A4 Mk2

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

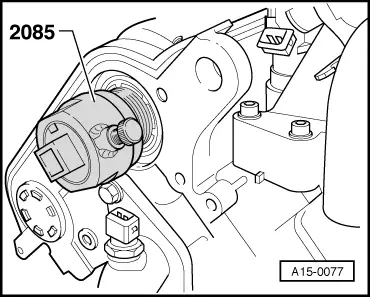

| Component | Nm |

| Hall sender rotor to camshaft | 25 |

| Hall sender housing to cylinder head | 10 |