| –

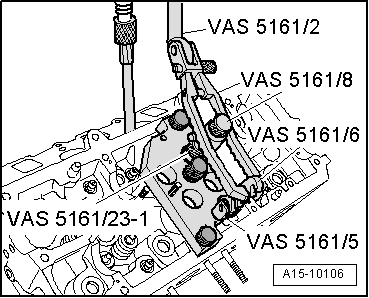

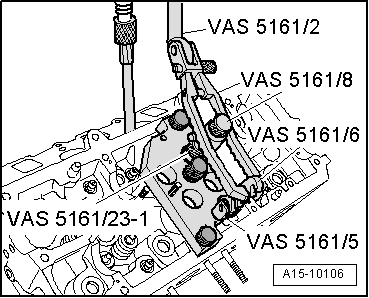

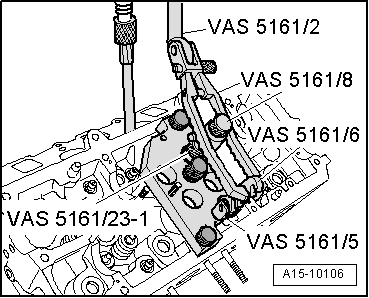

| Screw snap-in device -VAS 5161/6- with engaging fork -VAS 5161/5- into guide plate. |

| –

| Slide knurled spacer ring -VAS 5161/23-1- onto assembly cartridge -VAS 5161/8-. |

| –

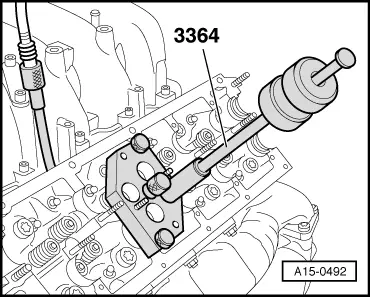

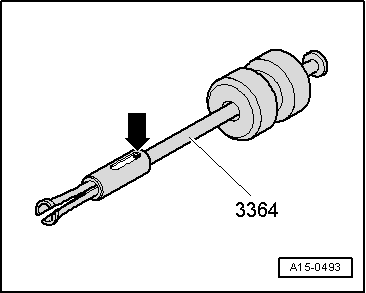

| Connect adapter to compressed air line using a commercially available connection piece, and apply constant air pressure. |

| l

| Minimum pressure: 6 bar |

| –

| Hook pressure fork -VAS 5161/2- into snap-in device and press assembly cartridge downwards. |

| –

| At the same time, turn knurled screw of assembly cartridge clockwise until tips engage in valve cotters. |

| –

| Move knurled screw back and forth slightly; the valve cotters are thus forced apart and taken up by the assembly cartridge. |

| –

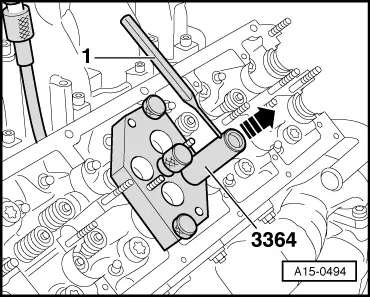

| Take off assembly cartridge with knurled spacer ring. |

| –

| Remove valve spring plate and valve spring. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note