A4 Mk2

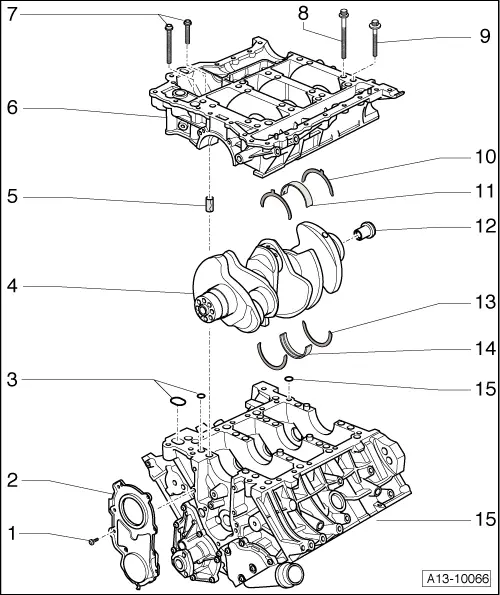

| Crankshaft - exploded view of components |

Note

Note| When carrying out repairs, secure engine to engine and gearbox support -VAS 6095- → Chapter. |

| 1 - | 9 Nm |

| q | Tighten in stages and in diagonal sequence |

| 2 - | Sealing flange (pulley end) |

| q | Renewing → Chapter |

| 3 - | Seals |

| q | Different versions available → Electronic parts catalogue |

| q | Renew |

| 4 - | Crankshaft |

| q | Measuring axial clearance → Chapter |

| q | Measuring radial clearance → Chapter |

| q | Do not rotate the crankshaft when checking the radial clearance |

| q | Crankshaft dimensions → Chapter |

| 5 - | Dowel sleeve |

| q | 4 x |

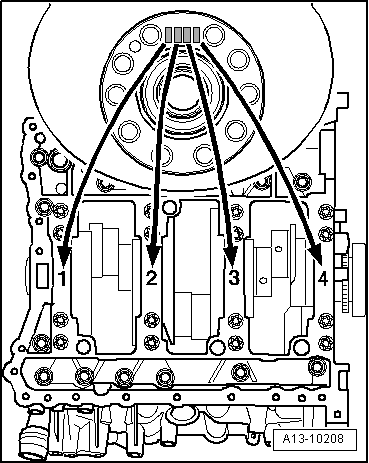

| q | Inserting in retaining frame → Fig. |

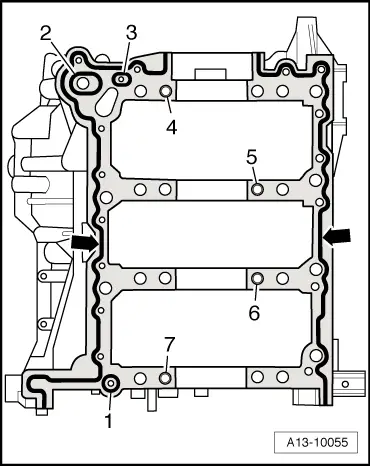

| 6 - | Retaining frame |

| q | To remove, detach guide rail → Item for drive chain for valve gear |

| q | Applying sealant → Fig. |

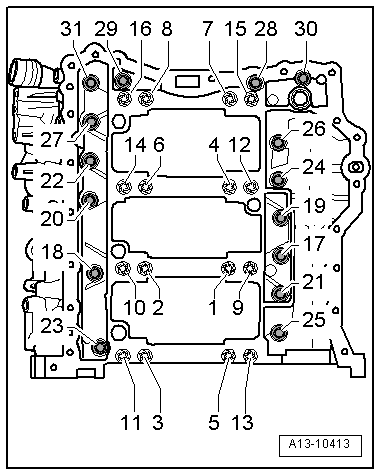

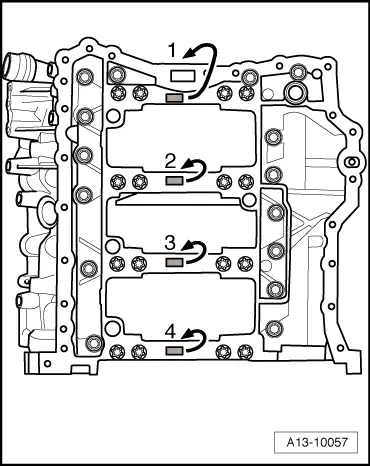

| q | Tightening sequence for securing bolts → Fig. |

| 7 - | Bolt |

| q | For sealing surfaces: cylinder block/retaining frame |

| q | Differing bolt lengths and bolt heads |

| q | Tightening sequence → Fig. |

| 8 - | Bolt (long, large collar) |

| q | For retaining frame (inner row) |

| q | Tightening sequence → Fig. |

| 9 - | Bolt (short, small collar) |

| q | For retaining frame (outer row) |

| q | Tightening sequence → Fig. |

| 10 - | Thrust washer |

| q | Only fitted on 3rd crankshaft bearing |

| q | Oil grooves face outwards |

| q | Make sure it engages in retaining frame |

| q | Measuring axial clearance of crankshaft → Chapter |

| 11 - | Bearing shell |

| q | For retaining frame (without oil groove) |

| q | Do not interchange used bearing shells (mark positions) |

| q | Note installation position |

| q | Install new bearing shells for retaining frame with correct coloured markings → Fig. |

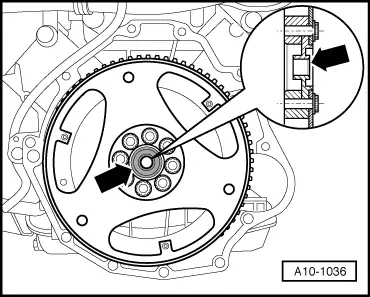

| 12 - | Centralising disc |

| q | For vehicles with automatic gearbox 09L → Fig. |

| 13 - | Thrust washer |

| q | Only fitted on 3rd crankshaft bearing |

| q | Oil grooves face outwards |

| q | Make sure it engages in retaining frame |

| q | Measuring axial clearance of crankshaft → Chapter |

| 14 - | Bearing shell |

| q | For cylinder block (with oil groove) |

| q | Do not interchange used bearing shells (mark positions) |

| q | Note installation position |

| q | Install new bearing shells for the cylinder block with the correct coloured markings → Fig. |

| 15 - | O-ring or seal |

| q | Depending on version → Electronic parts catalogue |

| q | Renew |

| 16 - | Cylinder block |

Note

Note

|

|

|

|

|

|

| Bearing No. | Code letter on retaining frame | Colour coding of bearing | |

| 1 | G | = | Red |

| B | = | Yellow | |

| S | = | Blue | |

| 2 … 4 | G | = | Yellow |

| B | = | Blue | |

| S | = | Black | |

|

| Code letter on retaining frame | Colour coding of bearing | |

| R | = | Red |

| G | = | Yellow |

| B | = | Blue |

| S | = | Black |

|

|

| Bearing No. | Letter on crankshaft | Colour coding of bearing | |

| 1 | G | = | Red |

| B | = | Yellow | |

| S | = | Blue | |

| 2 … 4 | G | = | Yellow |

| B | = | Blue | |

| S | = | Black | |

|

| Letter on crankshaft | Colour coding of bearing | |

| R | = | Red |

| G | = | Yellow |

| B | = | Blue |

| S | = | Black |