| –

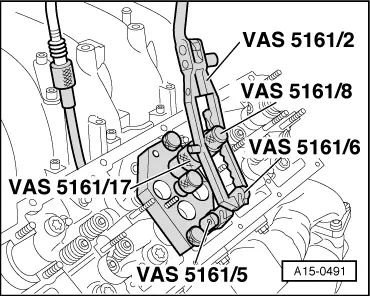

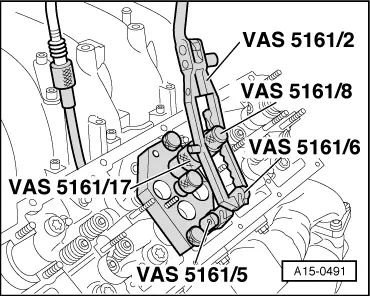

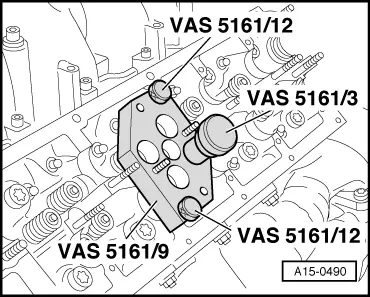

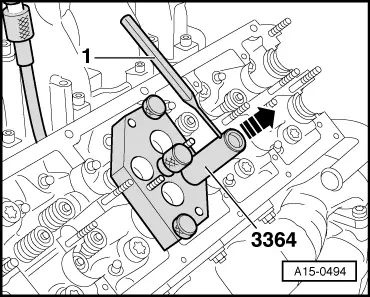

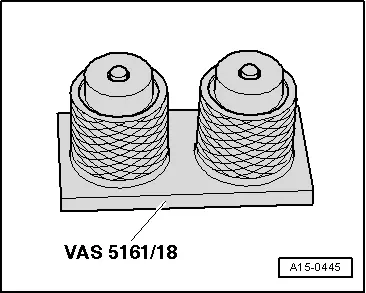

| Re-insert assembly cartridge into guide plate -VAS 5161/9-. |

| –

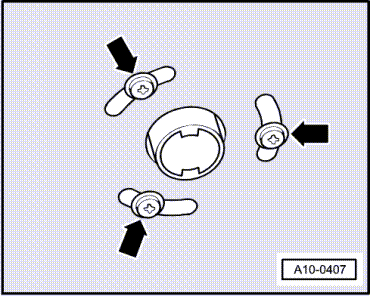

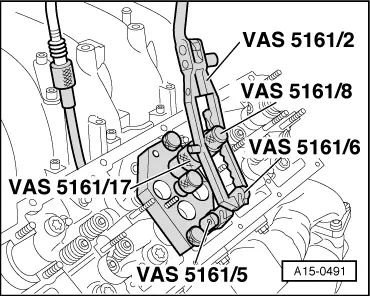

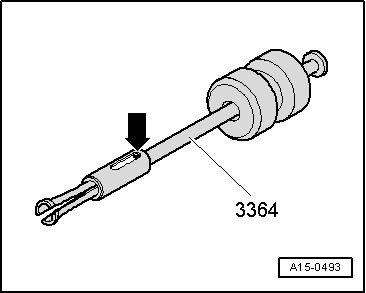

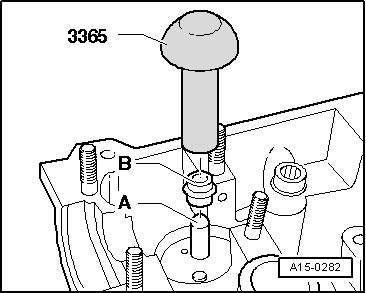

| Push pressure fork down and pull knurled screw upwards, while turning screw in both directions – this will insert the valve cotters. |

| –

| Release the pressure fork with knurled screw still in pulled position. |

| –

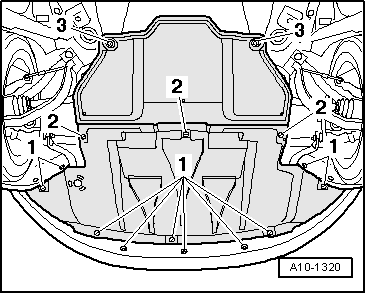

| Install toothed belt (adjust valve timing) → Anchor. |

Note | t

| After installing camshafts, wait for approx. 30 minutes before starting engine. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

|

|

Note

Note Note

Note

Note

Note