| –

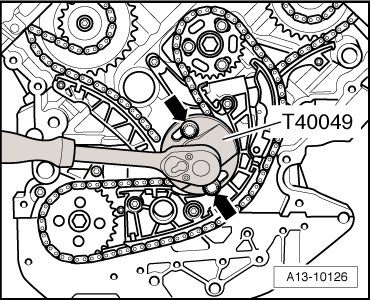

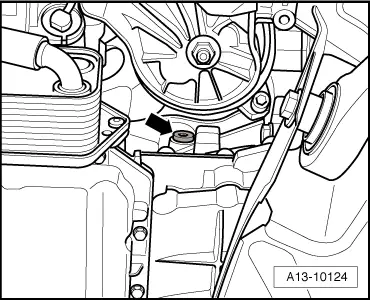

| Install chain tensioner with chain and balance shaft sprocket. |

| –

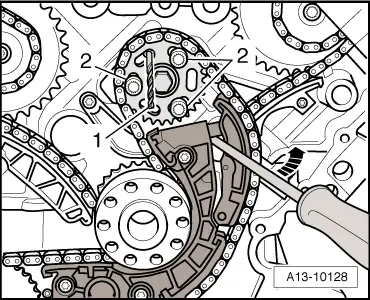

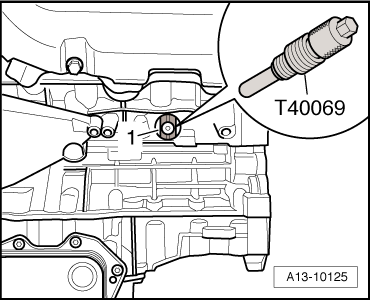

| Wrap insulating tape around tip and shaft of 8 mm Ø drill bit to avoid cuts. |

| –

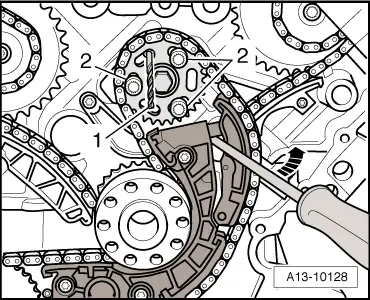

| Lock balance shaft in TDC position with Ø 8 mm drill bit -item 1-. |

| l

| The elongated holes in the balance shaft sprocket must be aligned centrally over the threaded holes in the balance shaft. If necessary move chain one tooth further. |

| –

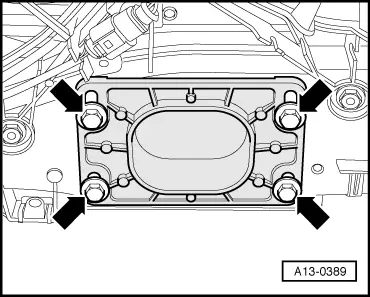

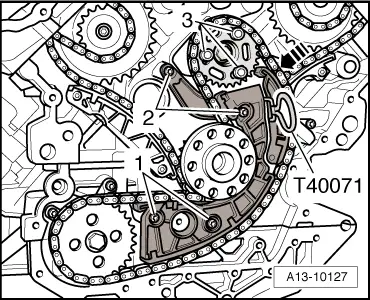

| Tighten bolts for chain tensioner. |

| –

| Screw in bolts -2- for chain sprocket, but do not tighten. |

| l

| It should just be possible to turn the sprocket on the balance shaft without axial movement. |

| –

| Pull locking pin -T40071- out to release chain tensioner. |

| –

| Press against guide rail of chain tensioner -arrow- using a screwdriver, and at the same time tighten bolts -2- securing chain sprocket. |

| –

| Pull drill bit -item 1- out of balance shaft. |

| Perform further installation in reverse order, paying attention to the following: |

| –

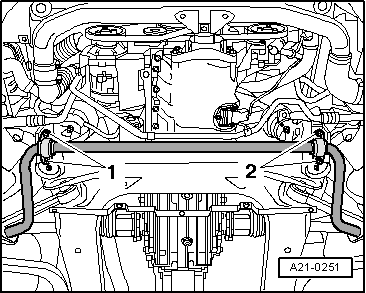

| Install timing chain cover (bottom) → Chapter. |

| –

| Install timing chain covers (left and right) → Chapter. |

| –

| Install crankshaft oil seal (timing chain end) → Chapter. |

| –

| Vehicles with multitronic gearbox: Install flywheel → Chapter and damper unit → Chapter. |

| –

| Vehicles with automatic gearbox: install drive plate → Chapter. |

|

|

|

Note

Note

WARNING

WARNING Caution

Caution