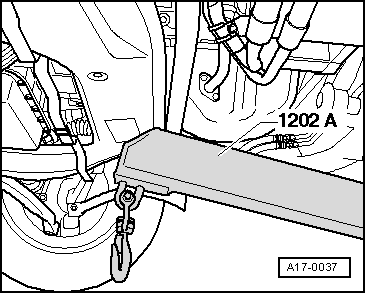

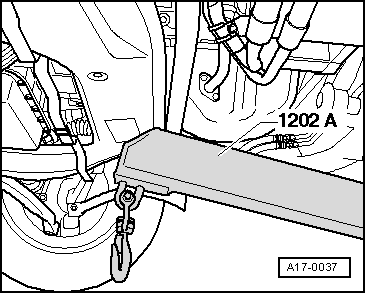

| t | Workshop crane -VAS 6100- or workshop crane -V.A.G 1202 A- |

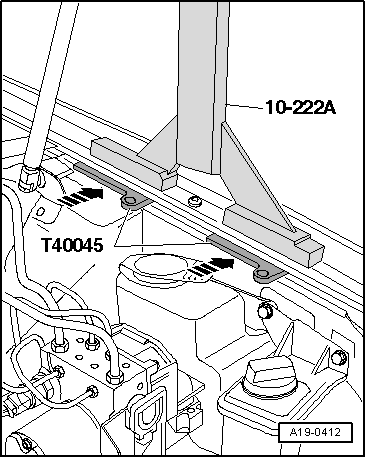

| t | Mud wing compensation plate -T40045- |

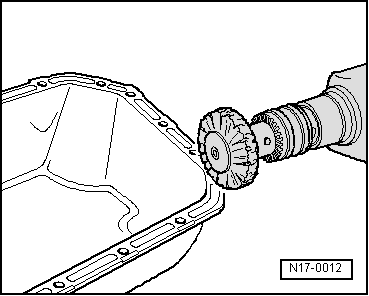

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

|

|

|

|

Note

Note

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

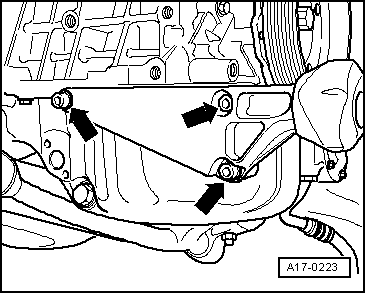

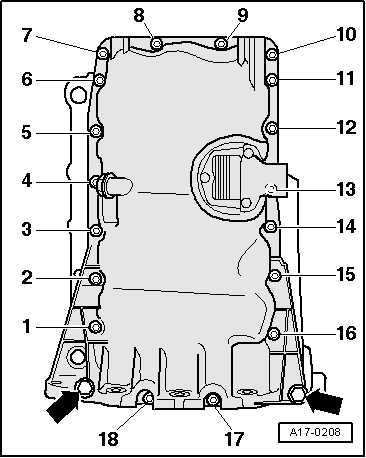

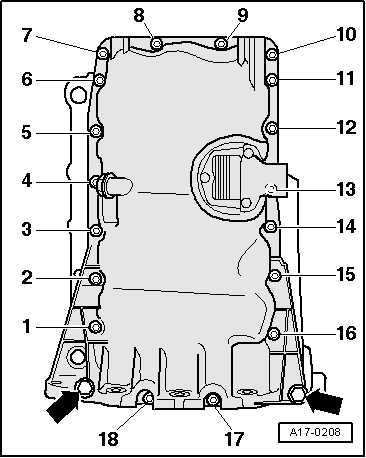

| Component | Nm | |

| Sump to | M7 | 15 |

| cylinder block | M10 | 40 |

| Sump to gearbox | 45 | |

| Oil return pipe to sump | 10 | |

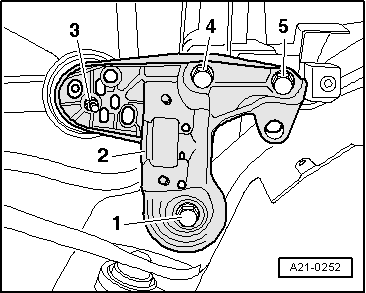

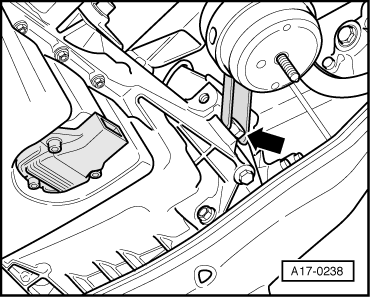

| Torque reaction support to sump | 23 | |

| Engine mounting to subframe | 23 | |

| Oil drain plug | 30 | |

WARNING

WARNING