| –

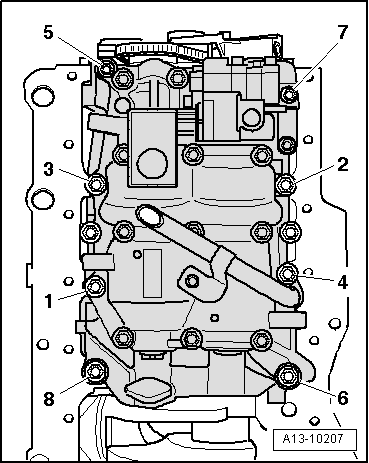

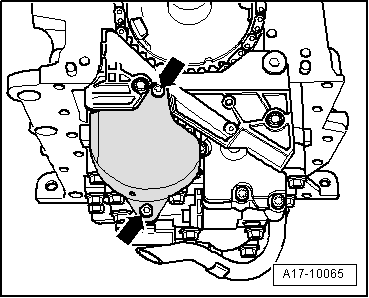

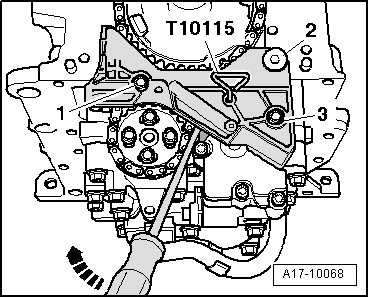

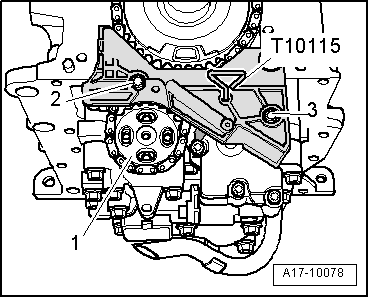

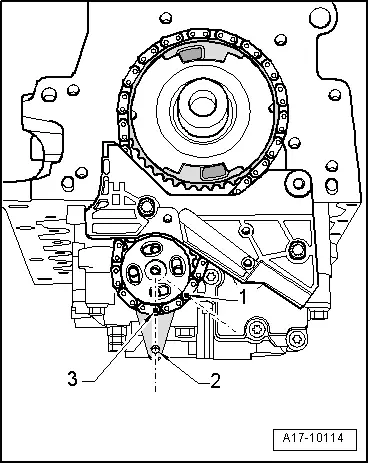

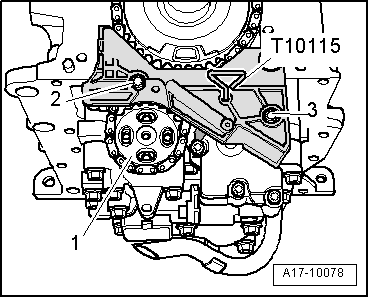

| Unscrew bolts in the sequence -8 ... 1- and remove balance shaft assembly with oil pump. |

Note | Renew the bolts tightened with specified tightening angle and the chain sprocket for balance shaft assembly. |

| l

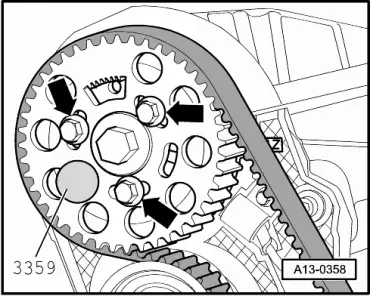

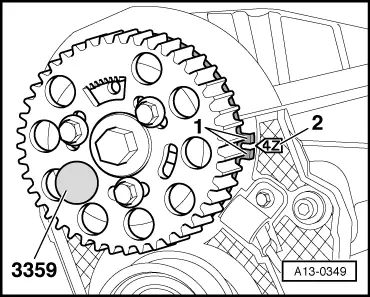

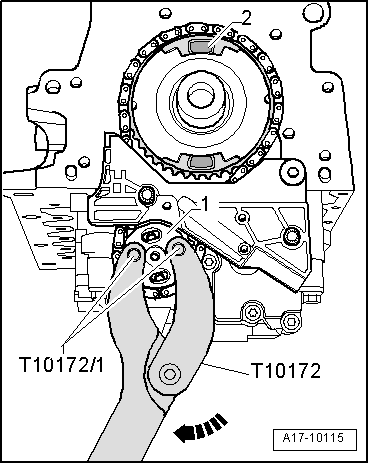

| Camshaft locked with locking pin -3359-. |

| –

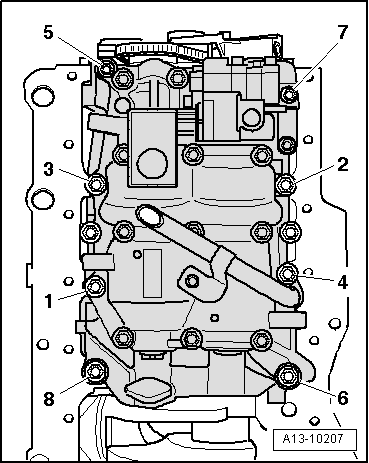

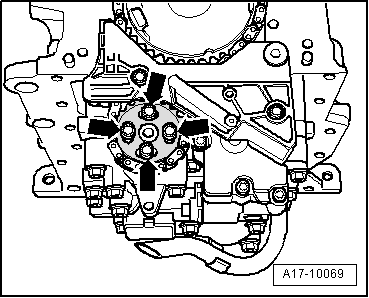

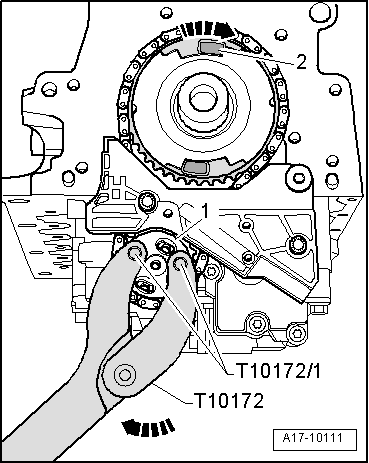

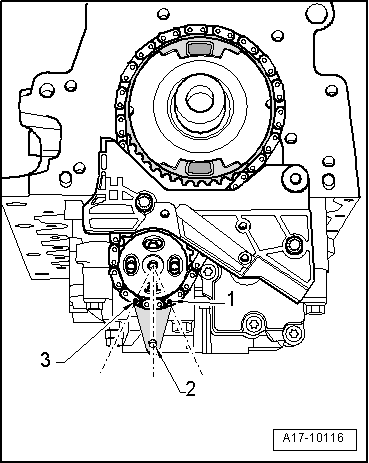

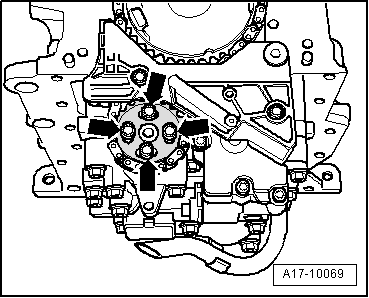

| Tighten bolts securing balance shaft assembly as follows: |

| 1.

| Pre-tighten bolts in the sequence -1 ... 8- to 6 Nm. |

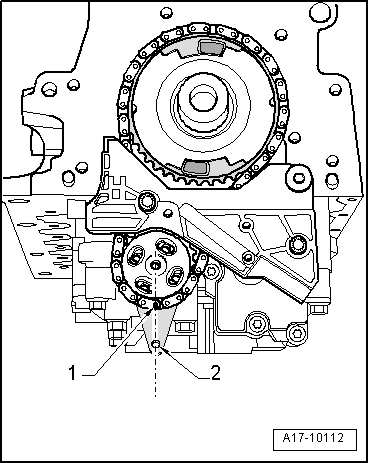

| 2.

| Tighten bolts -5- and -7- to 13 Nm. |

| 3.

| Turn bolts -5- and -7- 90° further using a rigid wrench. |

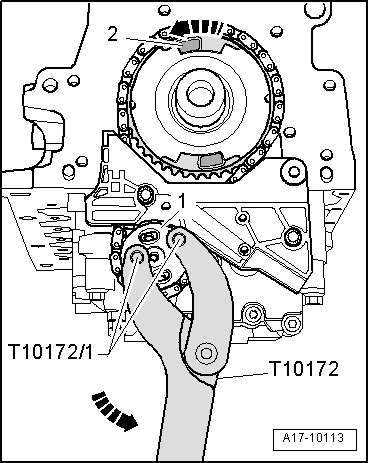

| 4.

| Tighten bolts -1 … 4-, -6- and -8- to 20 Nm. |

| 5.

| Turn bolts -1 ... 4-, -6- and -8- 90° further using a rigid wrench. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note