A4 Mk2

|

Note

Note |

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note |

|

|

|

|

|

Note

Note

|

|

|

|

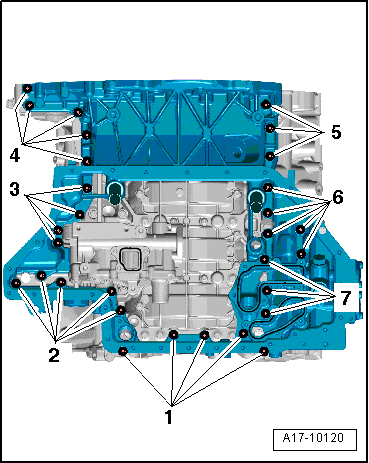

| Component | Nm |

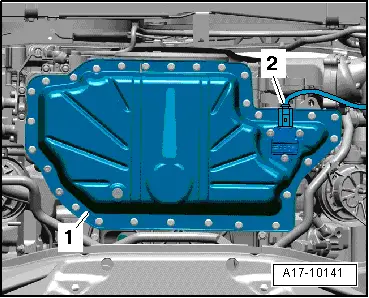

| Sump (top section) to retaining frame | 14 |

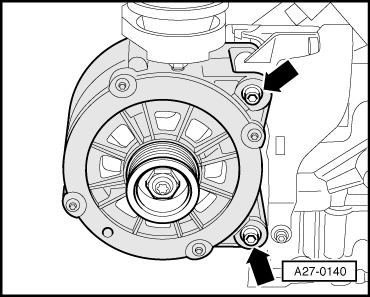

| Bracket for alternator to cylinder block | 22 |

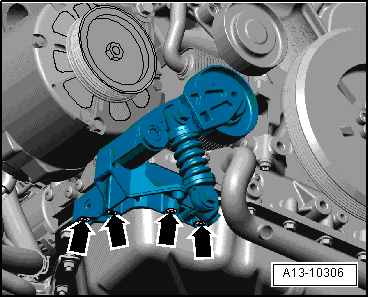

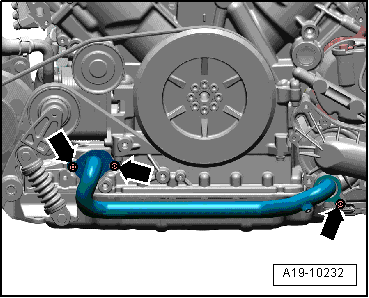

| Tensioner to sump (top section) | 9 |

WARNING

WARNING