A4 Mk2

Note

Note

|

|

|

|

|

Note

Note

|

|

|

|

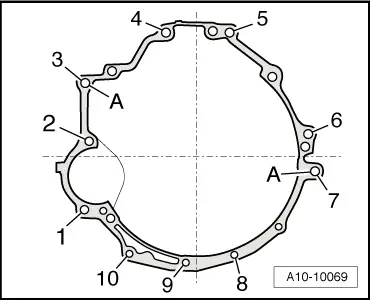

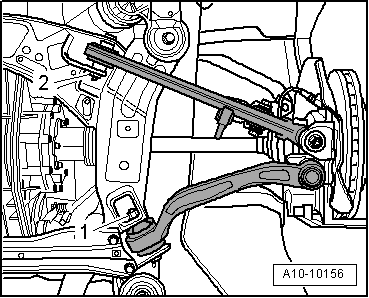

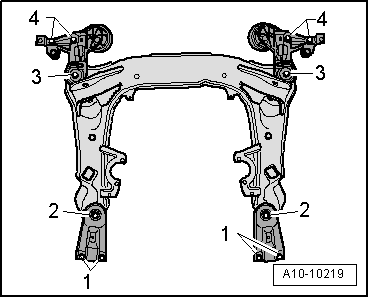

| Item | Bolt | Nm | ||

| 1 | M10x80 | 65 1) | ||

| 2 | M10x100 | 65 1) | ||

| 3 | M12x100 | 65 | ||

| 4, 5 | M12x110 | 65 | ||

| 6, 7 | M12x120 | 65 | ||

| 8, 9, 10 | M10x80 | 45 | ||

| A | Dowel sleeves for centralising | |||

| ||||

|

|

|

Note

Note

|

|

|

|

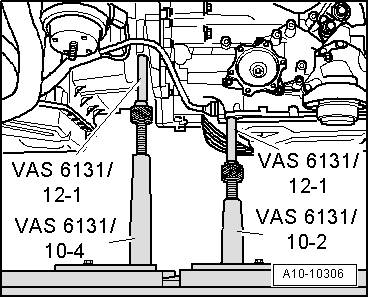

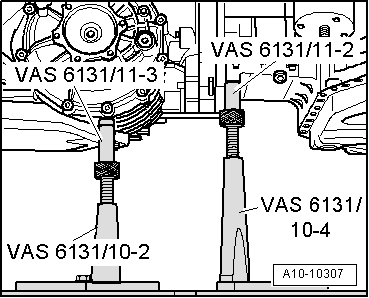

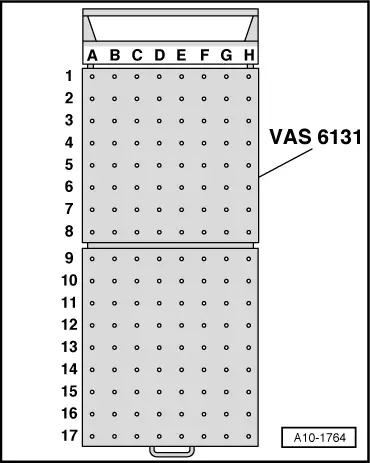

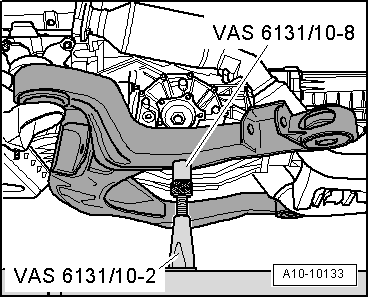

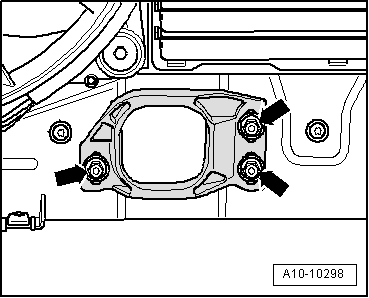

| Platform coordinates | Parts from support set for Audi -VAS 6131/10- | |||||||

| B3 1) | /10-1 | /10-4 | /10-5 | /10-11 | ||||

| F3 1) | /10-1 | /10-4 | /10-5 | /10-11 | ||||

| B10 | /10-1 | /10-2 | /10-5 | /10-8 2) | ||||

| G10 | /10-1 | /10-2 | /10-5 | /10-8 2) | ||||

| C15 1) | /10-1 | /10-3 | /10-5 | /10-12 | ||||

| F15 1) | /10-1 | /10-3 | /10-5 | /10-12 | ||||

| ||||||||

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

Note

Note

|

|

| Component | Nm | |||

| Bolts/nuts | M6 | 9 | ||

| M8 | 20 | |||

| M10 | 40 | |||

| M12 | 65 | |||

| Except for the following: | ||||

| Drive plate to torque converter | 85 1) | |||

| Terminal B+ to starter | 16 | |||

| Engine support to cylinder block | 40 | |||

| Gearbox mounting to subframe | 23 | |||

| Console for engine mounting to longitudinal member | 75 | |||

| Engine mounting to console for engine mounting | 23 | |||

| Drive shaft heat shield to gearbox | 23 | |||

| Torque reaction support to engine | 40 | |||

| Stop for torque reaction support to lock carrier | 28 | |||

| Hydraulic pressure pipe to power steering pump | 47 | |||

| Throttle valve module -J338- to intake manifold | 9 | |||

| Hose clips (9 mm wide) | 3 | |||

| Hose clips (13 mm wide) | 5.5 | |||

| ||||

Caution

Caution WARNING

WARNING