A4 Mk2

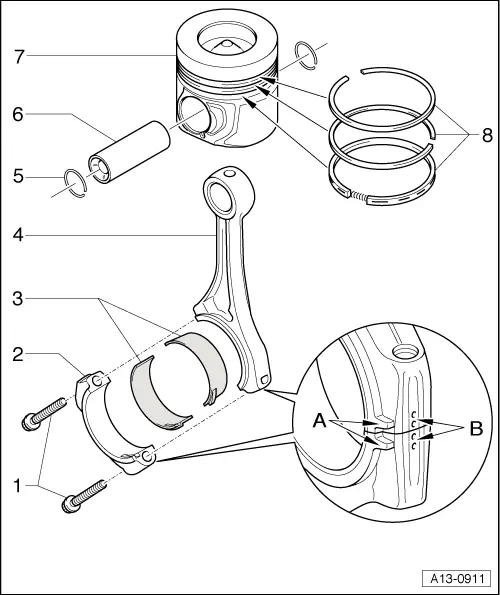

| Pistons and conrods - exploded view |

Note

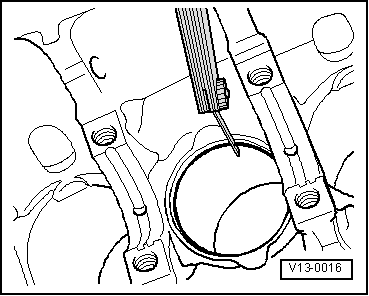

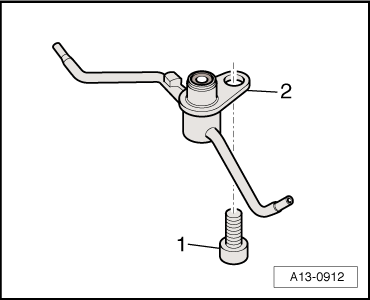

Note| Oil spray jet for piston cooling → Fig.. |

| 1 - | Conrod bolts, 30 Nm + turn 90° further |

| q | Renew |

| q | Lubricate threads and contact surface |

| q | To measure radial clearance, tighten to 30 Nm but do not turn further |

| 2 - | Conrod bearing cap |

| q | Do not interchange |

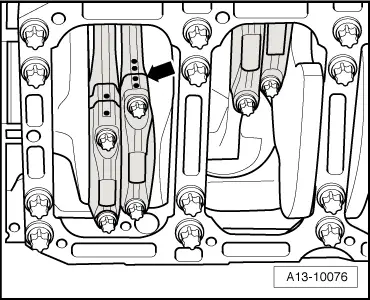

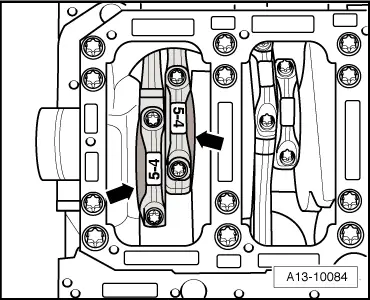

| q | Mark cylinder allocation in colour -B- → Fig. |

| q | Installation position: Note position of lugs on casting -A- |

| 3 - | Bearing shells |

| q | Note installation position |

| q | Renew used bearing shells |

| q | Measuring radial clearance → Chapter |

| q | For measuring radial clearance, tighten bolts -item 1- to 30 Nm but do not turn further |

| 4 - | Conrod |

| q | Only renew as a complete set |

| q | Mark cylinder allocation in colour -B- → Fig. |

| q | Installation position: Note position of lugs on casting -A- |

| q | Axial clearance for each conrod pair (when new): 0.20 … 0.44 mm |

| 5 - | Circlip |

| 6 - | Piston pin |

| q | If difficult to move, heat piston to approx. 60 °C |

| q | Remove and install using drift -VW 222 A- |

| 7 - | Piston |

| q | With combustion chamber |

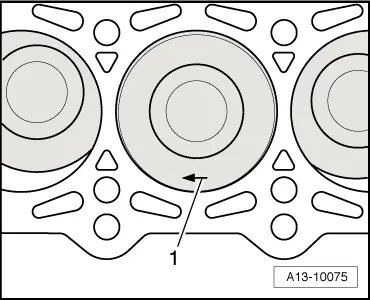

| q | Mark installation position and cylinder number → Fig. |

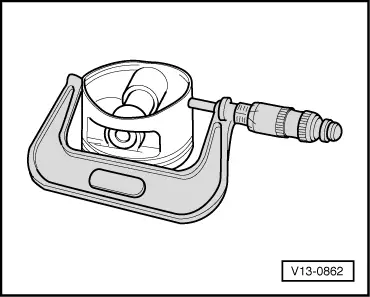

| q | Checking → Fig. |

| q | Install using piston ring clamp |

| q | If cracking is visible on piston skirt, renew piston |

| q | Piston and cylinder dimensions → Chapter |

| q | Checking piston projection at TDC → Chapter |

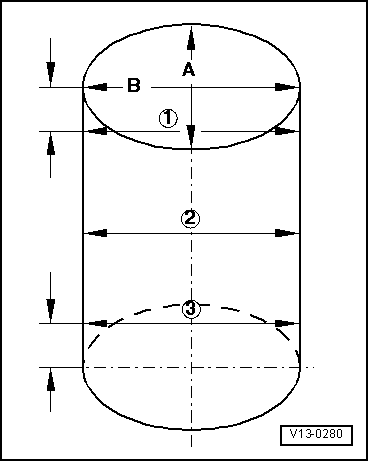

| q | Checking cylinder bore → Fig. |

| 8 - | Piston rings |

| q | Offset gaps by 120° |

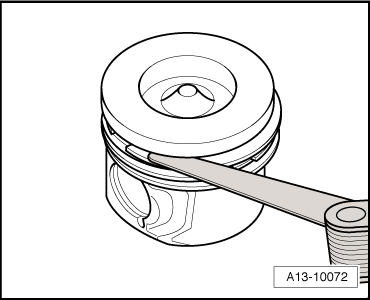

| q | Use piston ring pliers to remove and install |

| q | „TOP“ must face towards piston crown |

| q | Checking ring gap → Fig. |

| q | Checking ring-to-groove clearance → Fig. |

|

|

| Piston ring Dimensions in mm | New | Wear limit |

| 1st compression ring | 0.25 … 0.38 | 0.80 |

| 2nd compression ring | 0.70 … 0.90 | 1.30 |

| Oil scraper ring | 0.40 (maximum) | 0.70 |

|

|

| Piston ring Dimensions in mm | New | Wear limit |

| 1st compression ring | 0.120 … 0.160 | 0.175 |

| 2nd compression ring | 0.020 … 0.090 | 0.115 |

| Oil scraper ring | 0.020… 0.090 | 0.115 |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|