A4 Mk2

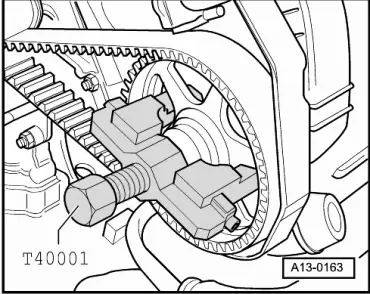

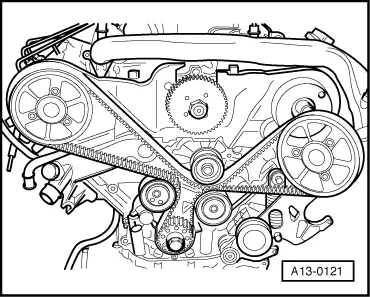

| Removing toothed belt from camshaft sprockets |

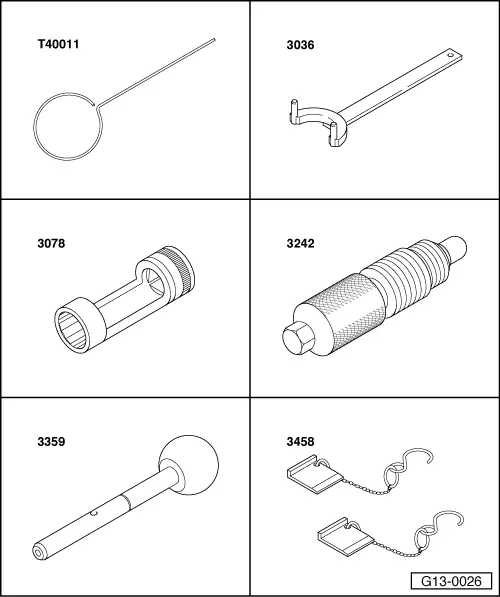

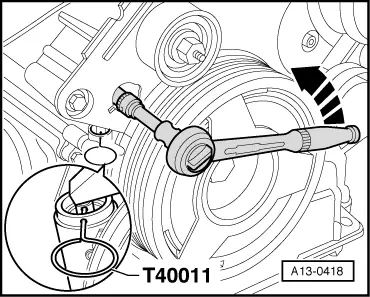

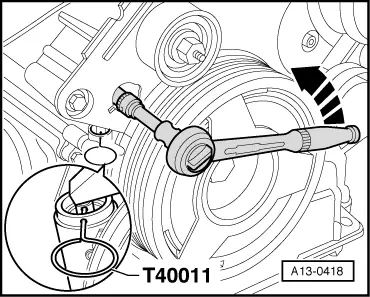

| t | Locking pin -T40011- |

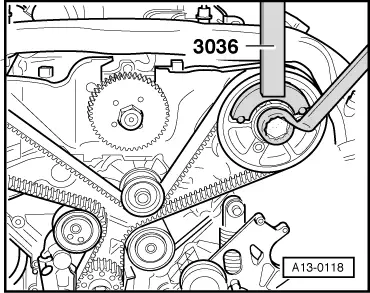

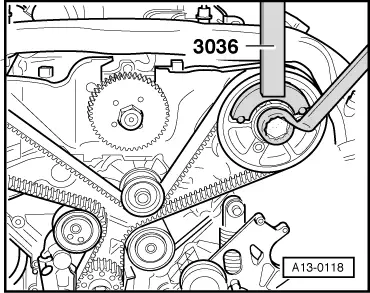

| t | Counterhold tool -3036- |

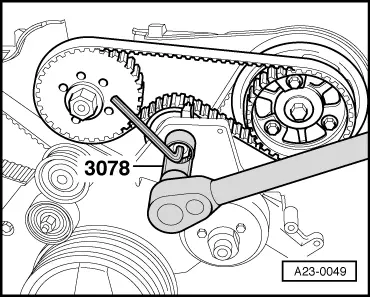

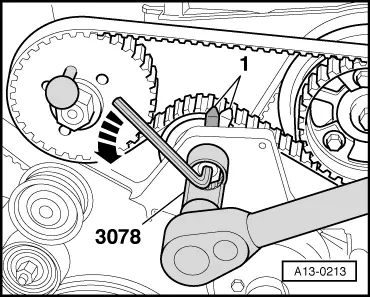

| t | Socket (22 mm) -3078- |

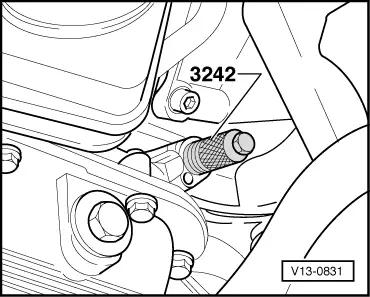

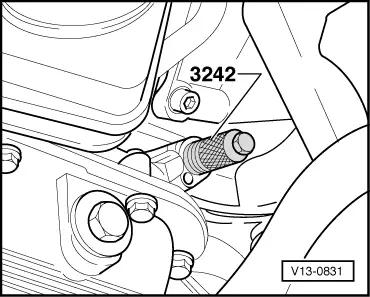

| t | Locking pin -3242- |

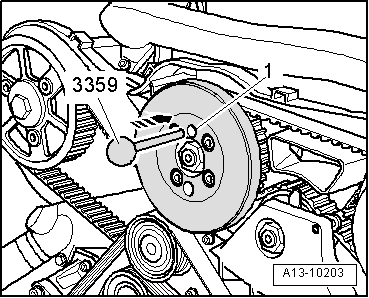

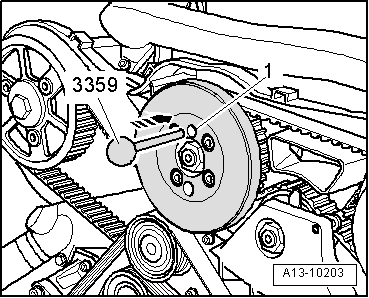

| t | Diesel injection pump locking pin -3359- |

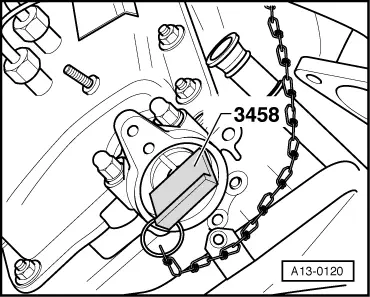

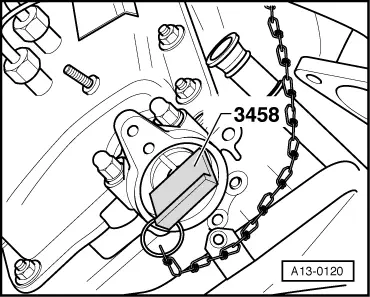

| t | Camshaft clamp -3458- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

| Component | Nm |

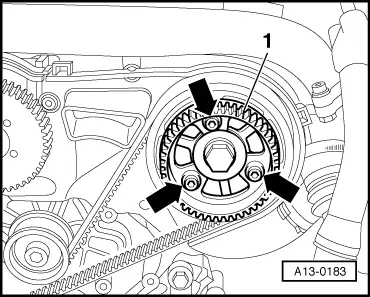

| Camshaft sprocket to camshaft | 75 |

| Drive sprocket for injection pump to camshaft | 22 |

| Tensioning roller for injection-pump toothed belt to bracket for viscous fan | 36 |

| Exhauster pump to cylinder head | 10 |

| Screw plug in cylinder block | 35 |

| Hose clips (9 mm wide) | 3 |

| Hose clips (13 mm wide) | 5.5 |

Caution

Caution WARNING

WARNING