| Checking hydraulic bucket tappets |

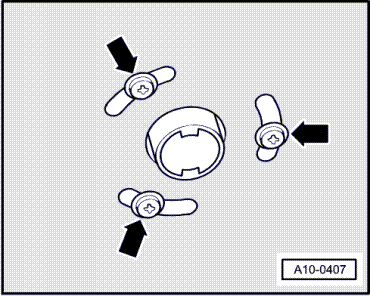

| Special tools and workshop equipment required |

Note | t

| Hydraulic bucket tappets cannot be serviced. |

| t

| Irregular valve noises when starting engine are normal. |

| –

| Start engine and leave it running until coolant temperature has reached approx. 80 °C. |

| –

| Increase engine speed to approx. 2500 rpm for 2 minutes (perform road test if necessary). |

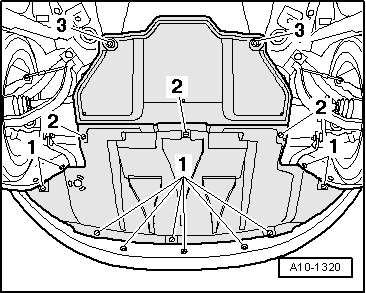

Note | If the irregular valve noises stop but recur repeatedly during short trips, renew the oil retention valve. Fitting location of oil retention valve: beneath cover on intake manifold → Item. |

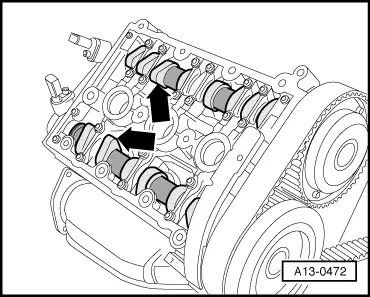

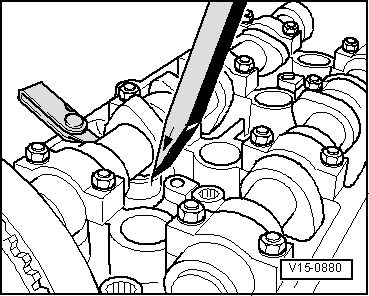

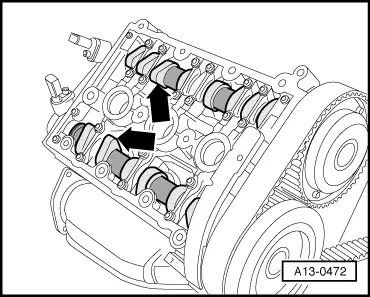

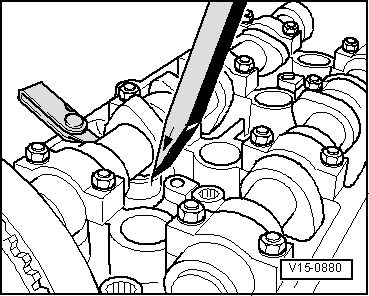

| If the hydraulic tappets are still noisy, locate defective tappet as follows: |

|

|

|

Note

Note Note

Note

Note

Note Note

Note