A4 Mk2

| Removing, installing and checking thermostat |

| Special tools and workshop equipment required |

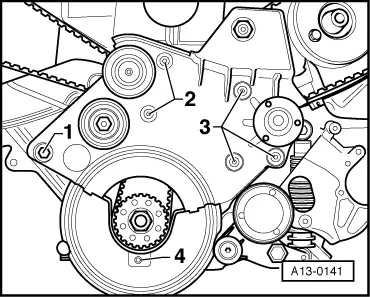

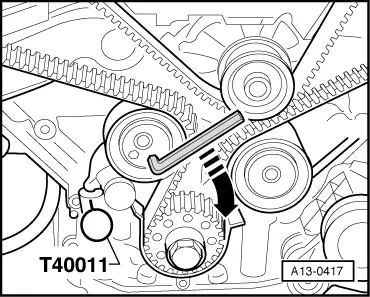

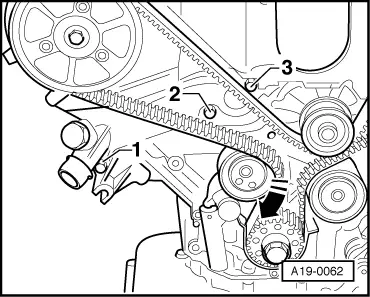

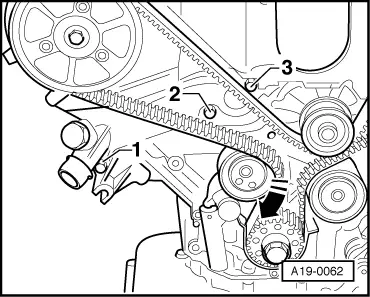

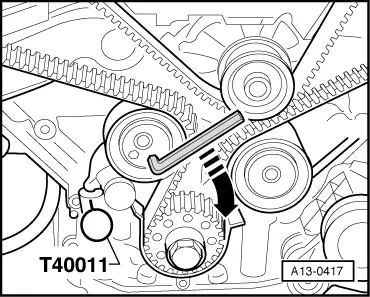

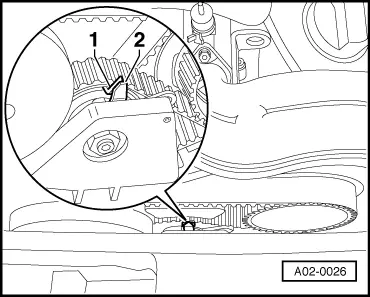

| t | Locking pin -T40011- |

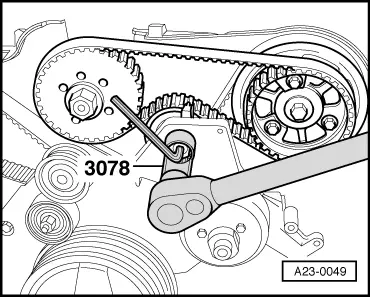

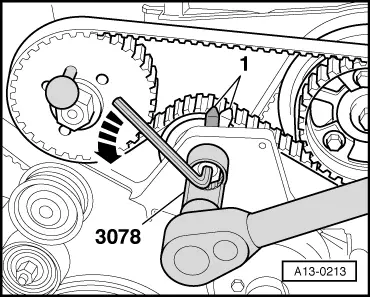

| t | Socket (22 mm) -3078- |

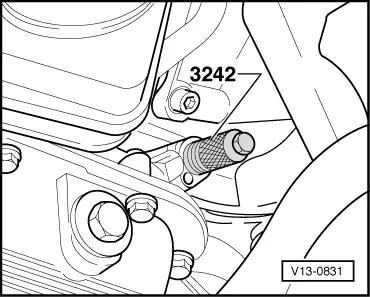

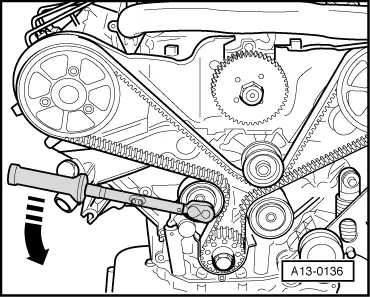

| t | Locking pin -3242- |

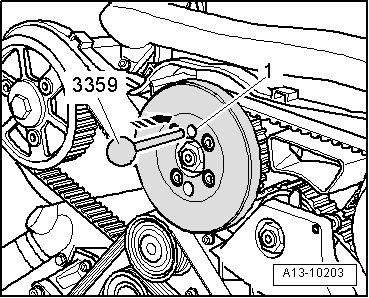

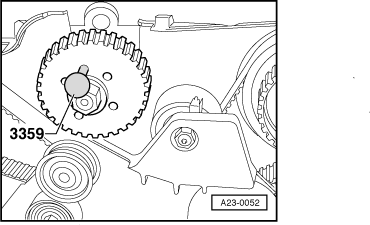

| t | Diesel injection pump locking pin -3359- |

| t | Locking fluid → Parts catalogue |

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

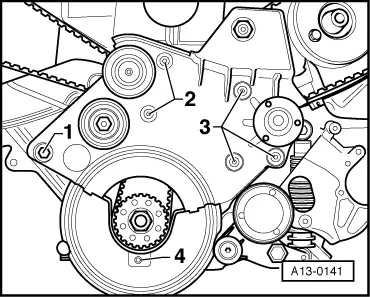

| Component | Nm | ||

| Thermostat housing to cylinder block | 10 → Note | ||

| Viscous fan pulley to hub | 10 | ||

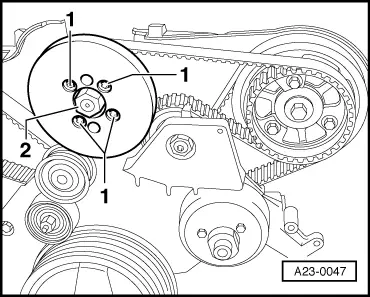

| Tensioning roller for injection-pump toothed belt to bracket for viscous fan | 36 | ||

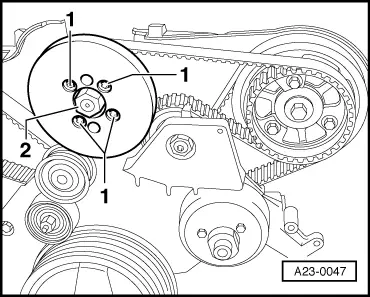

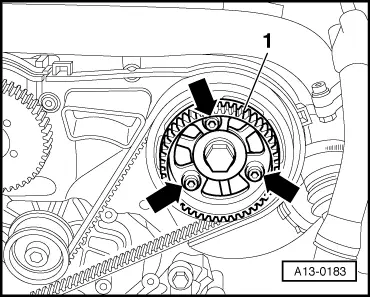

| Drive sprocket for injection pump to camshaft | 22 | ||

| Screw plug in cylinder block | M6 | 10 | |

| M18 | 35 | ||

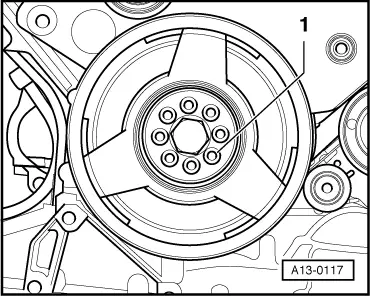

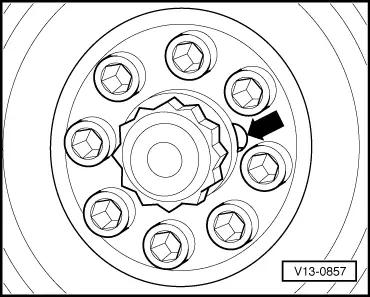

| Vibration damper to injection pump sprocket | 22 | ||

| Toothed belt cover (rear) to | Cylinder head | 10 | |

| Injection pump | 10 | ||

| Vibration damper to crankshaft sprocket | 22 | ||

|

| Starts to open | Fully open | Opening travel |

| approx. 87 °C | approx. 102 °C → Note | at least 8 mm |

|

Caution

Caution WARNING

WARNING