A4 Mk2

| Renewing camshaft oil seals |

| Special tools and workshop equipment required |

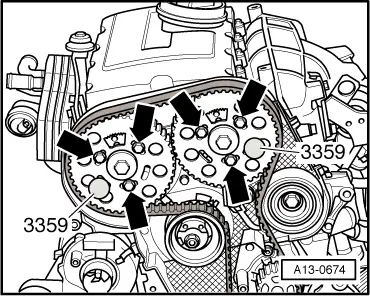

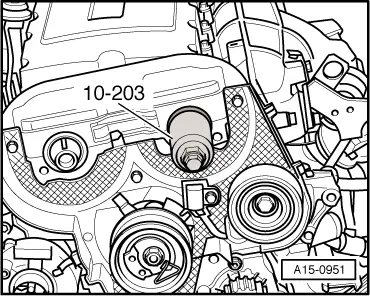

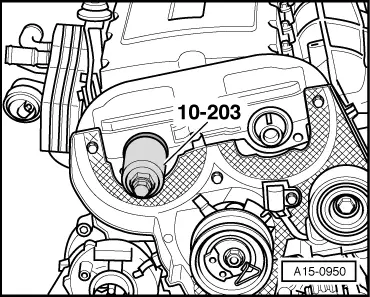

| t | Fitting tool -10-203- |

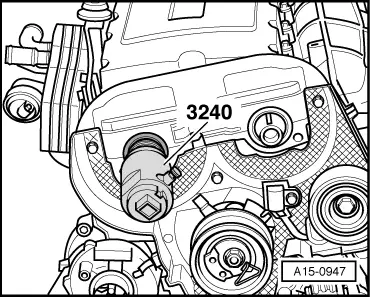

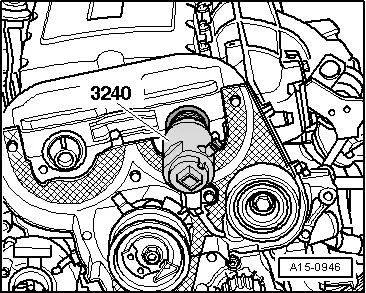

| t | Oil seal extractor -3240- |

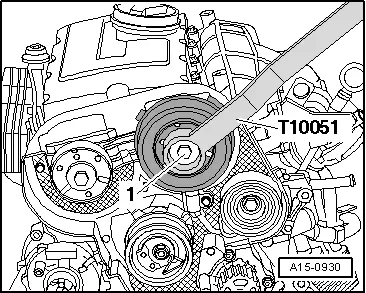

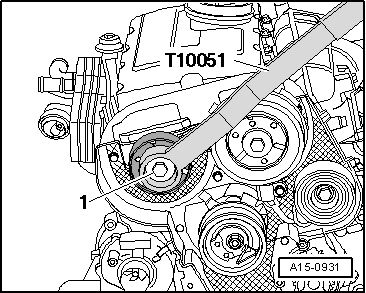

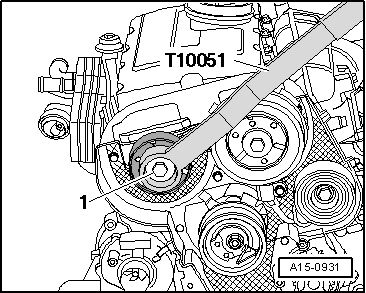

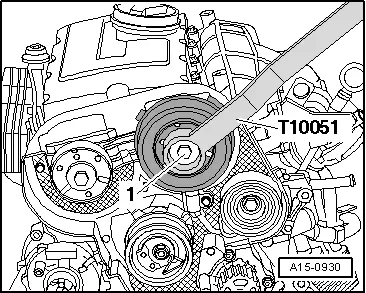

| t | Counterhold tool -T10051- |

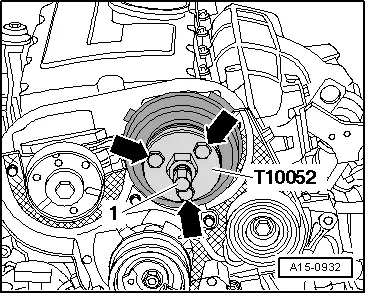

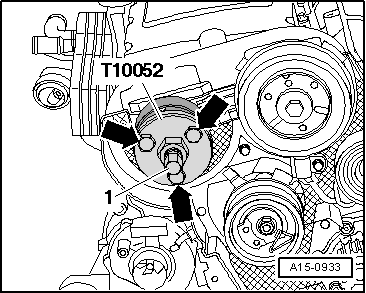

| t | Puller -T10052- |

| t | Bolt M12x60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Component | Nm |

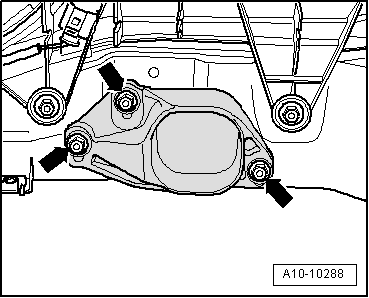

| Stop for torque reaction support to lock carrier | 28 |

| Hose clips (9 mm wide) | 3 |

| Hose clips (13 mm wide) | 5.5 |

Note

Note