A4 Mk2

| Removing engine |

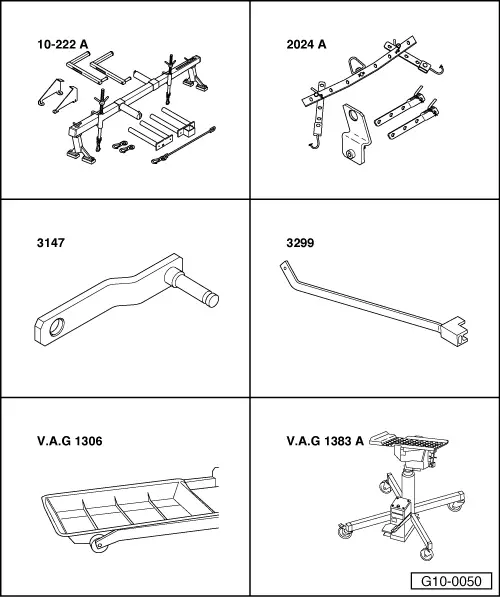

| Special tools and workshop equipment required |

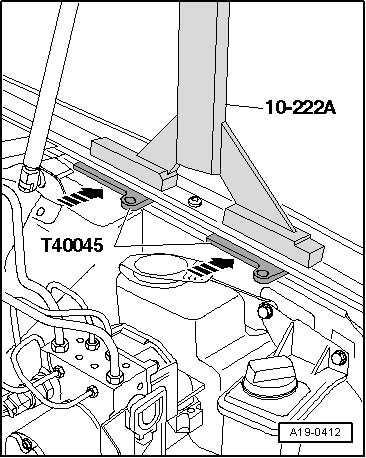

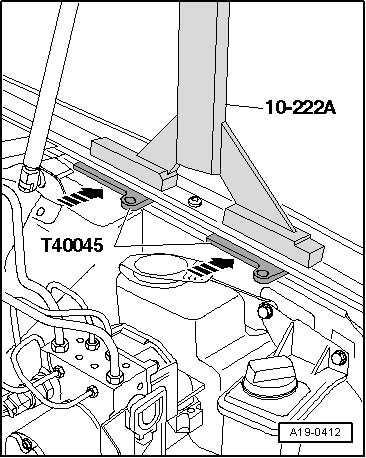

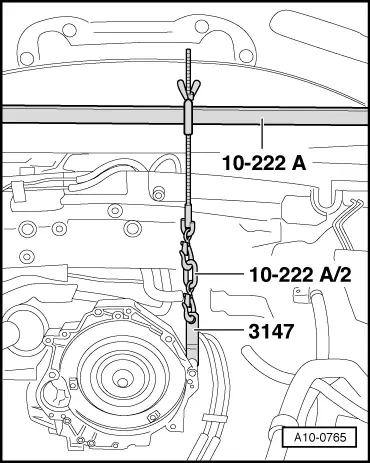

| t | Support bracket -10-222 A- |

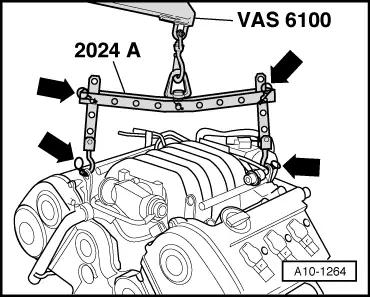

| t | Lifting tackle -2024 A- |

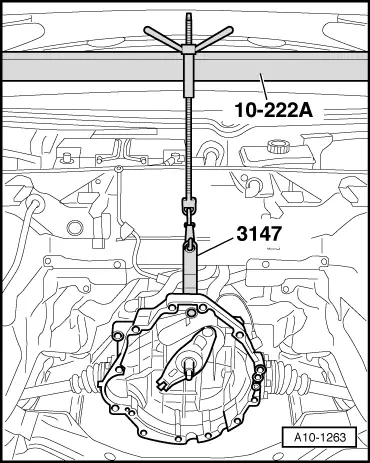

| t | Gearbox support -3147- |

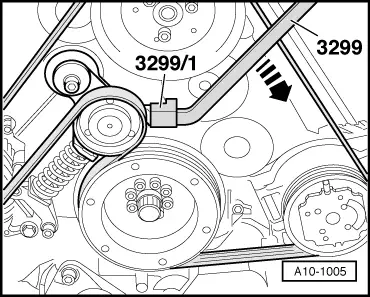

| t | Poly V-belt lever -3299- with bracket -3299/1- |

| t | Drip tray for workshop hoist -VAS 6208- or -V.A.G 1306- |

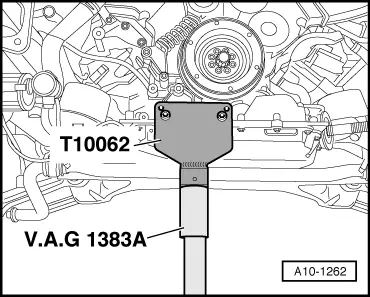

| t | Engine and gearbox jack -V.A.G 1383 A- |

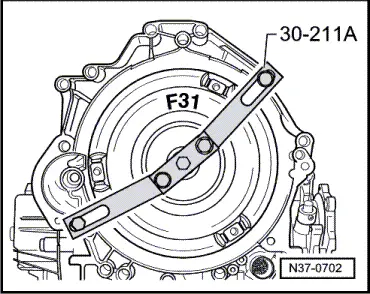

| t | Support bridge -30-211 A- for vehicles with automatic gearbox 01V |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Workshop hoist -VAS 6100- |

| t | Support -T10062- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note |

|

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

Note

Note

|

|

|

|

|

|

Caution

Caution WARNING

WARNING