A4 Mk2

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

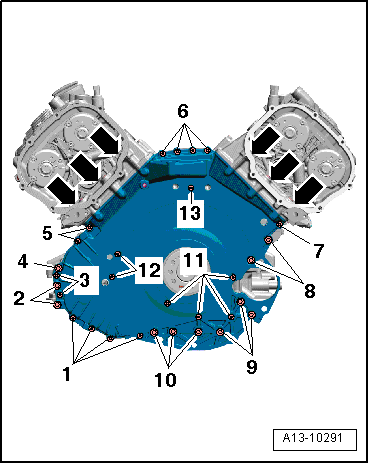

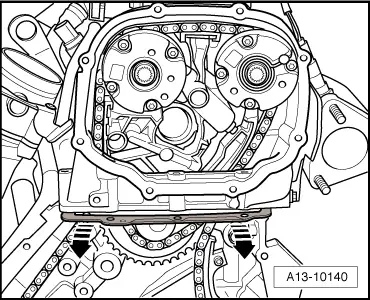

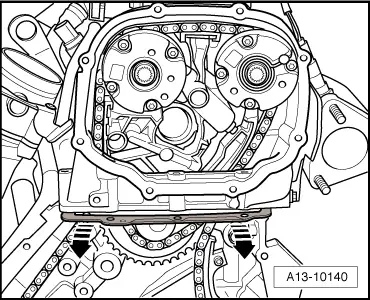

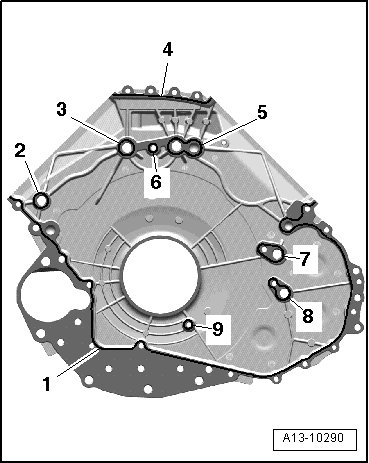

| Stage | Bolts | Tightening torque/tightening angle |

| 1. | -arrows- | 5 Nm |

| 2. | -1 … 13- | 8 Nm in diagonal sequence |

| 3. | -arrows- | 11 Nm |

| 4. | -2, 4, 8, 9, 10- | 22 Nm |

| 5. | -1, 3, 5, 6, 7, 11, 12, 13- | Turn 90° further in diagonal sequence |

| 6. | -arrows- | turn 90° further |

|

WARNING

WARNING Caution

Caution