A4 Mk2

| Removing and installing toothed belt |

| Special tools and workshop equipment required |

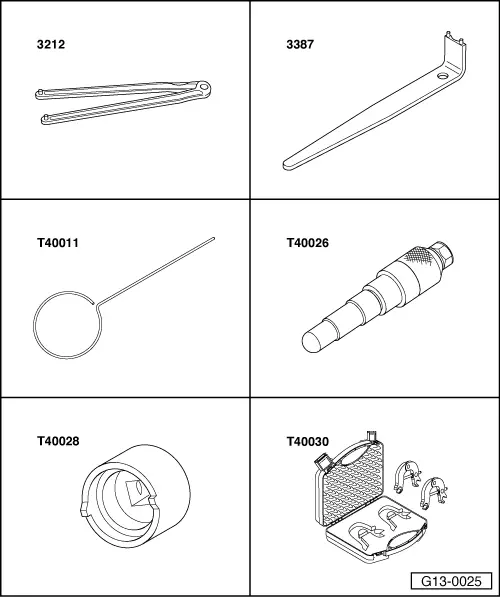

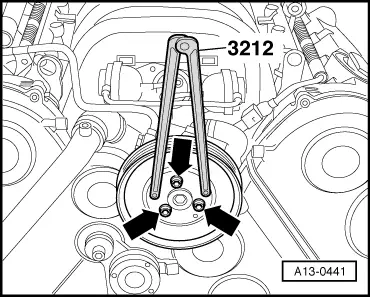

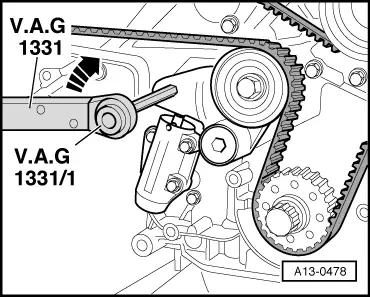

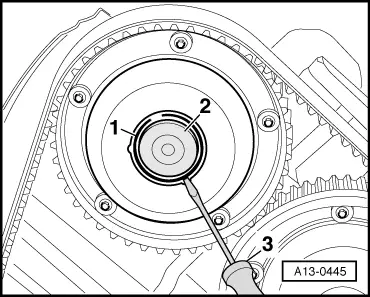

| t | Pin wrench -3212- |

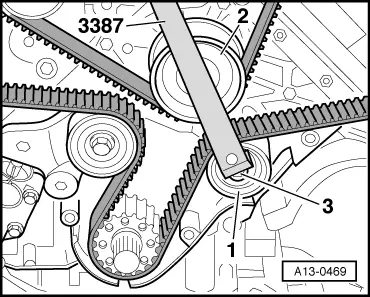

| t | Pin wrench -3387- |

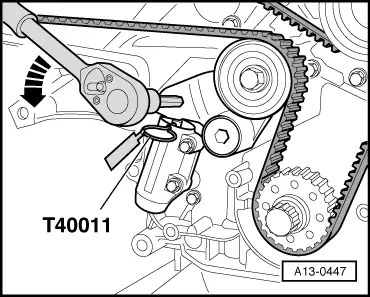

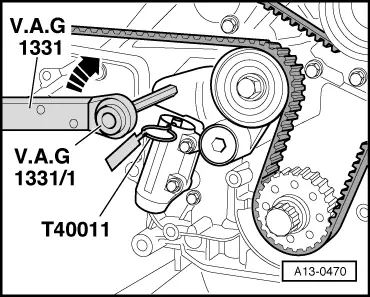

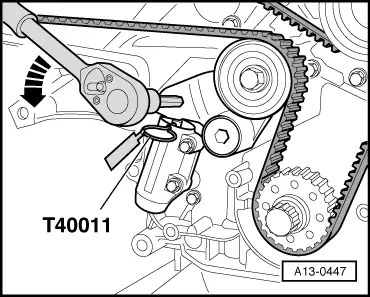

| t | Locking pin -T40011- |

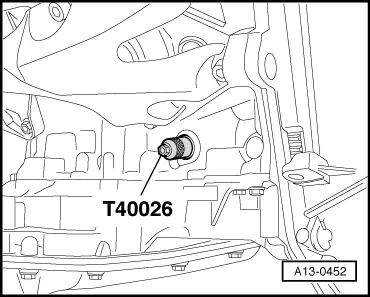

| t | Locking pin -T40026- |

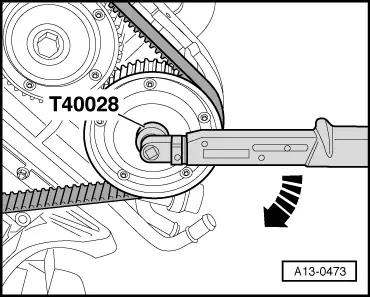

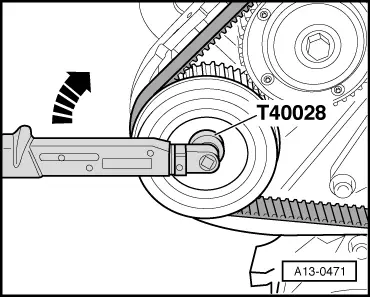

| t | Socket -T40028- |

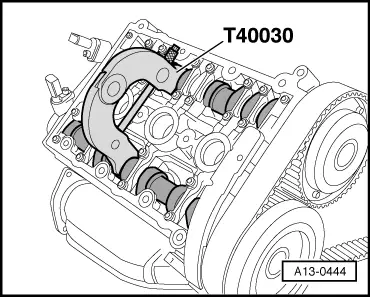

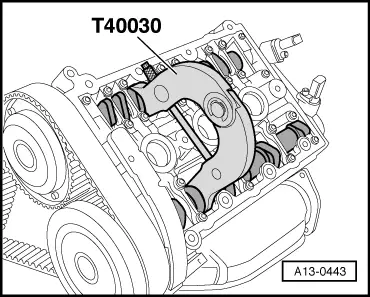

| t | Camshaft clamp -T40030- |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Component | Nm |

| Eccentric adjuster to front sealing flange | 45 |

| Camshaft sprocket to camshaft | 100 |

| Sealing plug in cylinder block | 25 |

| Pulley to power steering pump | 23 |

Caution

Caution