A4 Mk2

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

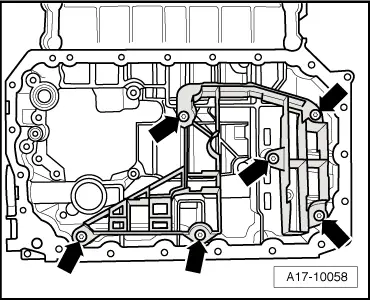

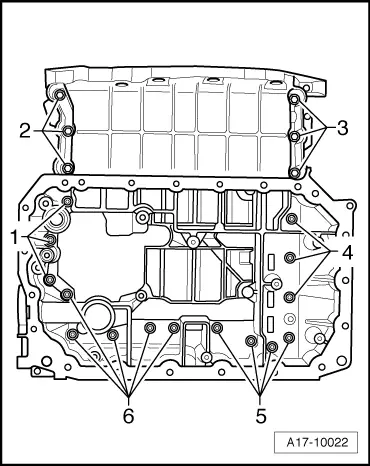

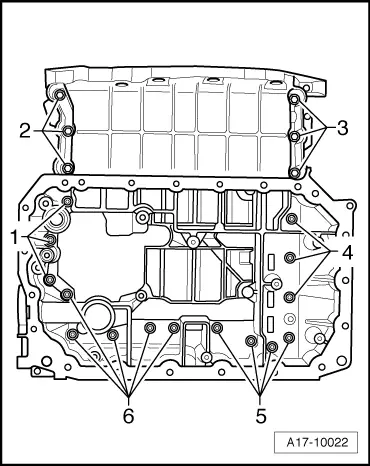

| Component | Nm | ||||

| Sump (top section) to cylinder block | 16 1) | ||||

| Baffle plate (top) to sump (top section) | 9 2) | ||||

| Baffle plate (bottom) to sump (top section) | 9 | ||||

| Oil drain plug | 30 | ||||

| |||||

WARNING

WARNING