A4 Mk2

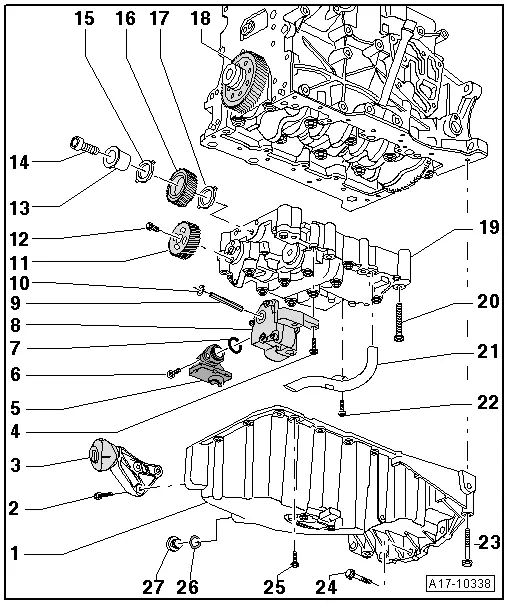

| Sump, oil pump, balance shaft assembly with spur gear drive - exploded view |

| 1 - | Sump |

| q | With oil level and oil temperature sender -G266- |

| q | Removing and installing sump → Chapter |

| 2 - | 23 Nm |

| 3 - | Torque reaction support |

| 4 - | 10 Nm |

| 5 - | Intake connecting pipe |

| q | Clean strainer if dirty |

| 6 - | 10 Nm |

| 7 - | O-ring |

| q | Renew |

| 8 - | Oil pump |

| q | Removing and installing → Chapter |

| q | Before installing, check that the two dowel sleeves for centring oil pump are fitted onto balance shaft assembly. |

| 9 - | Oil pump drive shaft |

| 10 - | Circlip |

| q | Must fit securely in groove |

| q | Renew circlip if damaged or stretched |

| 11 - | Spur gear for balance shaft |

| 12 - | 20 Nm + turn 90° further |

| q | Renew |

| 13 - | Hub |

| q | For idler gear |

| 14 - | 90 Nm + turn 90° further |

| q | Renew |

| 15 - | Thrust washer |

| q | For idler gear |

| q | Renew |

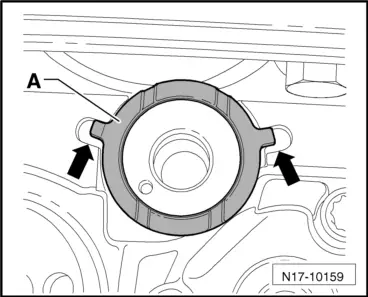

| q | Installation position → Fig. |

| 16 - | Idler gear |

| q | Renew |

| q | To achieve the correct backlash a suitably thick coating is already applied to the new idler gear |

| q | Installing → Chapter |

| 17 - | Thrust washer |

| q | For idler gear |

| 18 - | Spur gear |

| 19 - | Balance shaft assembly |

| q | Removing → Chapter |

| q | Installing new balance shaft assembly → Chapter |

| q | Re-installing "old" balance shaft assembly → Chapter |

| q | Before installing, check that the two dowel sleeves for centring balance shaft assembly are fitted onto cylinder block. |

| 20 - | Bolt |

| q | Renew |

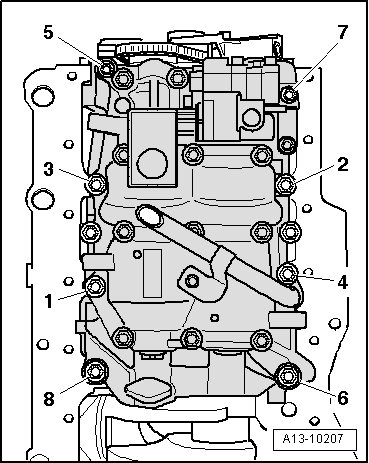

| q | Tightening torque and sequence with eight attachment points → Fig. |

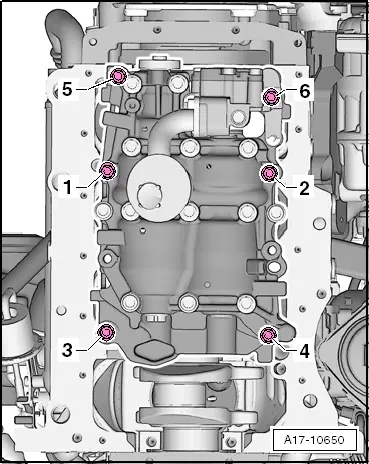

| q | Tightening torque and sequence with six attachment points → Fig. |

| 21 - | Oil intake pipe |

| 22 - | 10 Nm |

| 23 - | 40 Nm |

| q | Observe correct tightening sequence → Anchor |

| 24 - | 45 Nm |

| q | Observe correct tightening sequence → Anchor |

| 25 - | 15 Nm |

| q | Tighten in stages and in diagonal sequence |

| q | Observe correct tightening sequence → Anchor |

| 26 - | Seal |

| q | Renew |

| 27 - | Oil drain plug, 30 Nm |

|

|

| Stage | Bolts | Tightening torque/angle specification |

| 1. | -1 … 8- | hand-tighten |

| 2. | -1 … 8- | 6 Nm |

| 3. | -1 … 4- | 20 Nm |

| 4. | -5- | 13 Nm |

| 5. | -6- | 20 Nm |

| 6. | -7- | 13 Nm |

| 7. | -8- | 20 Nm |

| 8. | -1 … 8- | turn 90° further |

|

|

| Stage | Bolts | Tightening torque/angle specification |

| 1. | -1 … 6- | hand-tighten |

| 2. | -1 … 6- | 6 Nm |

| 3. | -1 … 4- | 20 Nm |

| 4. | -5, 6- | 13 Nm |

| 5. | -1 … 6- | turn 90° further |

Caution

Caution