A4 Mk2

| Exhaust system - exploded view |

| 1 - | Centre silencer |

| q | Combined in one unit with rear silencer as original equipment. Can be renewed individually for repair purposes |

| q | Cutting point → Anchor |

| q | Align exhaust system so it is free of stress → Chapter |

| 2 - | 23 Nm |

| 3 - | Mounting |

| q | Renew if damaged |

| 4 - | 27 Nm |

| q | Renew |

| 5 - | Exhaust manifold |

| q | For cylinder bank 1 (right-side) |

| q | Removing and installing → Chapter |

| 6 - | Gasket |

| q | Renew |

| 7 - | Lambda probe (before catalytic converter), 55 Nm |

| q | For cylinder bank 1 (right-side) |

| q | Threads of new Lambda probes are already greased with assembly paste; the paste must not get into the slots on the probe body |

| q | When re-using the old Lambda probe, grease thread with high-temperature paste lubricant; the paste must not get into the slots of the probe body. High-temperature paste → Parts catalogue |

| 8 - | Lambda probe (before catalytic converter), 55 Nm |

| q | For cylinder bank 2 (left-side) |

| q | Threads of new Lambda probes are already greased with assembly paste; the paste must not get into the slots on the probe body |

| q | When re-using the old Lambda probe, grease thread with high-temperature paste lubricant; the paste must not get into the slots of the probe body. High-temperature paste → Parts catalogue |

| 9 - | 27 Nm |

| q | Renew |

| 10 - | Exhaust manifold |

| q | For cylinder bank 2 (left-side) |

| q | Removing and installing → Chapter |

| 11 - | Gasket |

| q | Renew |

| 12 - | Lambda probe (after catalytic converter), 55 Nm |

| q | For cylinder bank 2 (left-side) |

| q | Threads of new Lambda probes are already greased with assembly paste; the paste must not get into the slots on the probe body |

| q | When re-using the old Lambda probe, grease thread with high-temperature paste lubricant; the paste must not get into the slots of the probe body. High-temperature paste → Parts catalogue |

| 13 - | Lambda probe (after catalytic converter), 55 Nm |

| q | For cylinder bank 1 (right-side) |

| 14 - | Front exhaust pipe with starter catalytic converter and main catalytic converter |

| q | For cylinder bank 2 (left-side) |

| q | With flexible joint |

| q | Do not bend flexible joint more than 10° - otherwise it can be damaged |

| q | Protect against knocks and impact |

| q | Align exhaust system so it is free of stress → Chapter |

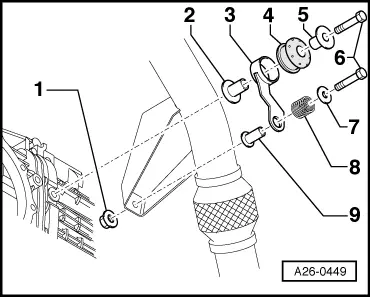

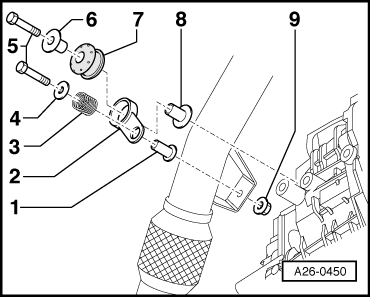

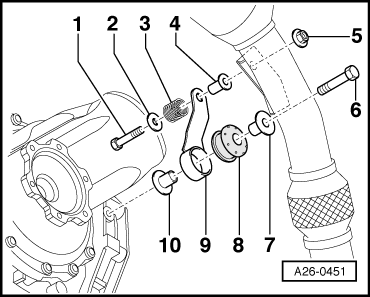

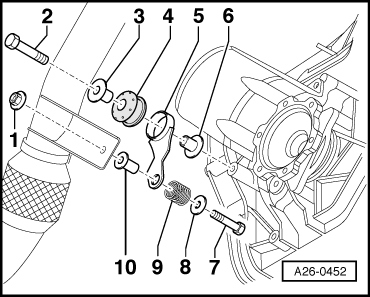

| q | Components of exhaust pipe mountings for vehicles with manual gearbox → Fig. |

| q | Components of exhaust pipe mountings for vehicles with automatic gearbox 01J → Fig. |

| q | Removing and installing → Chapter |

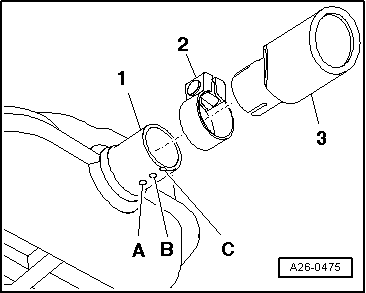

| 15 - | Clamp (front) |

| q | Align exhaust system so it is free of stress before tightening clamp → Chapter |

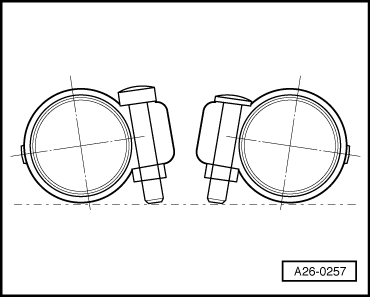

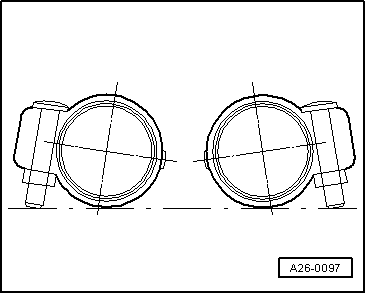

| q | Installation position → Fig. |

| q | Tighten bolt connections evenly. |

| 16 - | 40 Nm |

| 17 - | Front exhaust pipe with starter catalytic converter and main catalytic converter |

| q | For cylinder bank 1 (right-side) |

| q | With flexible joint |

| q | Do not bend flexible joint more than 10° - otherwise it can be damaged |

| q | Protect against knocks and impact |

| q | Align exhaust system so it is free of stress → Chapter |

| q | Components of exhaust pipe mountings for vehicles with manual gearbox → Fig. |

| q | Components of exhaust pipe mountings for vehicles with automatic gearbox 01J → Fig. |

| q | Removing and installing → Chapter |

| 18 - | Rear silencer |

| q | For left side of vehicle |

| q | Combined in one unit with centre silencer as original equipment. Can be renewed individually for repair purposes |

| q | Cutting point → Anchor |

| q | Renewing tailpipe → Fig. |

| q | Align exhaust system so it is free of stress → Chapter |

| 19 - | Mounting |

| q | Renew if damaged |

| 20 - | 23 Nm |

| 21 - | Rear silencer |

| q | For right side of vehicle |

| q | Combined in one unit with centre silencer as original equipment. Can be renewed individually for repair purposes |

| q | Cutting point → Anchor |

| q | Renewing tailpipe → Fig. |

| q | Align exhaust system so it is free of stress → Chapter |

| 22 - | 23 Nm |

| 23 - | Clamp (rear) |

| q | For separate replacement of centre and rear silencers |

| q | Align exhaust system so it is free of stress before tightening clamp → Chapter |

| q | Installation position → Fig. |

| q | Tighten bolt connections evenly. |

| 24 - | 40 Nm |

| 25 - | Mounting |

| q | Renew if damaged |

| 26 - | 23 Nm |

|

|

|

|

|

|

|

|

|

|

|

|