A4 Mk2

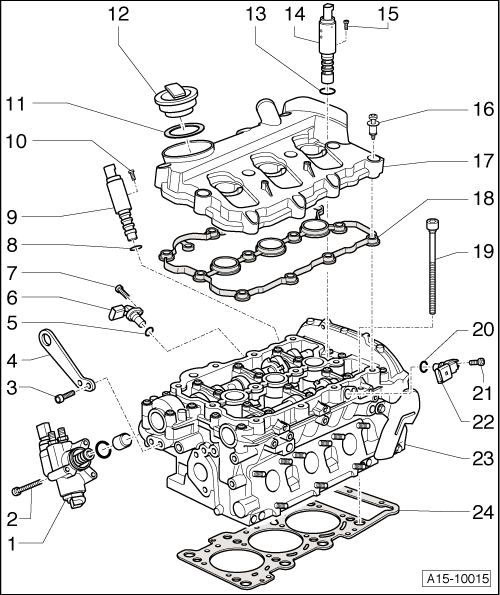

| Cylinder head - exploded view of components |

Note

Note| t | Illustration shows left cylinder head. |

| t | Both cylinder heads can be removed and installed with the engine still installed. |

| 1 - | High-pressure pump |

| q | Removing and installing → Rep. Gr.24 |

| 2 - | 9 Nm |

| 3 - | 20 Nm |

| 4 - | Lifting eye |

| 5 - | O-ring |

| q | Renew |

| 6 - | Hall sender for inlet camshaft |

| q | Cylinder bank 1 (right-side) Hall sender -G40- |

| q | Cylinder bank 2 (left-side) Hall sender 2 -G163- |

| 7 - | 8 Nm + 90° (1/4 turn) further |

| q | Renew |

| 8 - | O-ring |

| q | Renew |

| 9 - | Solenoid valve for camshaft control (inlet side) |

| q | Cylinder bank 1 (right-side) camshaft control valve 1 -N205- |

| q | Cylinder bank 2 (left-side) - camshaft control valve 2 -N208- |

| 10 - | 2.5 Nm |

| 11 - | Gasket |

| q | Renew if damaged or leaking |

| 12 - | Filler cap |

| 13 - | O-ring |

| q | Renew |

| 14 - | Solenoid valve for camshaft control (exhaust side) |

| q | Cylinder bank 1 (right-side) - exhaust camshaft control valve 1 -N318- |

| q | Cylinder bank 2 (left-side) - exhaust camshaft control valve 2 -N319- |

| 15 - | 2.5 Nm |

| 16 - | Special bolt, 9 Nm |

| q | Renew if damaged or leaking |

| q | Note correct sequence when tightening → Anchor |

| 17 - | Cylinder head cover |

| q | Removing and installing: left-side → Chapter, right-side → Chapter |

| 18 - | Gasket for cylinder head cover |

| q | Renew if damaged or leaking |

| 19 - | Cylinder head bolt |

| q | Renew |

| q | Note correct sequence when loosening → Anchor |

| q | Note correct sequence when tightening → Anchor |

| 20 - | O-ring |

| q | Renew |

| 21 - | 8 Nm + 90° (1/4 turn) further |

| q | Renew |

| 22 - | Hall sender for exhaust camshaft |

| q | Cylinder bank 1 (right-side) Hall sender 3 -G300- |

| q | Cylinder bank 2 (left-side) Hall sender 4 -G301- |

| 23 - | Cylinder head |

| q | Removing → Chapter |

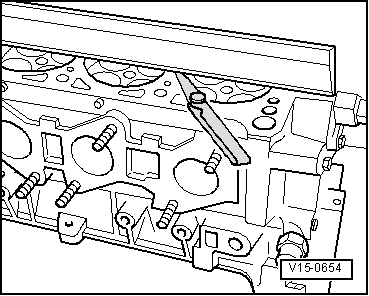

| q | Checking for distortion → Fig. |

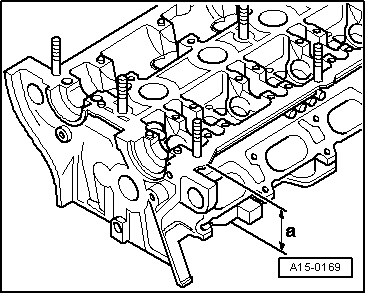

| q | Machining limit → Fig. |

| q | Installing → Anchor |

| q | If renewed, change coolant and engine oil |

| 24 - | Cylinder head gasket |

| q | Renewing → Chapter „Removing and installing cylinder head“ |

| q | Installation position: Part No. towards cylinder head |

| q | If renewed, change coolant and engine oil |

|

|

|

|