| –

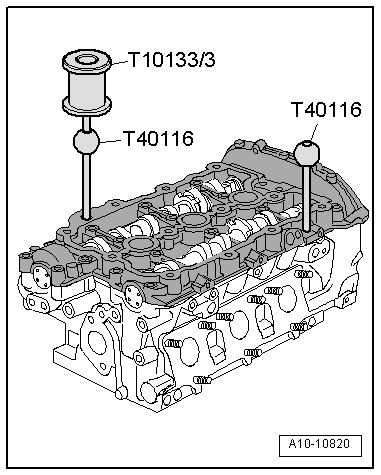

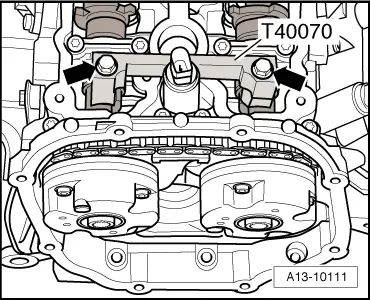

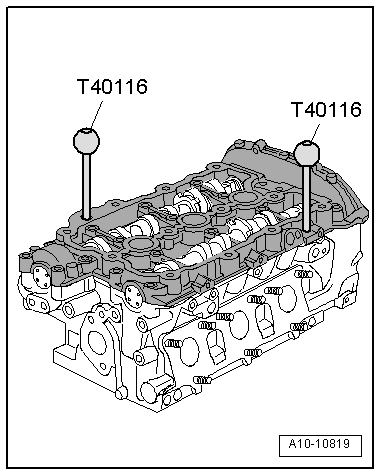

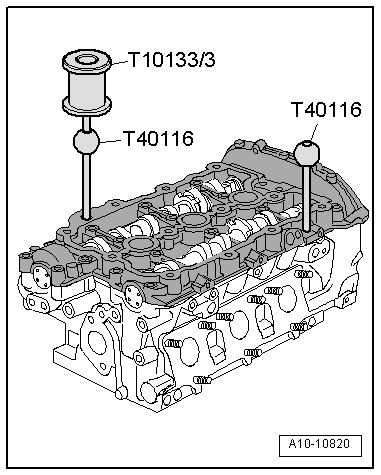

| Use impact extractor attachment -T10133/3- to pull out locating pins -T40116-. |

| Perform further installation in reverse order, paying attention to the following: |

Note | t

| After installing camshafts, wait for approx. 30 minutes before starting engine. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations by hand to ensure that none of the valves make contact when the starter is operated. |

| –

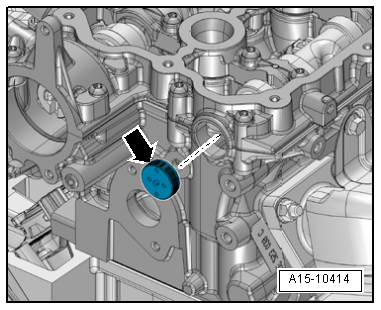

| Install exhauster pump for brake servo → Chapter. |

| –

| Install timing chain covers (left and right) → Chapter. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution