A4 Mk2

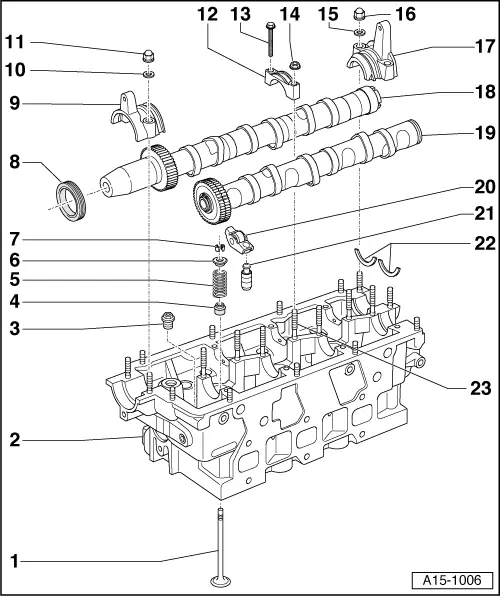

| Valve gear - exploded view of components |

Note

Note| t | After installing camshafts, wait for approx. 30 minutes before starting engine. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons). |

| t | After working on the valve gear, turn the engine carefully at least 2 rotations by hand to ensure that none of the valves make contact when the starter is operated. |

| t | The following illustration shows the left-side cylinder head. |

| 1 - | Valve |

| q | Checking → Chapter |

| q | Valve dimensions → Chapter |

| q | Remove and install with cylinder head removed using valve spring compressor -2037- |

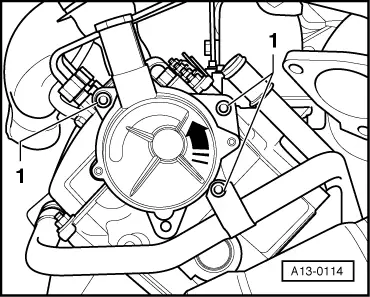

| 2 - | Cylinder head |

| q | Removing: left-side → Chapter; right-side → Chapter |

| q | Installing → Chapter |

| q | Do not machine valve seats |

| q | With exhauster pump for brake servo |

| q | Removing and installing exhauster pump → Fig. |

| 3 - | Pressure limiting valve |

| q | For lubricating points in cylinder head |

| q | Tighten to 25 Nm |

| 4 - | Valve stem oil seal |

| q | Renewing valve stem oil seals with cylinder head installed → Chapter |

| q | Renewing valve stem oil seals with cylinder head removed → Chapter |

| 5 - | Valve spring |

| 6 - | Valve spring plate |

| 7 - | Valve cotters |

| 8 - | Oil seal |

| q | Renewing → Chapter |

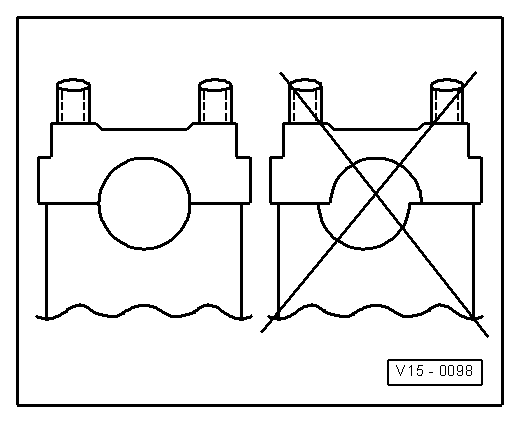

| 9 - | Camshaft bearing caps for inlet camshaft |

| q | Before fitting, apply sealant to sealing surfaces of outer bearing caps → Chapter |

| q | Installation sequence → Chapter |

| 10 - | Seal |

| q | Renew |

| 11 - | Cap nut, 15 Nm |

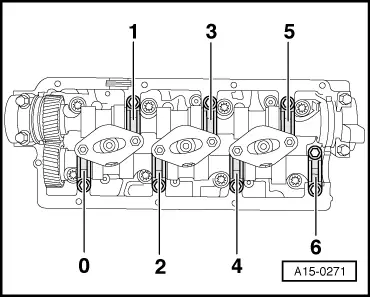

| 12 - | Camshaft bearing caps |

| q | Installation position → Fig. |

| q | Installation sequence → Chapter |

| 13 - | 10 Nm |

| 14 - | 10 Nm |

| 15 - | Seal |

| q | Renew |

| 16 - | Cap nut, 15 Nm |

| 17 - | Camshaft bearing caps for inlet camshaft |

| q | Before fitting, apply sealant to sealing surfaces of outer bearing caps → Chapter |

| q | Installation sequence → Chapter |

| 18 - | Inlet camshaft |

| q | Removing and installing → Chapter |

| q | Checking axial clearance → Chapter |

| q | Check radial clearance with Plastigage (roller rocker fingers removed) |

| q | Radial clearance when new: 0.035 ... 0.085 mm; Wear limit 0.10 mm |

| q | Runout: max. 0.04 mm |

| 19 - | Exhaust camshaft |

| q | Removing and installing → Chapter |

| q | Checking axial clearance → Chapter |

| q | Check radial clearance with Plastigage (roller rocker fingers removed) |

| q | Radial clearance when new: 0.035 ... 0.085 mm; Wear limit 0.10 mm |

| q | Runout: max. 0.04 mm |

| 20 - | Roller rocker finger |

| q | Mark installation position with a coloured pen |

| 21 - | Hydraulic valve compensation element |

| q | Mark installation position with a coloured pen |

| q | Checking → Chapter |

| q | Lubricate contact surface before fitting |

| 22 - | Thrust washers |

| q | 2x |

| 23 - | Stud |

| q | For bearing cap |

| q | Secure only hand-tight |

|

|

|

|

|

|