A4 Mk2

| Checking compression |

| Special tools and workshop equipment required |

| t | Spark plug socket and extension -3122 B- |

| t | Compression tester -V.A.G 1763- |

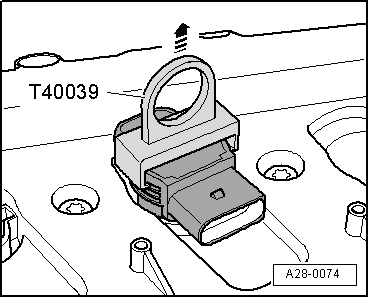

| t | Puller -T40039- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

| Compression pressure | bar |

| When new | 11.0 … 14.0 |

| Wear limit | 10.0 |

| Difference between cylinders | 3.0 (maximum) |

|

| Component | Nm |

| Hose clips (9 mm wide) | 3 |