| Checking hydraulic valve compensation elements |

| Special tools and workshop equipment required |

Note | t

| Hydraulic valve compensation elements cannot be serviced. |

| t

| Irregular valve noises when starting engine are normal. |

| –

| Start engine and run until coolant temperature reaches approx. 80 °C. |

| –

| Increase engine speed to approx. 2500 rpm for 2 minutes (perform road test if necessary). |

Note | t

| If irregular valve noise disappears but repeatedly re-occurs when travelling short distances, renew oil retention valves. |

| t

| The oil retention valves are located below the oil filter bracket → Chapter. |

| If the hydraulic valve compensation elements are still noisy, locate the defective element as follows: |

| –

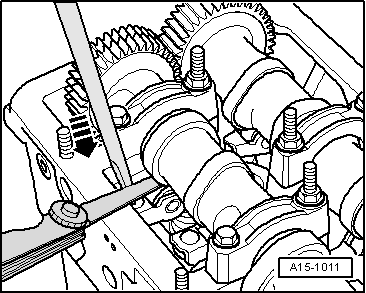

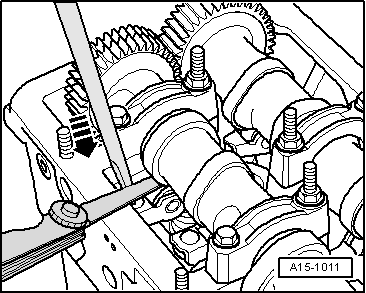

| Rotate crankshaft until cam of hydraulic compensation element to be checked faces upwards. The procedure is: |

| t

| Vehicles with manual gearbox: push vehicle forwards with 4th gear engaged and ignition switched off. |

| t

| Vehicles with automatic gearbox: rotate crankshaft in clockwise direction via central bolt for vibration damper. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note