A4 Mk2

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

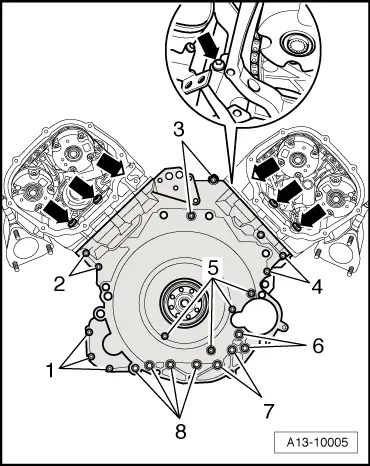

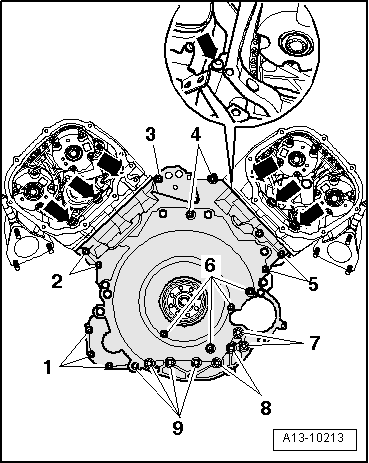

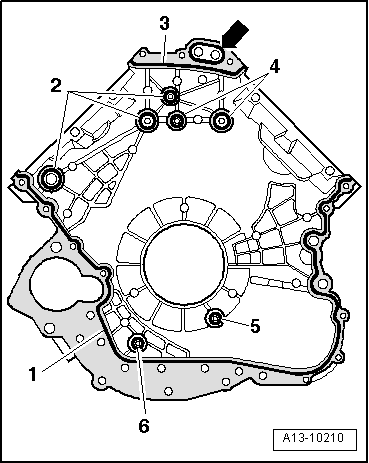

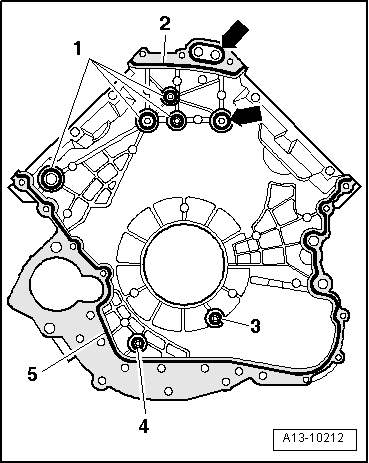

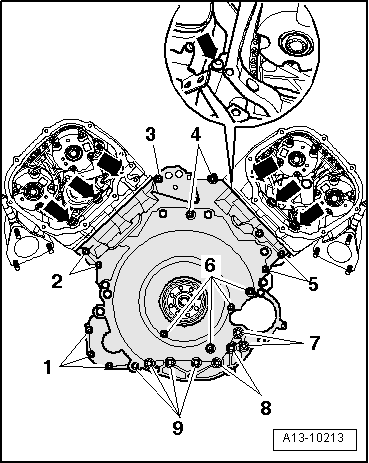

| Component | Nm | |||||||

| Timing chain cover (bottom) to engine | M6 | 9 1) | ||||||

| M7 | 16 | |||||||

| M8 | 20 | |||||||

| Timing chain covers (left and right) to engine | 5 + 90° 2)3) | |||||||

| Bracket for electrical connectors to cylinder head | 9 | |||||||

| ||||||||

WARNING

WARNING Caution

Caution