A4 Mk2

| Detaching timing chains from camshafts, removing and installing chain tensioners |

| Special tools and workshop equipment required |

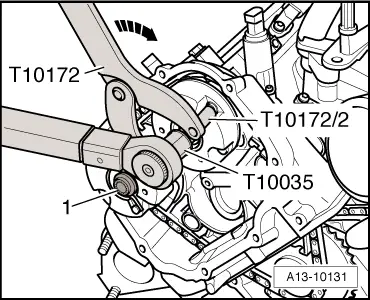

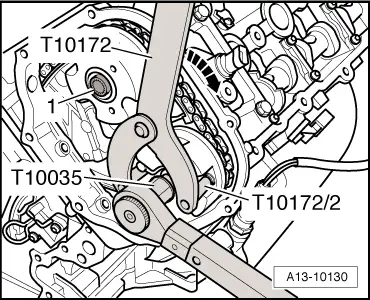

| t | Counterhold tool -T10172- with pin -T10172/2- |

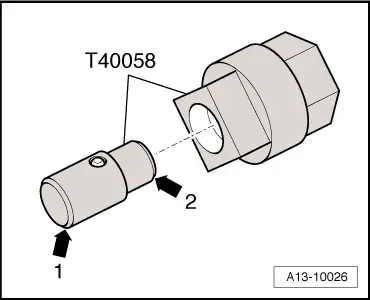

| t | Adapter -T40058- |

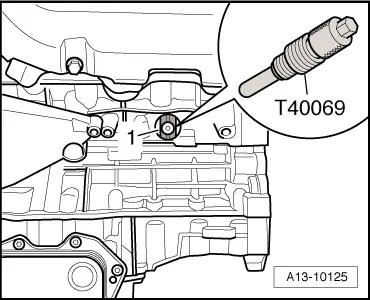

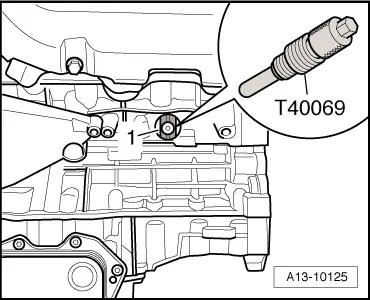

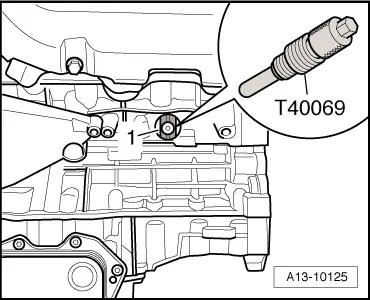

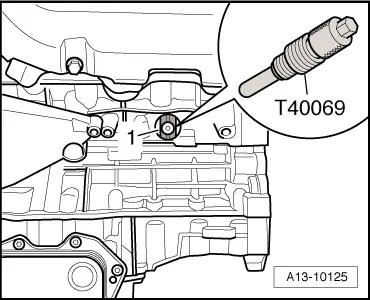

| t | Locking pin -T40069- |

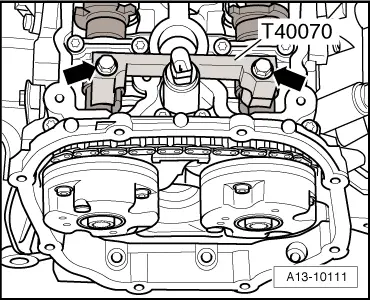

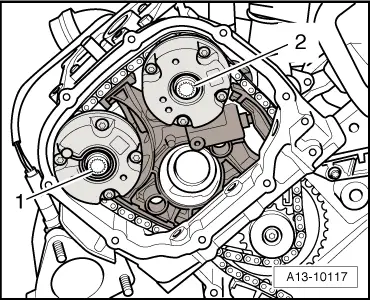

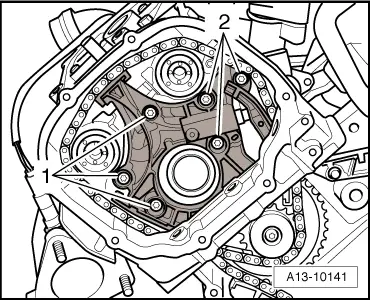

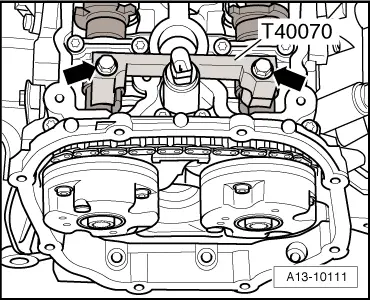

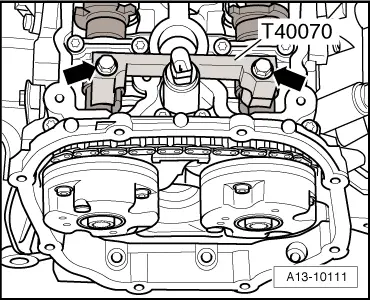

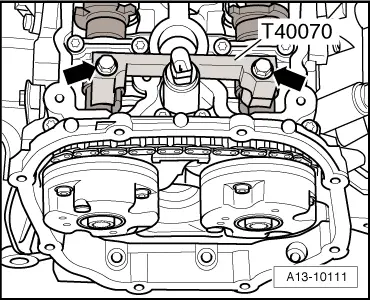

| t | Camshaft clamp -T40070- (2x) |

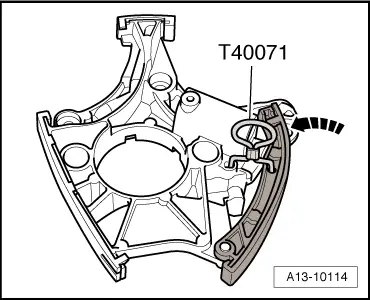

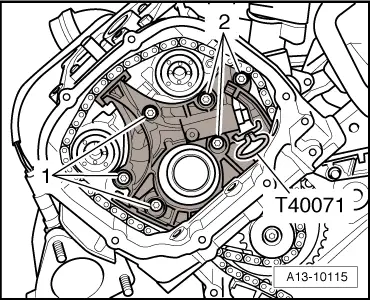

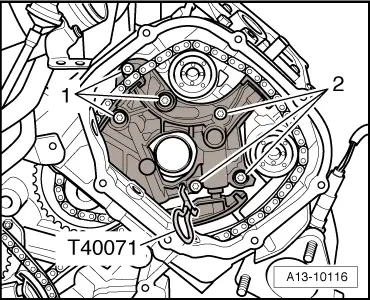

| t | Locking pin -T40071- (2x) |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

| Component | Nm | ||||||

| Chain tensioner to cylinder head | 9 | ||||||

| Camshaft bolts | 80 + 90° 1)2) | ||||||

| Screw plug in cylinder block | 14 3) | ||||||

| |||||||

WARNING

WARNING