A4 Mk2

| Removing engine |

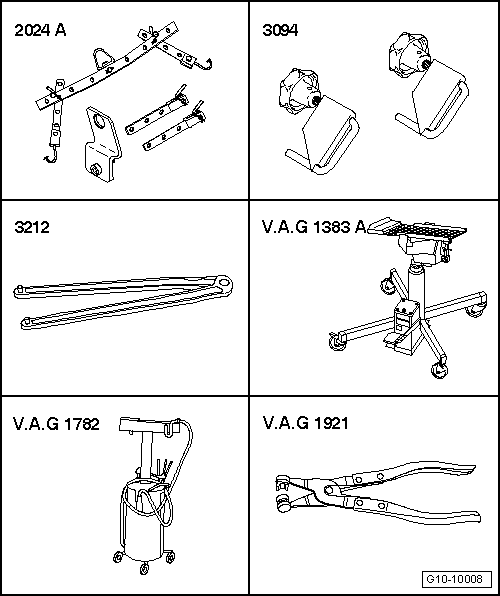

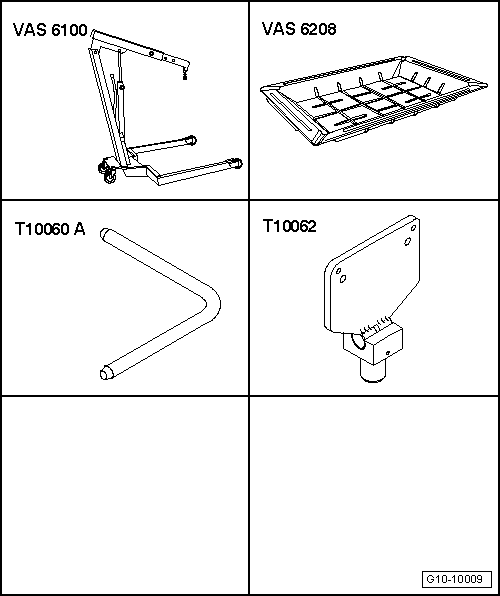

| Special tools and workshop equipment required |

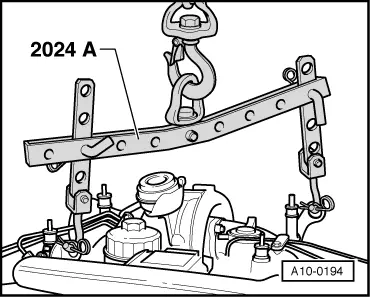

| t | Lifting tackle -2024 A- |

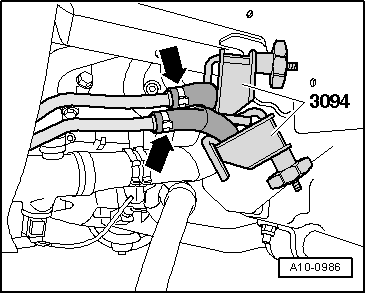

| t | Hose clamps for hoses up to 25 mm Ø -3094- |

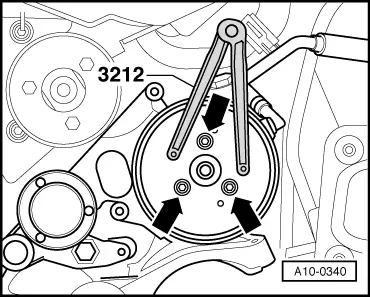

| t | Pin wrench -3212- |

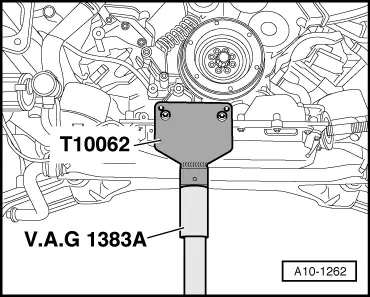

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Hose clip pliers -V.A.G 1921- |

| t | Workshop hoist -VAS 6100- or workshop hoist -V.A.G 1202 A- |

| t | Drip tray for workshop hoist -VAS 6208- or drip tray -V.A.G 1306- |

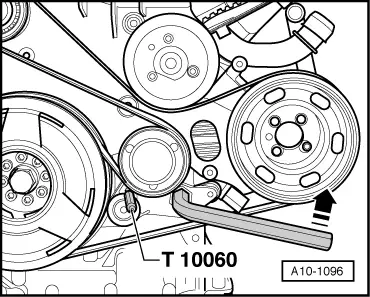

| t | Locking pin -T10060- or -T10060 A- |

| t | Support -T10062- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

Note

Note

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING