A4 Mk2

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

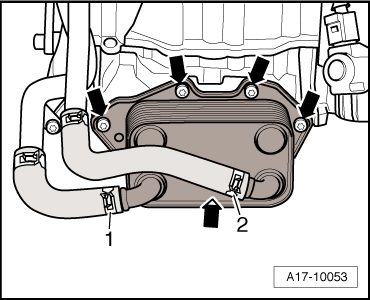

| Component | Nm | ||||||

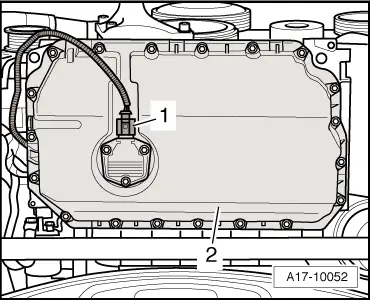

| Oil cooler to sump (top section) | 9 | ||||||

| Sump (bottom section), aluminium version to sump (top section) | 9 1) | ||||||

| Sump (bottom section), sheet-metal version to sump (top section) | 5 + 90° 1)2)3) | ||||||

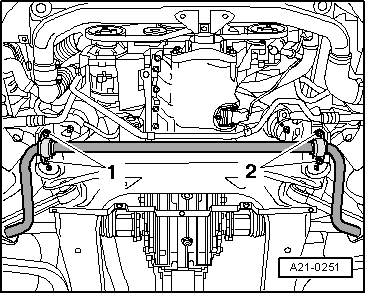

| Bracket to sump | 9 | ||||||

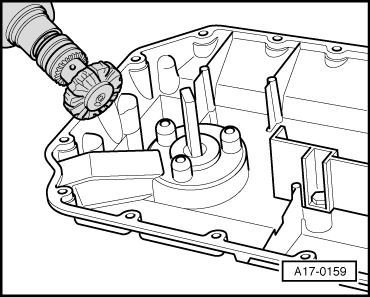

| Oil drain plug | 30 | ||||||

| |||||||

WARNING

WARNING