| –

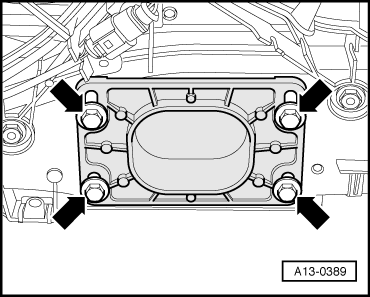

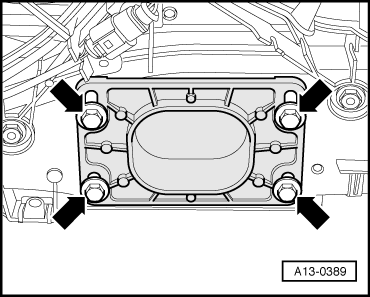

| Allow stop for torque reaction support to rest on rubber buffer for torque reaction support under its own weight and tighten bolts -arrows-. |

Caution | Do not use a battery charger to boost starting. There is danger of damaging the vehicle's control units. |

|

Note | t

| Drained-off coolant may only be used again if the original cylinder head and cylinder block are re-installed. |

| t

| Contaminated or dirty coolant must not be used again. |

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine oil or gearbox oil may be used, but do not use lubricant containing graphite. |

| t

| Do not use degreased parts. |

| t

| Tolerance for tightening torques: ± 15 %. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution