A4 Mk2

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

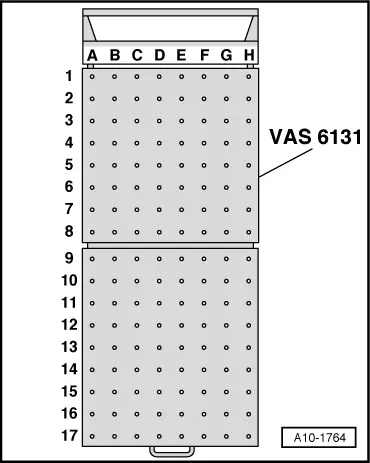

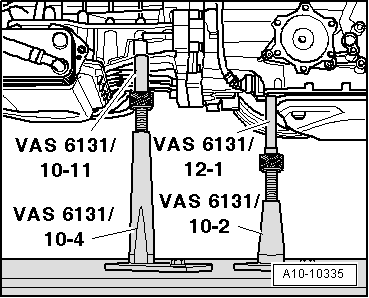

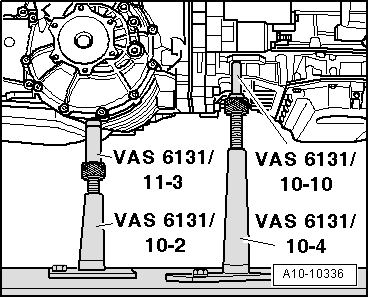

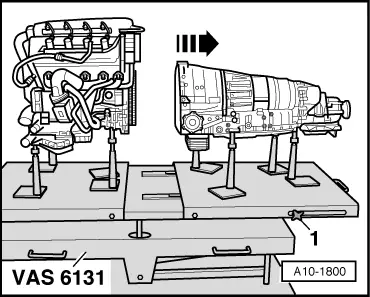

| Platform coordinates | Parts of support set for Audi -VAS 6131/10-, -VAS 6131/11- and -VAS 6131/12- | |||||

| B4 1) | /10-1 | /10-4 | /10-5 | /10-11 | ||

| G4 1) | /10-1 | /10-4 | /10-5 | /10-12 | ||

| B7 | /10-1 | /10-4 | /10-5 | /10-11 | ||

| G7 | /10-1 | /10-4 | /10-5 | /10-10 | ||

| B10 | /10-1 | /10-2 | /10-5 | /12-1 | ||

| G10 | /10-1 | /10-2 | /10-5 | /11-3 | ||

| D15 1) | /10-1 | /10-3 | /10-5 | /10-12 | ||

| F15 1) | /10-1 | /10-3 | /10-5 | /10-12 | ||

| ||||||

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note |

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|